You might be interested in

Tecnologie

What is the roll forming process: a complete guide to cold metal profiling

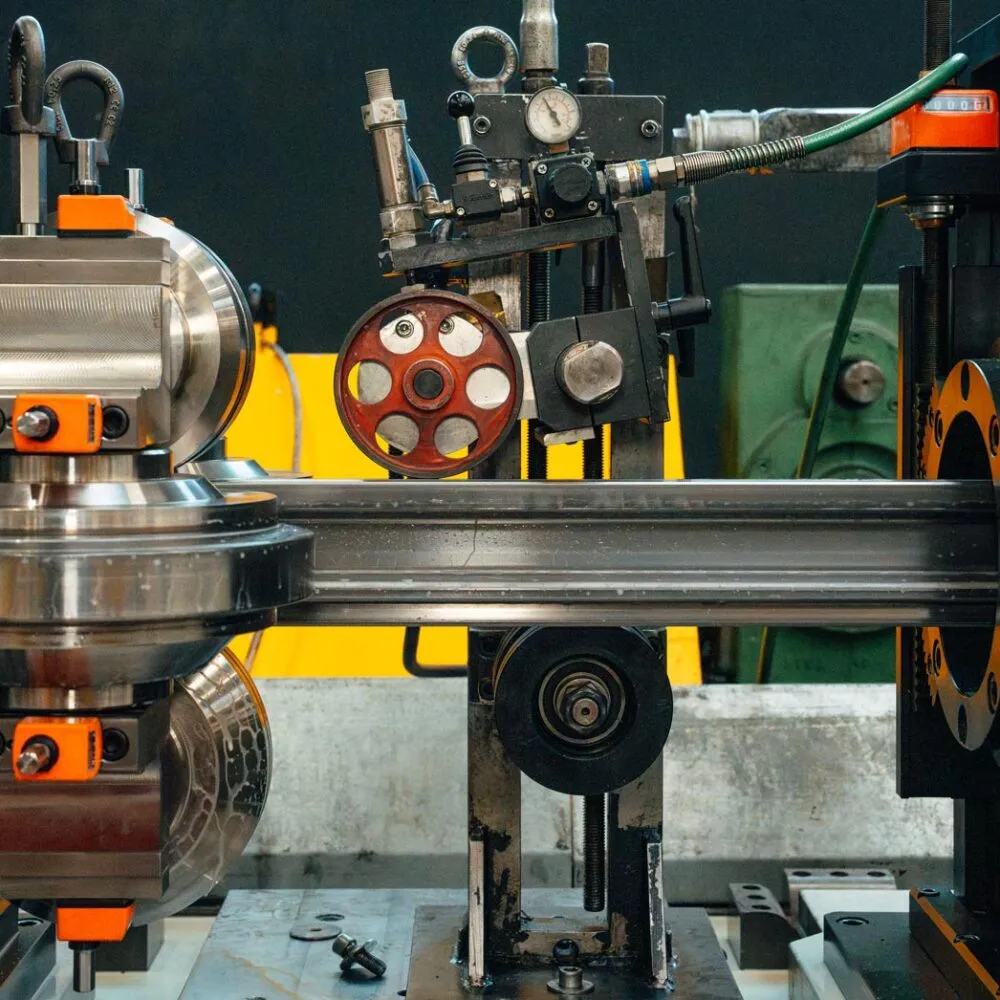

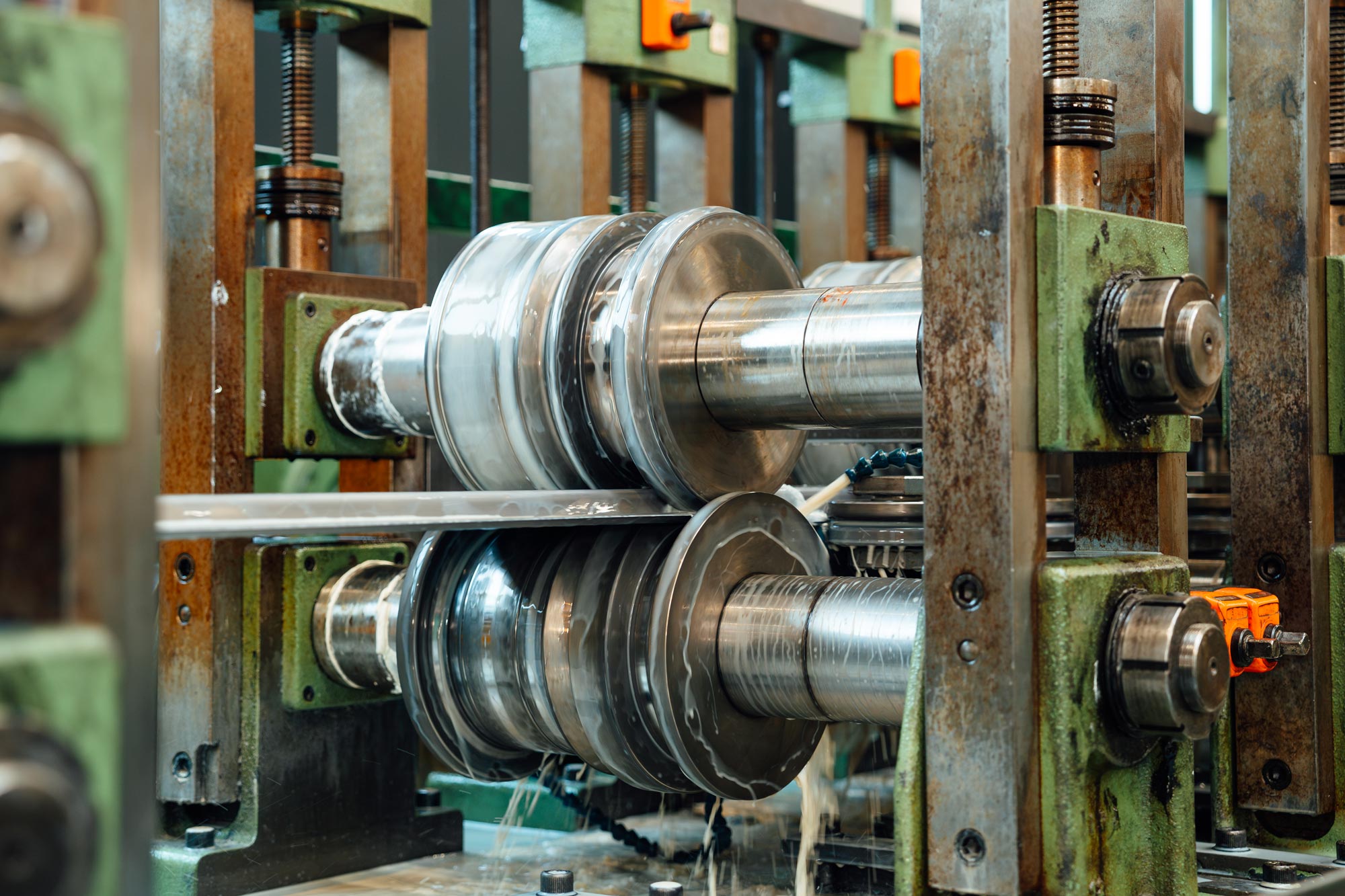

The roll forming process is a continuous metal forming technique that transforms flat metal strips into complex profiles through a series of progressive bending operations.

This cold working method, performed at room temperature without heat application, represents one of the most efficient and cost-effective solutions for producing high-volume custom metal profiles. Industries worldwide rely on the roll forming process for manufacturing structural components, architectural elements, and precision parts across construction, automotive, renewable energy, and industrial automation sectors.

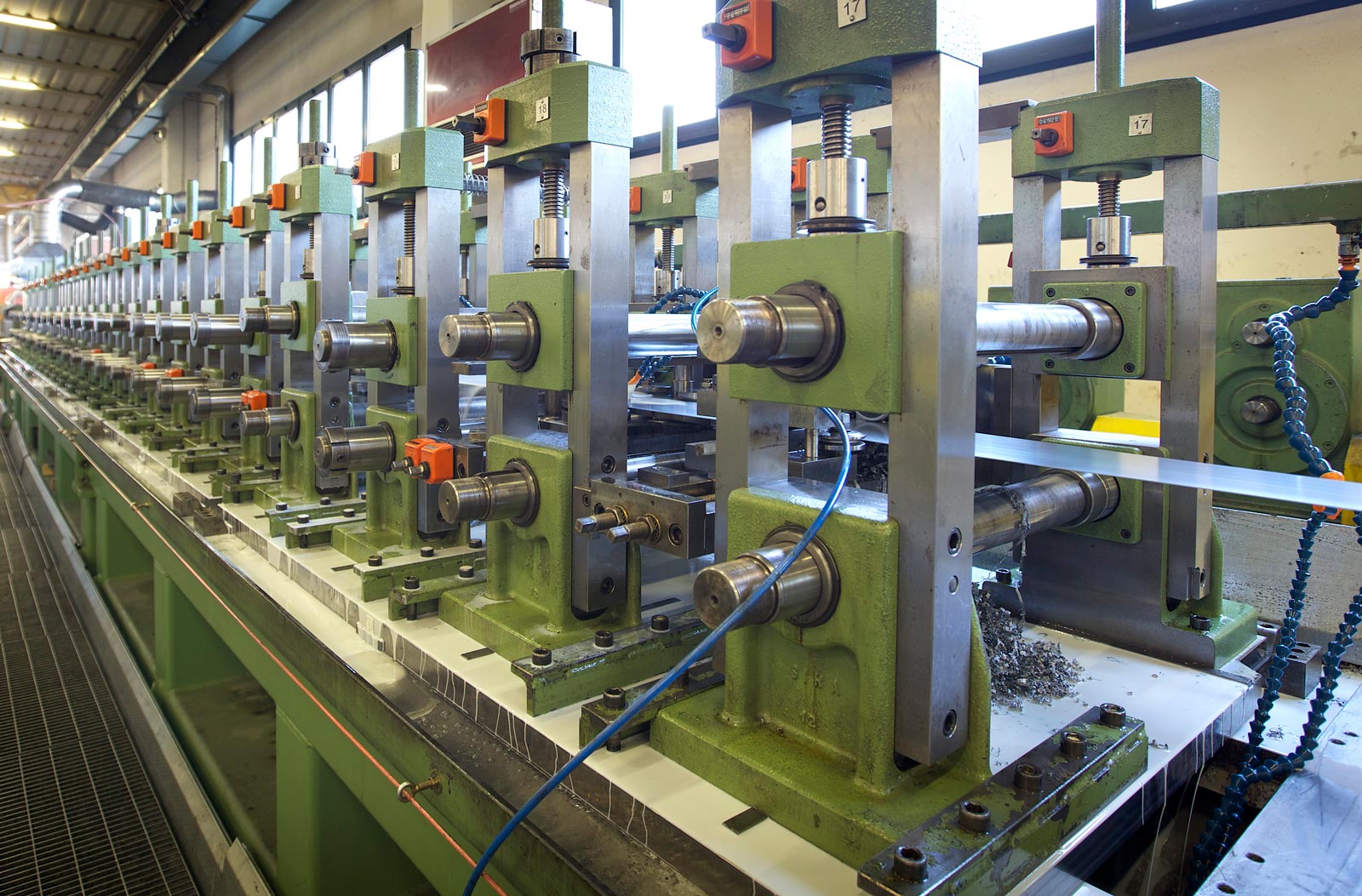

Understanding the roll forming process: how it works

The roll forming process begins with metal coils that are gradually shaped through consecutive sets of roller dies. As the metal strip passes through each rolling station, it undergoes incremental bending until achieving the final desired cross-sectional profile. This progressive forming technique, also known as cold roll profiling, operates continuously without requiring heat, preserving the metal’s mechanical properties while creating consistent, high-quality profiles. The process accommodates various materials including:

- stainless steel,

- galvanized steel,

- pickled steel,

- corten steel,

- aluminum,

- copper.

Modern roll forming systems integrate automated controls and inline secondary operations such as punching, cutting, and welding, enabling manufacturers to deliver fully finished components directly from the production line.

Key advantages of the roll forming process

The roll forming process offers significant benefits that make it the preferred choice for producing custom metal profiles in demanding industrial environments.

Precision stands as a primary advantage, with numerically controlled systems ensuring extremely tight tolerances and consistent uniformity across all profiles, critical for applications requiring exact specifications.

Cost efficiency represents another major benefit, as the continuous production system enables high-volume output in compressed timeframes, substantially reducing per-unit manufacturing costs compared to alternative forming methods. Material integrity remains preserved throughout the cold working process, with many metals actually experiencing enhanced strength characteristics without compromising ductility.

The versatility of roll forming allows manufacturers to produce profiles of varying complexity, from simple channels to intricate multi-bend sections, while maintaining production efficiency. Additionally, the process supports inline integration of secondary operations, eliminating the need for separate manufacturing steps and reducing lead times for custom components.

Applications and materials in the roll forming process

The roll forming process serves diverse industrial sectors, delivering tailored metal profile solutions that meet specific project requirements.

Common applications include:

- Construction and Infrastructure: structural framing systems, prefabricated building components, metal roofing and siding panels, ventilated facade systems, and load-bearing profiles for commercial and residential structures

- Automotive and Transportation: body reinforcement components, chassis elements, door frames, trim parts, and specialized profiles for vehicle assembly requiring high precision and consistent quality

- Renewable Energy: solar panel mounting structures, wind turbine components, and support systems designed to withstand environmental stresses while maintaining structural integrity

- Industrial Equipment: machine frames, conveyor systems, racking structures, forklift components, and automation equipment requiring robust custom profiles

- Architecture and Design: window and door frames, glass railing systems, shower enclosures, architectural lighting fixtures, and decorative metal elements combining functionality with aesthetic appeal

- Agriculture: vineyard trellis posts, greenhouse structures, fencing systems, and specialized agricultural equipment components manufactured from corrosion-resistant materials like galvanized and corten steel.

Material selection in the roll forming process

Material choice significantly impacts the performance and longevity of roll-formed profiles.

Galvanized steel profiles provide excellent corrosion resistance for outdoor applications, while stainless steel offers superior durability in corrosive environments and maintains aesthetic appeal without protective coatings.

Carbon steel and pickled steel deliver high strength-to-weight ratios for structural applications, whereas corten steel develops a protective rust patina ideal for architectural and agricultural uses.

Aluminum profiles provide lightweight solutions with natural corrosion resistance, particularly valued in transportation and architectural applications.

Copper profiles serve specialized electrical and decorative applications requiring superior conductivity and distinctive appearance. Advanced materials like Magnelis extend service life in harsh environments through enhanced zinc-aluminum-magnesium coatings.

Selecting the right roll forming partner

Choosing an experienced roll forming manufacturer requires evaluating several critical factors. Technical expertise in profile design ensures optimal geometry for your specific application, while production capacity determines ability to meet volume requirements and delivery schedules. Material knowledge helps select the appropriate alloys and treatments for your operating environment, and secondary processing capabilities reduce supply chain complexity by consolidating operations. Quality certifications provide assurance of consistent manufacturing standards, while customization flexibility allows adaptation to unique project specifications.

Sika’s experience and quality in roll forming process

Sika Profili stands as a trusted partner in custom roll-formed metal profiles, combining decades of metalworking experience with cutting-edge technology. With ISO 9001, ISO 14001, and ISO 45001 certifications, Sika guarantees excellence in quality, environmental responsibility, and safety. Our advanced cold roll forming systems, integrated with punching, stamping, calendering, and HF welding capabilities, enable us to deliver complete, ready-to-install solutions.

From construction and automotive to renewable energy and agriculture, Sika transforms metal coils into high-performance components tailored to meet the most demanding project challenges. Contact us for a custom quote and discover how our roll forming expertise can bring your project to life.