You might be interested in

Tecnologie

Hot vs cold rolling process: understanding the key differences in metal forming

The hot vs cold rolling process comparison represents a fundamental decision in metal manufacturing that directly impacts product performance, cost, and application suitability. Both rolling methods transform metal through progressive deformation using rotating cylinders, yet they operate under vastly different temperature conditions that produce distinct material characteristics. Hot rolling occurs at temperatures exceeding the metal’s recrystallization point, typically above 1700°F (926°C), allowing for easier shaping and cost-effective production of large structural components.

Cold rolling, performed at or near room temperature, delivers superior dimensional accuracy, enhanced surface finish, and increased material strength through strain hardening.

Understanding these differences enables manufacturers to select the optimal process for their specific application requirements, whether prioritizing structural capability, precision engineering, or aesthetic appeal.

Hot rolling process: high-temperature metal forming

The hot rolling process begins with heating metal billets to temperatures significantly above their recrystallization point, generally exceeding 1700°F (926°C). At these elevated temperatures, the metal becomes highly malleable, allowing it to be easily shaped and formed through successive passes between rotating rollers.

The heated material is first compressed into a large roll, then progressively passed through multiple roller stations that reduce thickness and achieve desired dimensions.

For sheet metal production, the processed steel is wound into coiled rolls and allowed to cool gradually at ambient temperature. This controlled cooling process normalizes the metal’s crystalline structure, eliminating internal stresses that could compromise structural integrity. The hot rolling method excels at producing large-scale products including structural beams, railroad rails, sheet metal, construction steel bars, and heavy-gauge plates where precise tolerances are less critical than overall strength and formability. The process offers significant manufacturing advantages: lower production costs due to reduced processing requirements, better workability from the elevated temperatures, and faster production rates ideal for high-volume operations. However, hot rolled steel exhibits characteristic surface scaling, slightly rounded edges, and less precise dimensional control due to non-uniform shrinkage during cooling.

Cold rolling process: precision metal forming at room temperature

Cold rolling, despite its name, refers to metal forming performed at or near room temperature, specifically below the material’s recrystallization temperature. This process typically begins with hot rolled steel as the starting material, which then undergoes additional processing to achieve enhanced properties and tighter specifications. The metal sheet or strip coil passes through high-pressure rollers that compress the material just below its ultimate tensile strength, permanently altering its crystalline structure through mechanical deformation rather than heat. This strain hardening phenomenon increases the steel’s strength by approximately 20 percent while simultaneously improving hardness, yield strength, and tensile strength. Cold rolling can reduce material thickness by up to 80 percent depending on end-product requirements, with dimensional precision and surface finish quality 5 to 10 times superior to hot rolling. The process produces steel with a smooth, polished surface exhibiting a matte or satin-like appearance, ideal for applications requiring visual appeal and consistent aesthetics. After passing through the cold rolls, the material often undergoes annealing at controlled temperatures to reduce brittleness and restore ductility, enabling further forming operations. Cold rolled steel demonstrates various temper grades based on processing intensity: quarter-hard steel can bend 180 degrees without breaking, half-hard steel achieves 90-degree bends, while full-hard steel is limited to 45-degree angles before failure.

Key differences between hot vs cold rolling process

The fundamental distinctions between hot and cold rolling extend beyond temperature to encompass multiple performance characteristics and manufacturing considerations:

- Operating Temperature: hot rolling occurs above recrystallization temperature (typically 1700°F+), while cold rolling operates at or near room temperature, fundamentally changing how metal responds to deformation

- Material Properties: cold rolling increases hardness and strength by up to 20% through strain hardening, whereas hot rolling produces normalized steel free from work-hardening stresses but with lower baseline strength

- Dimensional Accuracy: cold rolling achieves extremely tight tolerances and precise dimensions with minimal variation, while hot rolled steel exhibits less dimensional control due to thermal contraction during cooling

- Surface Finish: cold rolled steel features smooth, clean, aesthetically pleasing surfaces without scale or oxidation, compared to hot rolled steel’s characteristic rough texture with surface scaling and slight irregularities

- Production Cost: hot rolling proves more cost-effective due to simplified processing, lower energy requirements, and faster production rates, while cold rolling commands premium pricing reflecting additional processing steps and extended production time

- Internal stress: hot rolled steel remains essentially stress-free after gradual cooling, whereas cold rolling introduces significant internal stresses requiring stress relief before cutting, grinding, or welding to prevent warping

- Formability: hot rolled steel offers superior formability and easier manipulation for large structural shapes, while cold rolled steel requires careful handling due to increased brittleness but enables complex precision geometries.

Material selection: hot vs cold rolling process for different applications

Selecting between hot and cold rolling depends entirely on specific project requirements, balancing performance needs against cost considerations.

Hot rolled steel applications

Hot rolled steel dominates applications requiring large structural components, high-volume production, and cost efficiency where surface appearance and precise tolerances are secondary concerns. Construction projects utilize hot rolled beams, columns, and reinforcing bars for building frameworks and infrastructure. Railroad manufacturing relies on hot rolled steel for tracks and rail components requiring toughness and weldability. Automotive industries employ hot rolled steel for chassis frames, suspension components, and structural reinforcements. Agricultural equipment, heavy machinery frames, door frames, highway signs, and general fabrication work all benefit from hot rolling’s cost-effectiveness and structural capability.

Cold rolled steel applications

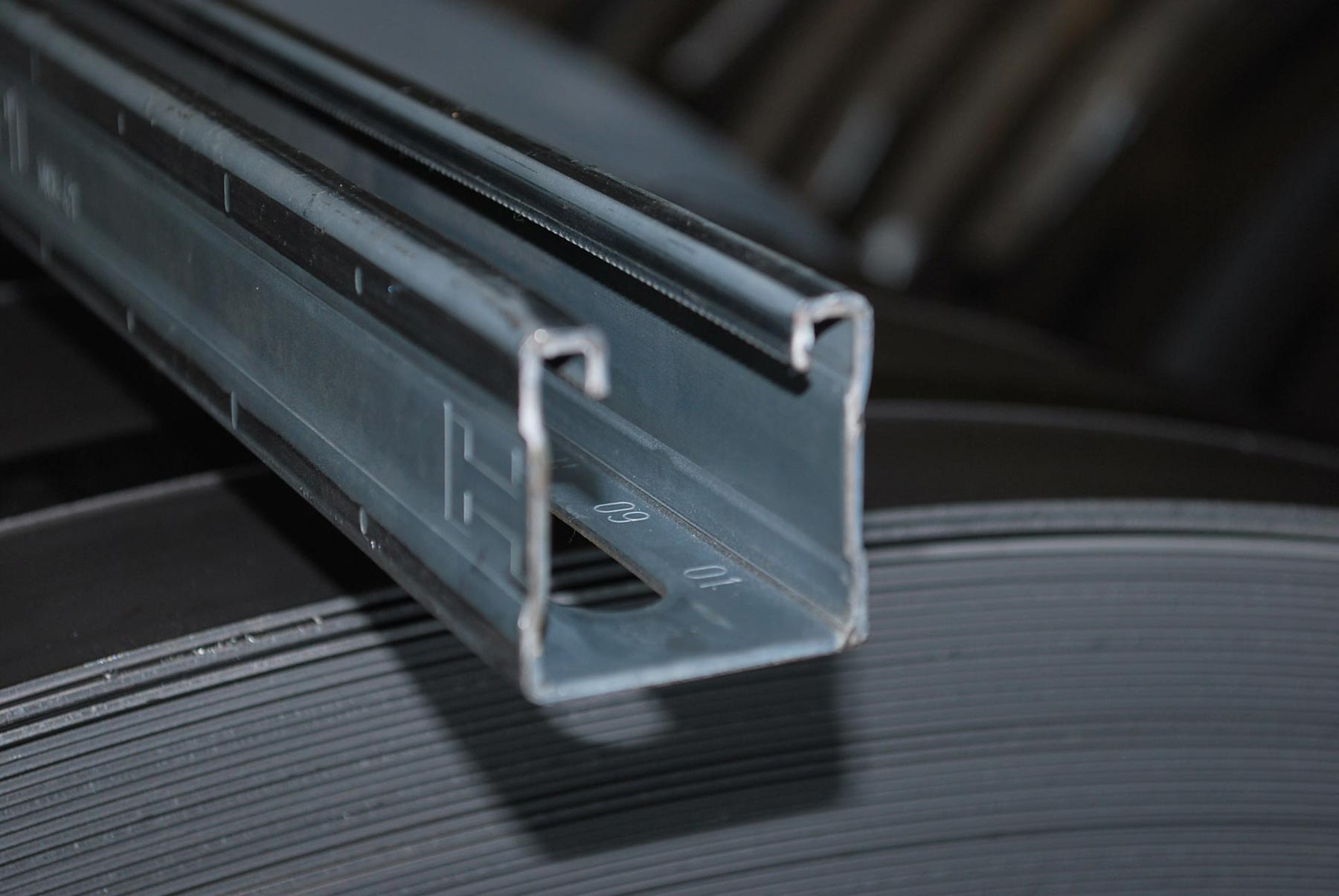

Cold rolled steel serves applications demanding superior surface quality, dimensional precision, and enhanced mechanical properties. Automotive manufacturers use cold rolled steel for body panels, trim components, and precision parts requiring consistent appearance and tight tolerances. Appliance manufacturing depends on cold rolled steel for washing machines, refrigerators, and other consumer products where aesthetics matter. Furniture production values the smooth finish and precise dimensions for metal desking, shelving, and decorative elements. Precision engineering applications including electronics enclosures, small mechanical components, and instrumentation parts require cold rolling’s accuracy. When combined with subsequent profiling processes like cold roll forming, cold rolled steel becomes the ideal starting material for custom metal profiles used across construction, renewable energy, industrial automation, and architectural applications.

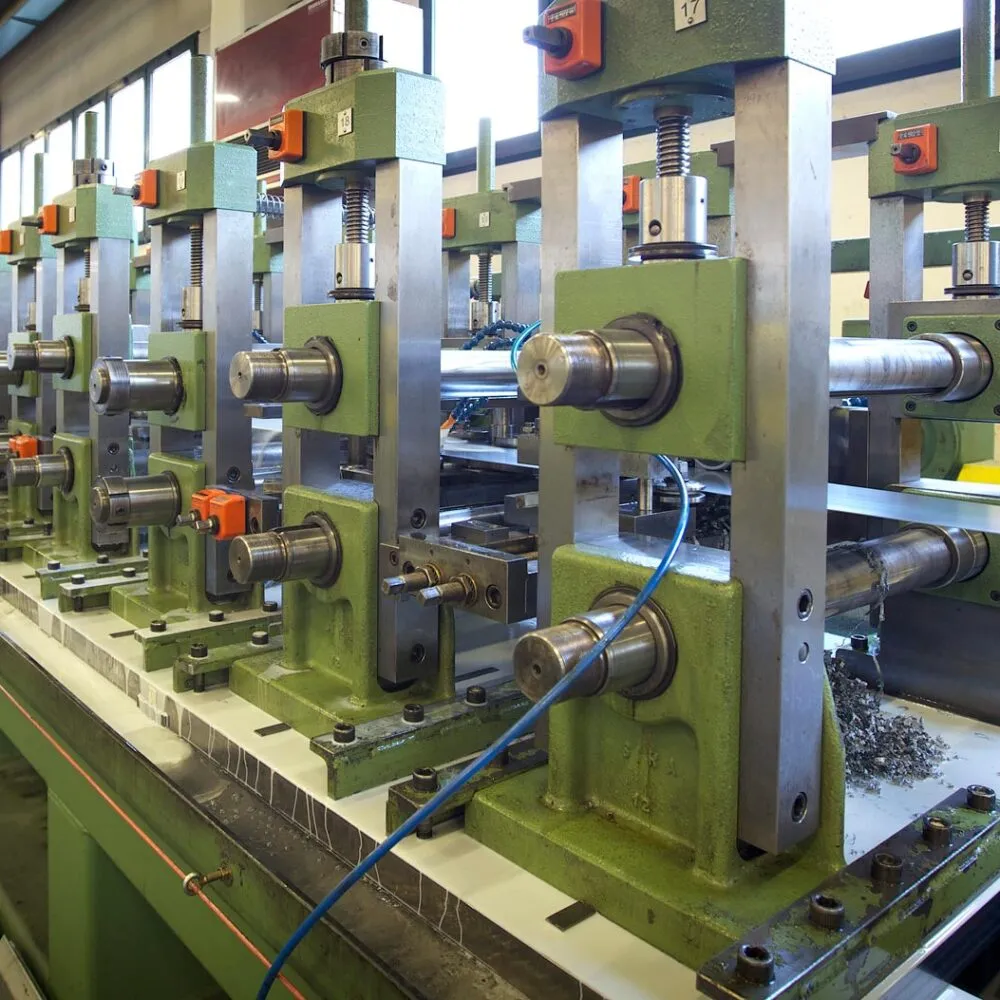

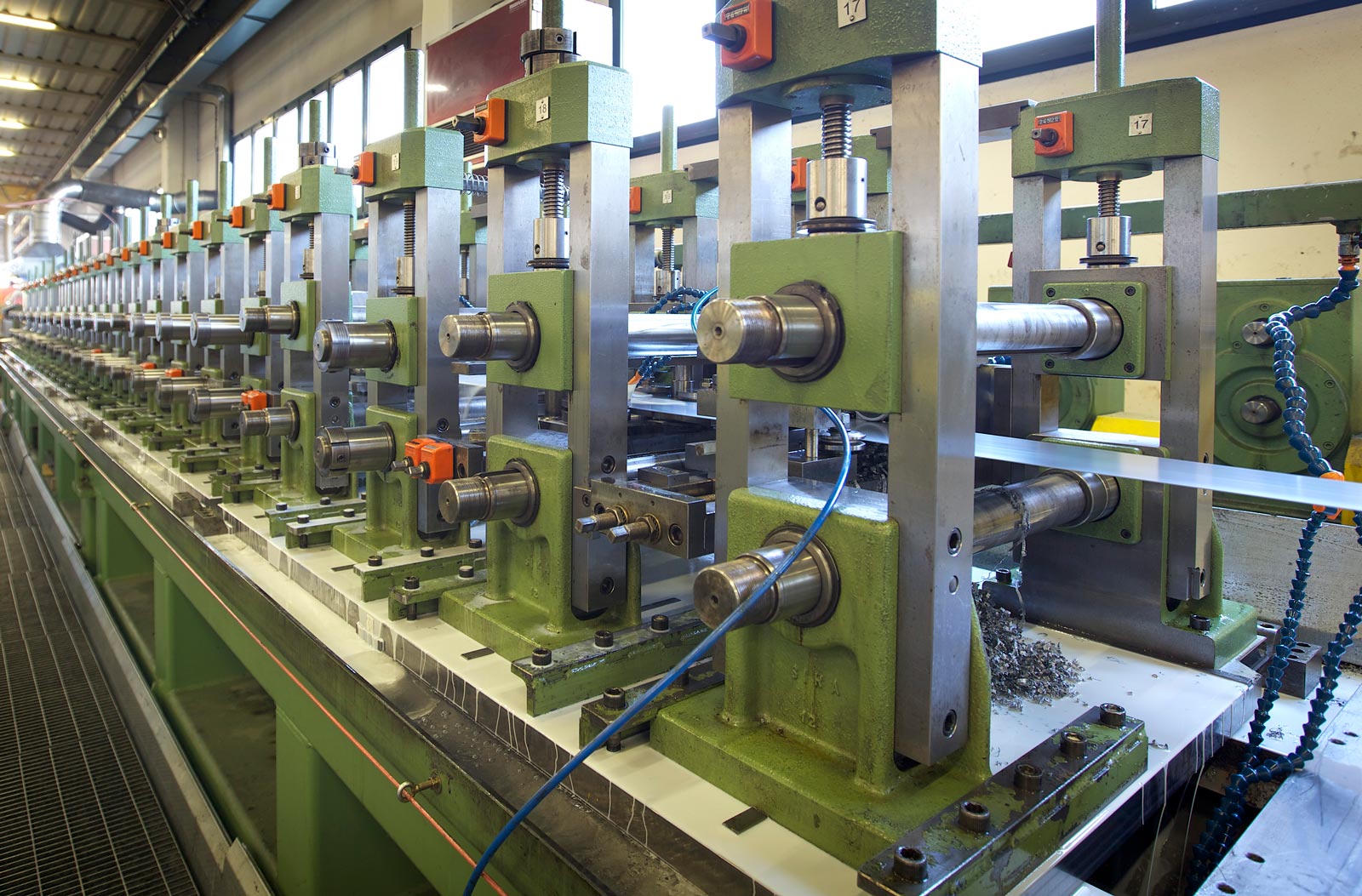

Cold roll forming: the next evolution in metal profile manufacturing

While understanding the hot vs cold rolling process provides essential foundational knowledge, many advanced applications require additional processing beyond basic sheet production. Cold roll forming represents a specialized technique that takes cold rolled steel strips and progressively shapes them into complex custom profiles through consecutive roller stations. This process, performed entirely at room temperature, preserves and even enhances the material properties achieved during initial cold rolling while creating three-dimensional profiles with precise cross-sectional geometries. Sika Profili specializes in this advanced cold roll forming technology, transforming cold rolled coils of stainless steel, galvanized steel, pickled steel, aluminum, and other materials into custom-designed profiles for demanding industrial applications. The company’s integrated manufacturing approach combines cold roll forming with secondary operations including automated punching, cold stamping, profile calendering, and HF welding, delivering complete, ready-to-install components that eliminate additional processing steps.

Choosing the right partner for metal rolling and profiling solutions

Understanding the hot vs cold rolling process distinctions enables informed material selection, but successful project execution requires partnering with experienced manufacturers who master both technologies. Companies must evaluate multiple factors when selecting a metal processing partner: technical expertise in material properties and process optimization, production capacity to meet volume and delivery requirements, quality certifications ensuring consistent manufacturing standards, and integrated capabilities that reduce supply chain complexity. Sika Profili combines comprehensive metalworking knowledge with state-of-the-art cold roll forming technology to deliver custom metal profiles that exceed industry standards.

Sika’s experience and quality in cold rolling process

With ISO 9001, ISO 14001, and ISO 45001 certifications, Sika guarantees excellence in quality management, environmental responsibility, and occupational safety. Our advanced production facilities process materials from 0.4mm to 4mm thickness, with strip widths up to 550mm and profile lengths from 200mm to 13 meters, accommodating diverse project specifications. From initial design consultation through final component delivery, Sika’s engineering team works collaboratively with clients to optimize profile geometry, select appropriate materials, and integrate secondary operations, transforming cold rolled metal coils into high-performance custom profiles for construction, automotive, renewable energy, agriculture, and industrial automation applications worldwide.