You might be interested in

News

Benefits of cold rolled steel: why choose cold rolled over hot rolled metal

The benefits of cold rolled steel make it the preferred choice for applications requiring superior dimensional accuracy, enhanced surface finish, and increased mechanical strength. Unlike hot rolled steel, which is processed at elevated temperatures, cold rolled steel undergoes additional processing at room temperature that fundamentally transforms its properties through strain hardening. This room-temperature forming process produces steel with up to 20% greater strength, significantly improved surface quality, and dimensional tolerances 5 to 10 times tighter than hot rolled alternatives.

Understanding the specific advantages of cold rolled steel enables manufacturers and engineers to make informed material selections that optimize product performance, reduce downstream processing costs, and ensure long-term reliability in demanding operational environments.

Superior dimensional accuracy and tight tolerances thanks to cold rolled steel

Among the most significant benefits of cold rolled steel is its exceptional dimensional precision and ability to maintain extremely tight tolerances throughout production. The cold rolling process occurs at room temperature, eliminating the thermal expansion and contraction variables inherent in hot rolling that cause unpredictable dimensional changes during cooling.

This temperature stability enables manufacturers to achieve dimensional accuracy 5 to 10 times superior to hot rolled steel, with consistent thickness uniformity across entire sheet lengths and coil widths. Cold rolled steel maintains precise measurements that remain stable through subsequent fabrication operations, reducing the need for additional machining or correction processes.

This dimensional consistency proves critical in applications requiring exact fitment, such as automotive body panels that must align perfectly, appliance components with precise mounting specifications, electronics enclosures demanding accurate hole patterns, and architectural elements requiring seamless assembly.

The predictable geometry of cold rolled steel simplifies design engineering, reduces assembly time, and minimizes material waste from out-of-specification parts. For manufacturers producing custom metal profiles through cold roll forming, starting with cold rolled steel coils ensures the final profiles maintain precise cross-sectional dimensions essential for modular systems, structural assemblies, and technical applications where tolerances directly impact functionality and safety.

Enhanced surface finish and aesthetic appeal

The benefits of cold rolled steel extend prominently to surface quality, delivering smooth, clean finishes that eliminate the need for extensive surface preparation in many applications. Cold rolling produces steel with a polished appearance exhibiting matte or satin-like characteristics, completely free from the mill scale, surface oxidation, and roughness typical of hot rolled steel.

This superior surface finish results from the controlled mechanical deformation at room temperature, which compresses and smooths the material without introducing heat-related surface defects. The clean, consistent surface of cold rolled steel accepts paint, powder coating, and other finishing treatments more uniformly, ensuring better adhesion and longer-lasting protective coatings. Applications prioritizing visual appeal benefit substantially from cold rolled steel’s aesthetic qualities that meet demanding appearance standards without secondary finishing operations.

The absence of surface scale also prevents contamination in sensitive applications such as food processing equipment and medical device components. When cold rolled steel serves as the starting material for custom profile manufacturing, the resulting formed sections maintain smooth internal and external surfaces throughout complex geometries, delivering professional-grade components suitable for visible installations and high-end applications where surface quality directly impacts perceived product value.

Increased strength and improved mechanical properties

Cold rolled steel delivers significant mechanical property enhancements compared to hot rolled alternatives, representing crucial benefits of cold rolled steel for structural and load-bearing applications. The cold rolling process introduces strain hardening, a work-hardening phenomenon where mechanical deformation at room temperature permanently alters the metal’s crystalline structure, increasing dislocation density and grain boundary interactions.

This transformation increases material hardness by approximately 20%, while simultaneously improving yield strength, tensile strength, and resistance to deformation under stress. The enhanced mechanical properties enable engineers to specify thinner gauge materials that achieve equivalent or superior performance compared to thicker hot rolled sections, reducing overall material consumption and component weight without compromising structural integrity. Applications benefit from improved formability characteristics that allow cold rolled steel to be manipulated into complex shapes while maintaining structural coherence, essential for precision-formed components in automotive manufacturing, industrial equipment, and architectural systems.

The increased hardness proves advantageous for applications involving wear resistance, impact tolerance, and long-term dimensional stability under cyclic loading. However, these strength gains come with increased brittleness, requiring careful consideration of forming operations and potential stress relief treatments before welding, cutting, or machining operations that might otherwise cause warping or cracking in the finished component.

Key advantages of cold rolled steel in manufacturing applications

The comprehensive benefits of cold rolled steel establish it as the optimal material choice across diverse industrial sectors requiring precision, quality, and performance:

- Consistency and repeatability: cold rolled steel exhibits uniform properties throughout production runs, ensuring batch-to-batch consistency critical for high-volume manufacturing where every component must meet identical specifications without variation.

- Reduced secondary processing: the superior surface finish and dimensional accuracy eliminate or minimize grinding, polishing, and machining operations, reducing production time, labor costs, and material waste while accelerating time-to-market.

- Better material utilization: precise thickness control and consistent dimensions enable optimized nesting patterns and cutting layouts that maximize material yield, particularly important in sheet metal fabrication and profile production where material costs significantly impact project economics.

- Enhanced corrosion resistance base: the clean, scale-free surface of cold rolled steel provides an ideal substrate for protective coatings, galvanizing, and other corrosion-prevention treatments that adhere more effectively and last longer than treatments applied to rough hot rolled surfaces.

- Improved weldability control: while cold rolled steel requires stress relief before welding to prevent warping, the consistent material properties and clean surfaces enable more predictable welding outcomes with uniform heat-affected zones and reliable joint strength.

- Versatile forming capabilities: cold rolled steel accommodates various secondary forming processes including bending, stamping, deep drawing, and roll forming, making it ideal for producing complex three-dimensional components from flat sheet stock.

Selecting cold rolled steel for your manufacturing needs: partner with Sika Profili

Recognizing the benefits of cold rolled steel represents only the first step in material selection; successful implementation requires partnering with experienced manufacturers who understand how to optimize these advantages for specific applications.

Material selection must consider the complete manufacturing process, including forming operations, joining methods, surface treatments, and end-use requirements that influence whether cold rolled steel’s premium properties justify its higher cost compared to hot rolled alternatives. Applications requiring precision fitment, visible surfaces, weight optimization, or demanding mechanical performance clearly benefit from cold rolled steel, while purely structural applications with relaxed tolerances may find hot rolled steel more economical.

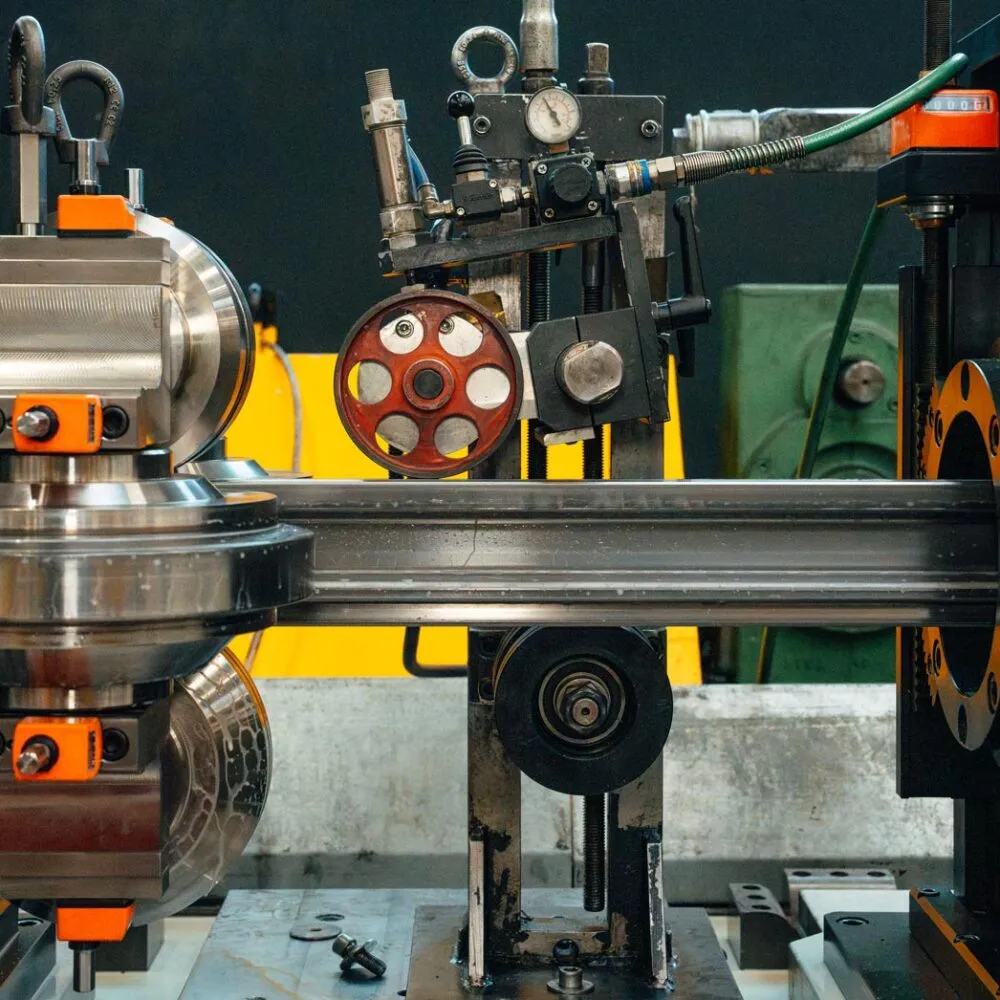

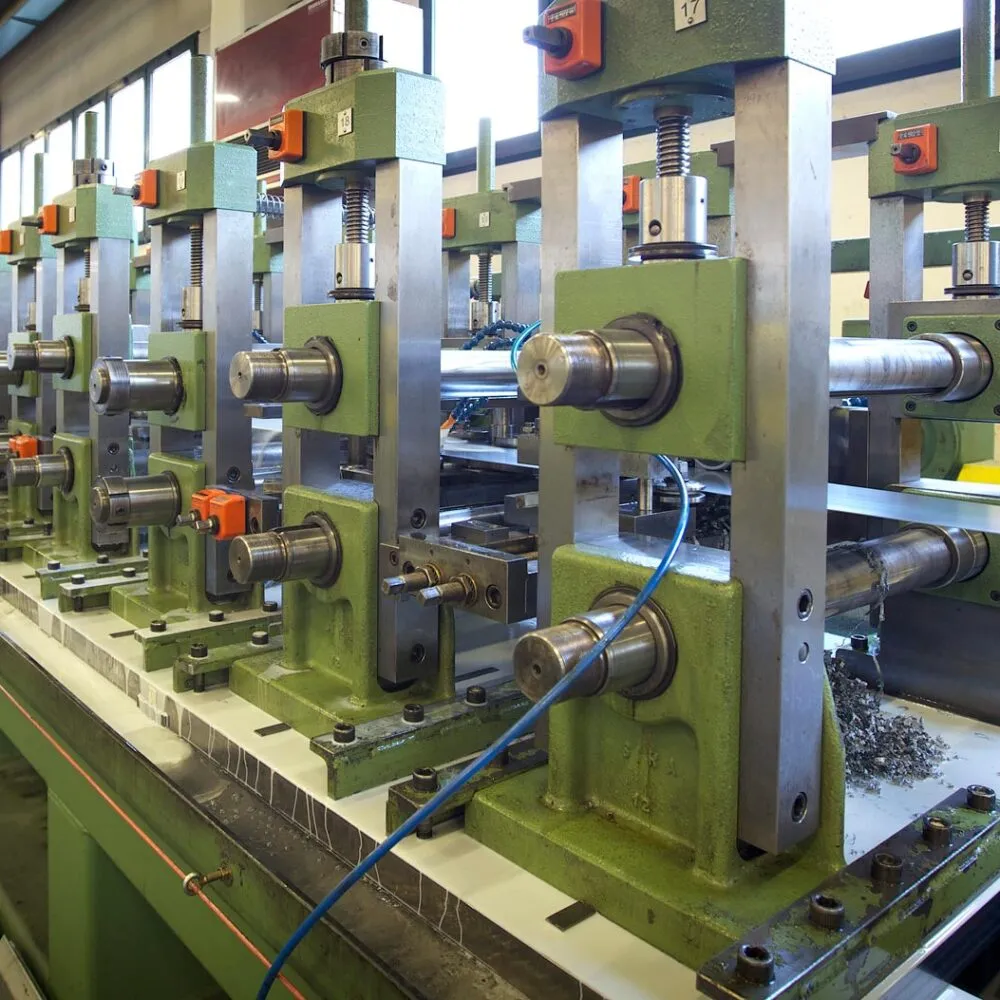

Sika Profili specializes in transforming cold rolled steel coils into custom-designed metal profiles that leverage every advantage of the material through advanced cold roll forming technology. Our integrated manufacturing capabilities process cold rolled stainless steel, galvanized steel, pickled steel, aluminum, and other materials with thicknesses from 0.4mm to 4mm, creating profiles with precise cross-sections, superior surface quality, and enhanced mechanical properties.

Sika’s experience and quality in cold rolled steel

With ISO 9001, ISO 14001, and ISO 45001 certifications, Sika guarantees consistent quality, environmental responsibility, and operational safety throughout production. Our engineering team collaborates with clients from initial design consultation through final component delivery, optimizing profile geometry to maximize the benefits of cold rolled steel while integrating secondary operations including punching, stamping, bending, and welding.

Whether your application demands architectural profiles for visible installations, structural components requiring precise tolerances, or specialized sections for industrial equipment, Sika Profili delivers custom cold rolled steel profiles that transform engineering requirements into high-performance reality. Contact us today for a consultation and discover how our cold roll forming expertise can elevate your project with the proven benefits of cold rolled steel.