You might be interested in

The advantages of cold roll forming for special profiles

Why choose cold roll forming for special profiles: all the benefits

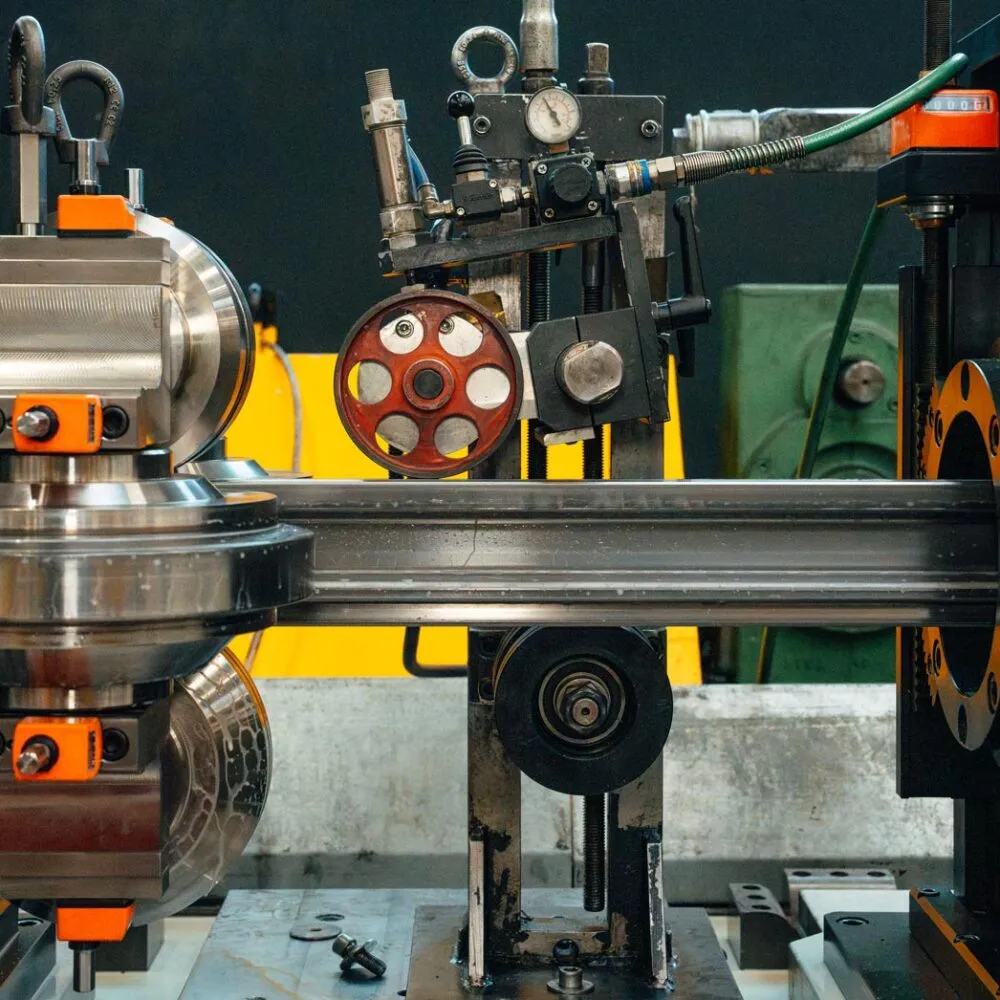

Cold roll forming is an advanced and highly efficient technology in the metalworking industry. This production process enables the creation of special profiles with optimal technical and structural properties, while significantly reducing operational costs and processing time. Let’s explore the main benefits of cold roll forming and why it is a strategic choice for numerous industrial applications.

1. Optimized production process

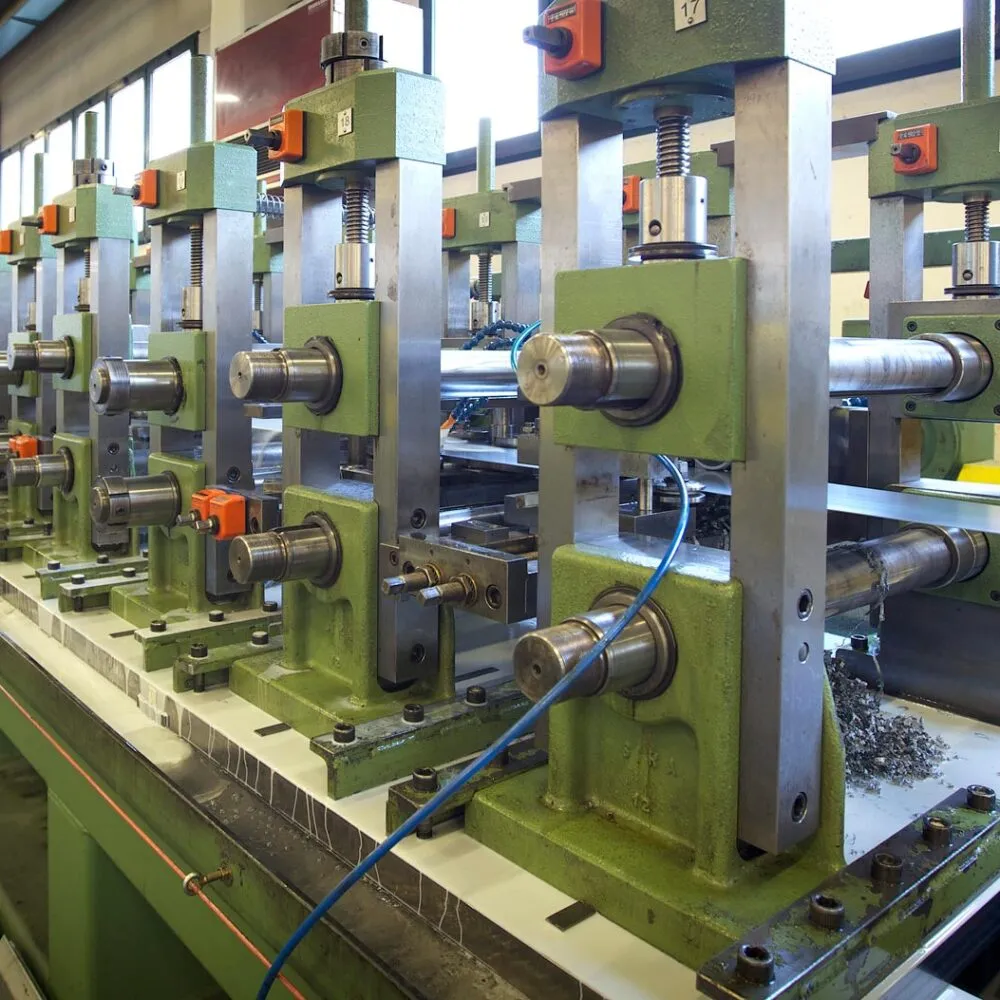

Cold roll forming allows the production of a finished profile in a single manufacturing step. Thanks to the flexibility of roll forming lines, multiple operations such as drilling, punching, embossing, and marking can be integrated directly in-line, without the need for additional processes. This results in a significant reduction in production time and a streamlined supply chain.

2. Higher precision and repeatability

One of the main advantages of cold roll forming is its ability to ensure extremely precise and consistent dimensional tolerances throughout the entire production run. This feature is especially valuable in industries such as automotive, construction, and mechanical engineering, where dimensional accuracy is a critical requirement.

3. Reduced logistics costs and streamlined supply chain

Since custom profiles are manufactured directly in-line with all integrated processing steps, the need for sourcing separate components is significantly reduced. This leads to fewer suppliers involved, less administrative complexity, and substantial optimization of transportation and storage costs.

4. Lower environmental impact

Reducing the number of production steps not only shortens processing times but also minimizes energy consumption and significantly cuts material waste. Cold roll forming is an extremely energy-efficient process, making it an ideal solution for lowering the environmental impact of metal profile manufacturing.

5. Optimized production space

Thanks to its ability to consolidate multiple processing stages into a single compact line, cold roll forming allows manufacturers to save valuable floor space. This is particularly beneficial for companies operating in confined environments or seeking to optimize internal layout and workflow efficiency.

6. Advanced customization

Roll forming technology enables the production of custom profiles with complex geometries and specific characteristics as requested by the client. This flexibility makes it possible to tailor the final product to design specifications, avoiding costly post-processing or modifications.

7. Durability and strength

Profiles manufactured through cold roll forming stand out for their exceptional mechanical strength and long-term durability. The use of high-quality raw materials, combined with a process that enhances structural properties, ensures that special profiles can withstand both mechanical stress and harsh environmental conditions.

Conclusion

Cold roll forming of special profiles is a versatile and efficient solution for a wide range of industrial sectors. Its advantages in terms of cost reduction, time optimization, and product quality make it a key technology for those seeking high performance and sustainability. Choosing this process means embracing a modern manufacturing approach capable of meeting market demands with precision and efficiency.

Contact us to discover how Sika can support your project with high-quality custom profiles and tailored solutions.

Fill out the form to receive information or a free quote with no obligation.