You might be interested in

What is cold roll forming

Discover Sika’s cold forming process for custom metal profile production

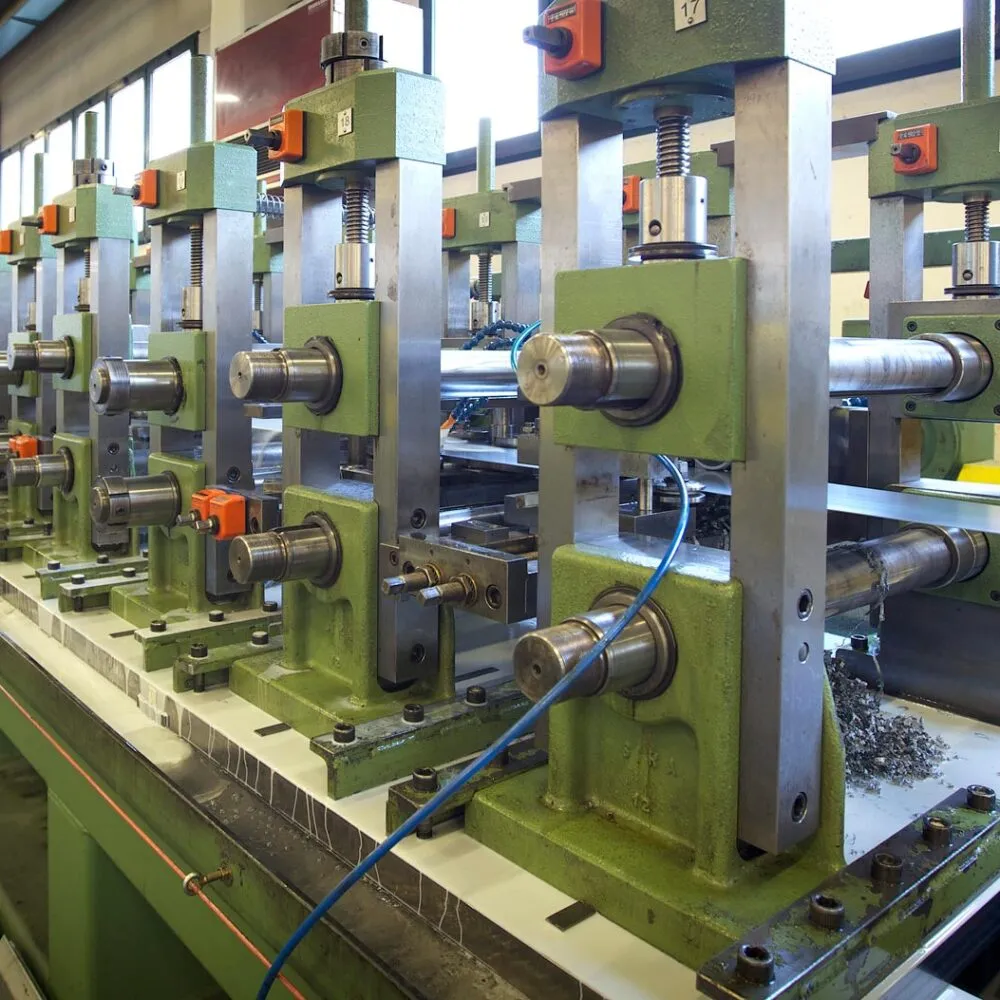

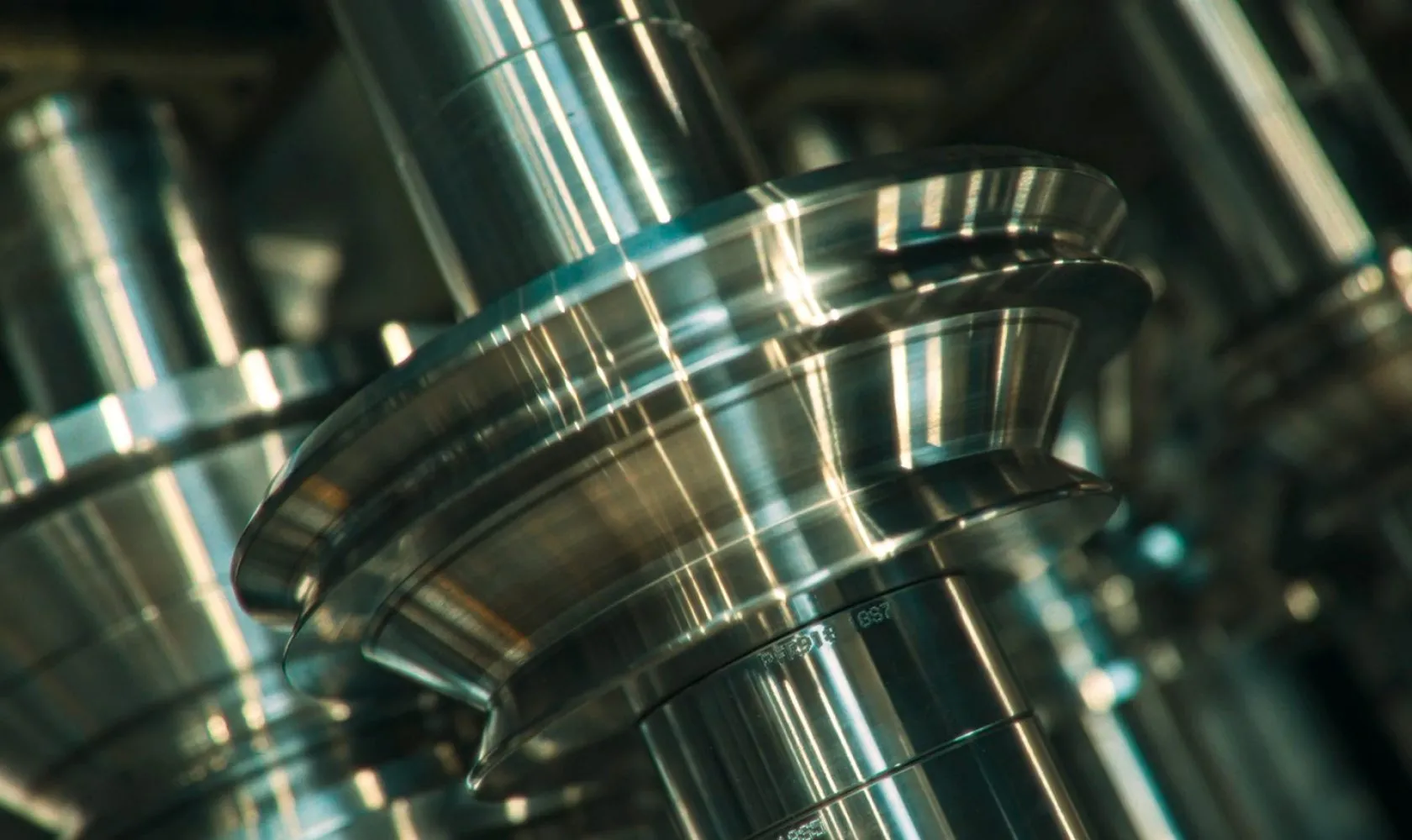

Cold roll forming is a modern and highly efficient technology used by Sika in the production of custom metal profiles. This process involves shaping steel strips at room temperature without the use of heat through a series of precisely shaped rollers that gradually form the desired geometry.

This continuous process enables the production of profiles with various cross-sections, millimetric precision, and customized features. It is ideal for a wide range of industrial applications, including the construction and automotive sectors.

Sika employs production lines designed to integrate all secondary operations such as punching, cutting, and marking directly inline, eliminating the need for additional processes and significantly reducing both time and production costs.

Main stages of cold roll forming according to Sika

Sika’s production process is designed to ensure efficiency and top quality. The key stages include:

- Coil Preparation: The metal strip is unwound and leveled in preparation for forming.

- Straightening: The material is corrected to eliminate curvature or surface defects.

- Pre-punching and Cutting: Holes and cuts are made as required, without interrupting the flow.

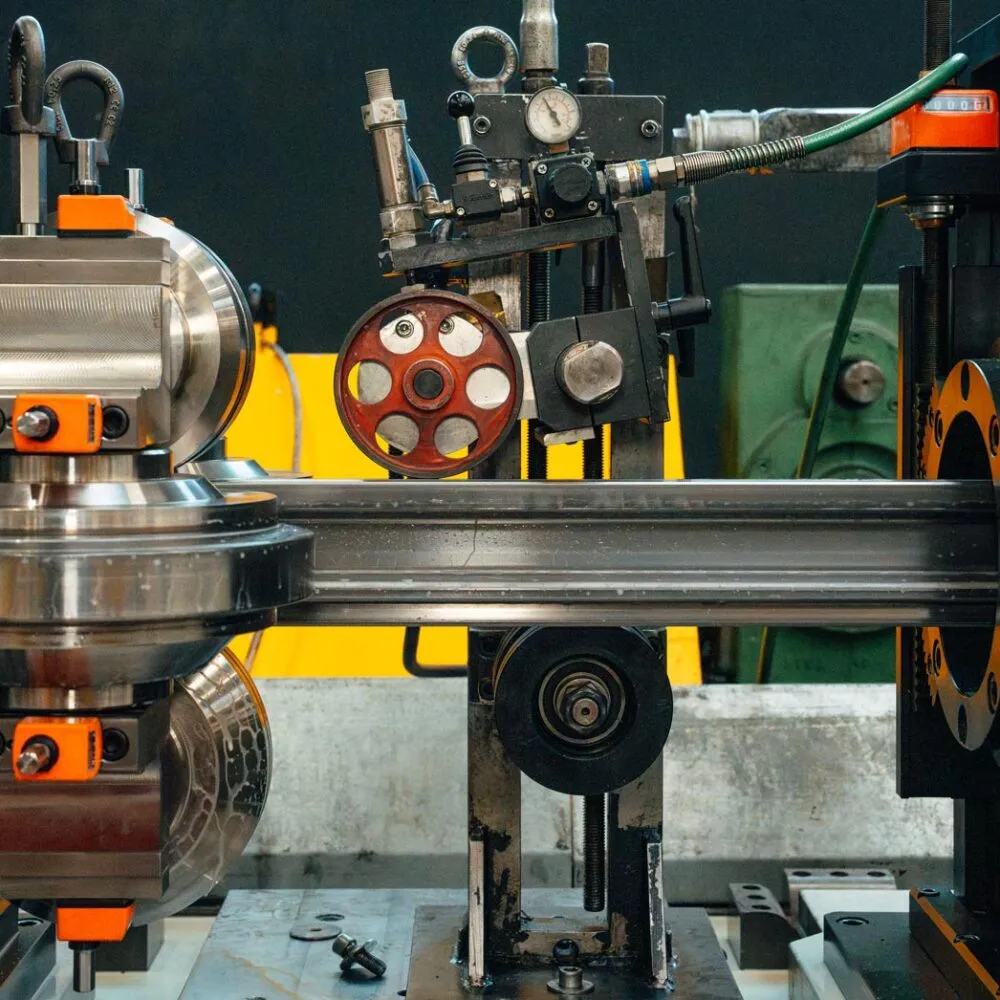

- Roll Forming: The strip passes through specialized rollers that shape it into the final profile.

- Continuous Welding: For closed profiles, high-precision welding ensures structural integrity.

- Final Straightening and Bending: Additional adjustments and custom bending are performed.

- Cutting and Secondary Operations: Profiles are cut to size and completed with optional finishing.

- Unloading: The finished product is collected and prepared for the next step in the supply chain.

Why choose cold roll forming with Sika?

Opting for cold roll forming means relying on a production process that guarantees:

- Efficient and continuous production of custom profiles

- Significant reduction in production times and costs

- High precision and consistent quality in the final products

- Greater sustainability thanks to low energy consumption

- Maximum flexibility and full customization according to client specifications

Sika’s innovation for an integrated manufacturing process

Thanks to the integration of advanced machinery including flatteners, laser welders, quality control systems, and inline coating units Sika offers a fully integrated and high-tech process. This approach allows for the delivery of ready-to-use, high-performance metal profiles with guaranteed durability.

Cold roll forming is the ideal solution for companies seeking superior-quality products, manufactured with precision and operational efficiency. With Sika, this process becomes synonymous with industrial innovation and long-term reliability.

The cold profiling process

Contact us to find out how Sika can support your project with high-quality specialty profiles and customized solutions.

Fill out the form to receive information or a no-obligation quote.