You might be interested in

News

Types of cold rolled steel: a complete guide for industrial applications

Understanding the different types of cold rolled steel is essential for businesses seeking high-performance metal profiles for construction, manufacturing, and design projects. Cold rolled steel undergoes a forming process at ambient temperature, resulting in superior surface finish, tighter tolerances, and enhanced mechanical properties compared to hot rolled alternatives. Each type of cold rolled steel offers specific characteristics that make it suitable for particular applications, environments, and performance requirements.

Stainless steel: corrosion resistance and hygiene

Stainless steel is one of the most versatile types of cold rolled steel, widely used in industries requiring exceptional corrosion resistance and hygienic properties. Available in various grades such as AISI 304, 316, 430, and 201, stainless steel forms a passive surface layer thanks to the presence of chromium and other alloying elements, protecting the material from oxidation and chemical attack. This makes it ideal for food processing, pharmaceutical manufacturing, medical equipment, and architectural applications where cleanliness and durability are paramount. Stainless steel profiles can undergo various finishes including polishing, brushing, and embossing to meet both aesthetic and functional requirements.

Galvanized steel: long-lasting protection

Galvanized steel represents another essential category among the types of cold rolled steel, offering robust protection against rust and environmental degradation. The galvanization process applies a protective zinc coating to the steel surface, creating a barrier that significantly extends the material’s service life. Available in hot-dip galvanized, electro-galvanized, pre-galvanized, and post-galvanized variants, this steel type is particularly suited for outdoor applications, industrial environments, and areas exposed to humidity or aggressive substances. Galvanized steel profiles maintain excellent mechanical properties while requiring minimal maintenance over time.

Corten steel: aesthetic appeal and weathering resistance

Corten steel stands out among the types of cold rolled steel for its distinctive oxidized finish and self-protecting properties. This special alloy naturally develops a stable rust patina that halts the progression of corrosion, eliminating the need for painting or protective coatings.

Key characteristics of corten steel include:

- Natural weathering resistance that improves over time

- Warm, distinctive appearance that enhances architectural projects

- High structural strength suitable for load-bearing applications

- Reduced maintenance requirements compared to conventional steel

- Excellent performance in outdoor environments exposed to rain, sunlight, and thermal fluctuations

- Versatility for both structural and decorative applications

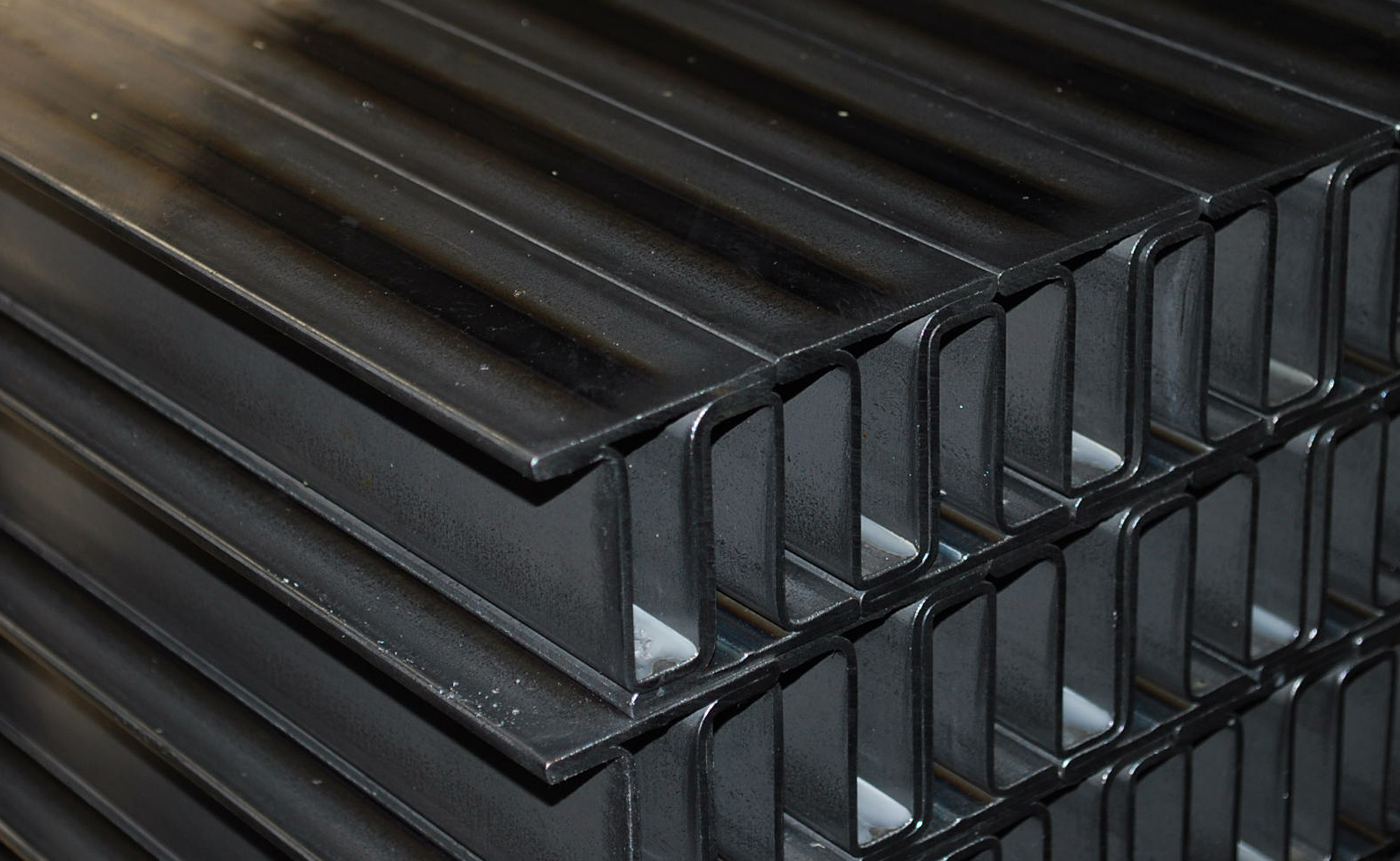

Carbon steel: versatility and cost efficiency

Carbon steel represents the most widely used category among cold rolled steel types, valued for its excellent strength-to-cost ratio and versatile mechanical properties. Available in low, medium, and high carbon variants, this material offers different levels of hardness, ductility, and tensile strength to match specific application requirements.

Low carbon steel provides superior formability and weldability, making it ideal for complex profiles and structural components. Medium and high carbon steels deliver increased hardness and wear resistance, suitable for applications subject to mechanical stress or abrasion.

While carbon steel lacks the inherent corrosion resistance of stainless or galvanized alternatives, it can be effectively protected through painting, powder coating, or galvanizing treatments. Its affordability and widespread availability make carbon steel the preferred choice for industrial machinery, automotive components, construction frameworks, and general manufacturing applications where cost efficiency is a primary consideration.

Choosing the right type of cold rolled steel

Selecting the appropriate steel type depends on several factors including the operating environment, mechanical requirements, aesthetic considerations, and budget constraints. Stainless steel excels in corrosive or hygienic environments.

Galvanized steel offers cost-effective durability for outdoor use. Corten provides unique visual appeal with minimal maintenance and pickled or pre-painted options streamline downstream processing.

Beyond material properties, businesses should also consider factors such as profile complexity, required tolerances, surface finishes, and integration with other components. A qualified manufacturer with extensive experience across multiple steel types can guide businesses through this selection process, offering technical consultation and prototype development to validate material performance before full-scale production.

This collaborative approach ensures optimal material choice for each specific application, minimizing risks and maximizing return on investment.

Sika: your expert in cold rolled steel profiles

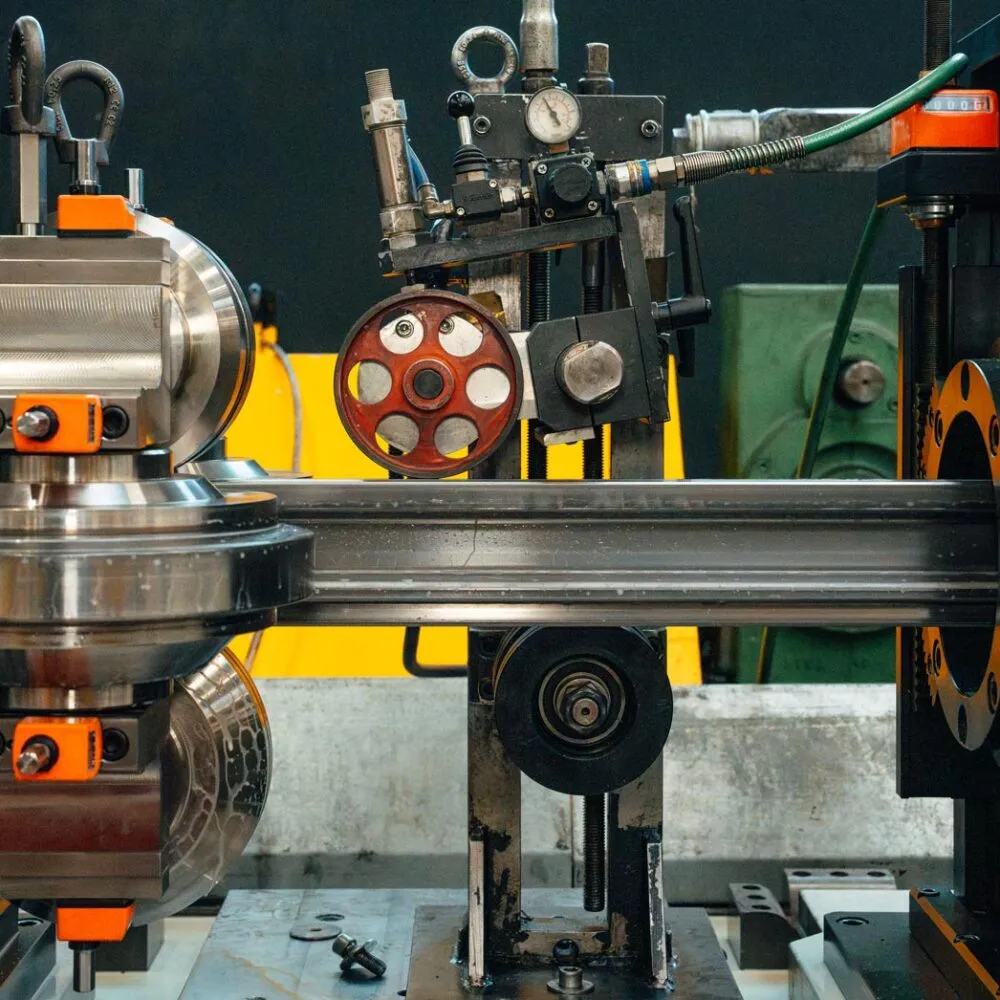

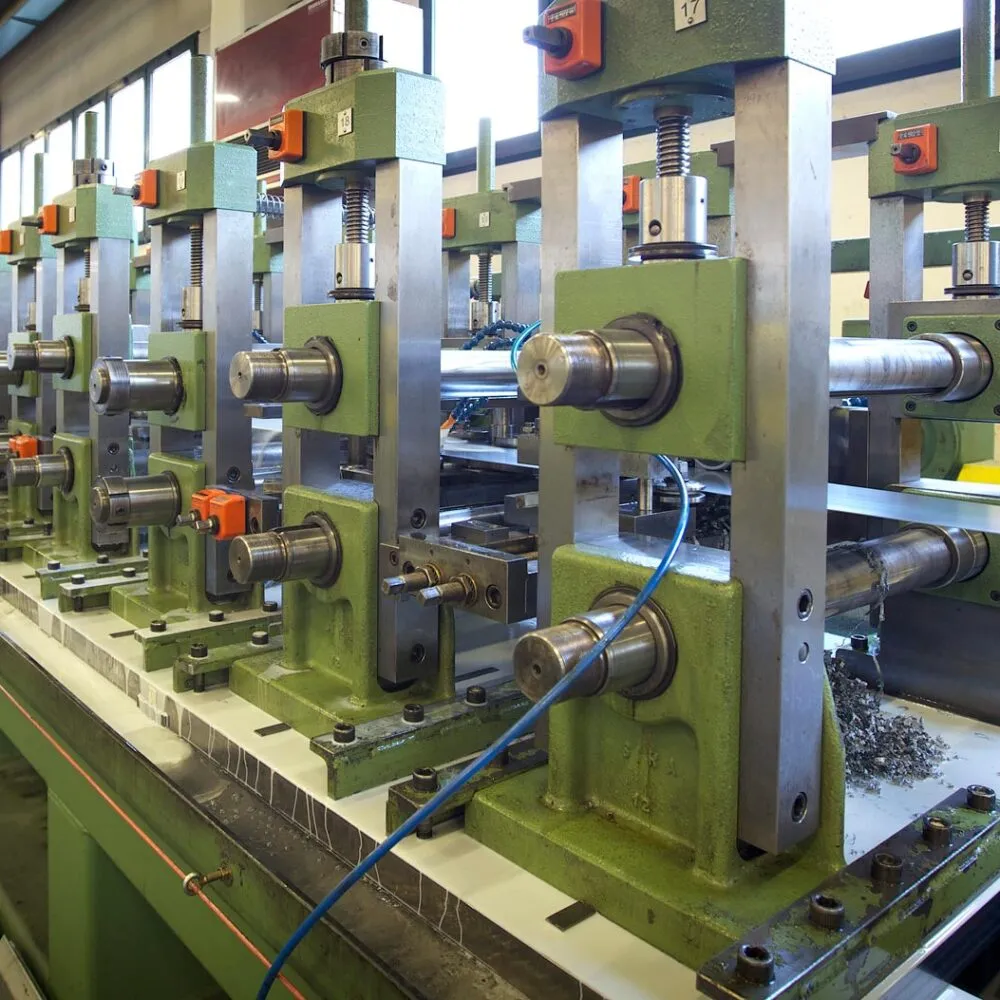

Sika is a leading manufacturer specializing in custom cold-formed profiles from all major types of cold rolled steel. With over two decades of experience serving both domestic and international markets, the company has established itself as a trusted partner for businesses seeking high-quality metal profiles engineered to precise specifications.

Sika’s advanced in-house capabilities include roll forming, cold stamping, punching, bending, calendering, and HF welding, allowing complete control over every stage of the production process. This integrated approach ensures consistent quality, shorter lead times, and the flexibility to accommodate both small batches and large-volume orders. The company transforms metal coils into precision-engineered components for a wide range of industrial sectors, including construction and infrastructure, automotive and transport, furniture and interior design and agricultural applications such as vineyard trellis structures.

Materials and certifications: quality you can trust

The company processes an extensive range of materials including stainless steel, galvanized steel, corten, carbon steel, aluminum and copper. This versatility enables Sika to meet diverse project requirements, from profiles demanding exceptional corrosion resistance to components requiring specific aesthetic finishes or mechanical properties.

Certified to ISO 9001, ISO 14001, and ISO 45001 standards, Sika demonstrates its commitment to quality management, environmental responsibility, and workplace safety.