Custom metal profiles

Cold-Rolled custom steel and aluminum profiles

Sika metal profiles

At Sika Profili, we specialize in the production of custom-designed metal profiles through cold roll forming. Using cutting-edge technology and high-quality materials such as stainless steel, galvanized steel, pickled steel, corten, aluminum, and copper, we deliver precise and durable solutions.

We are experts in cold roll forming and cold stamping, producing custom steel profiles for a wide range of industries. As a dynamic and forward-thinking company with decades of experience, we offer advanced metalworking expertise and tailor-made profile manufacturing, ensuring robust, reliable, and customized solutions for clients worldwide.

Tailored processes

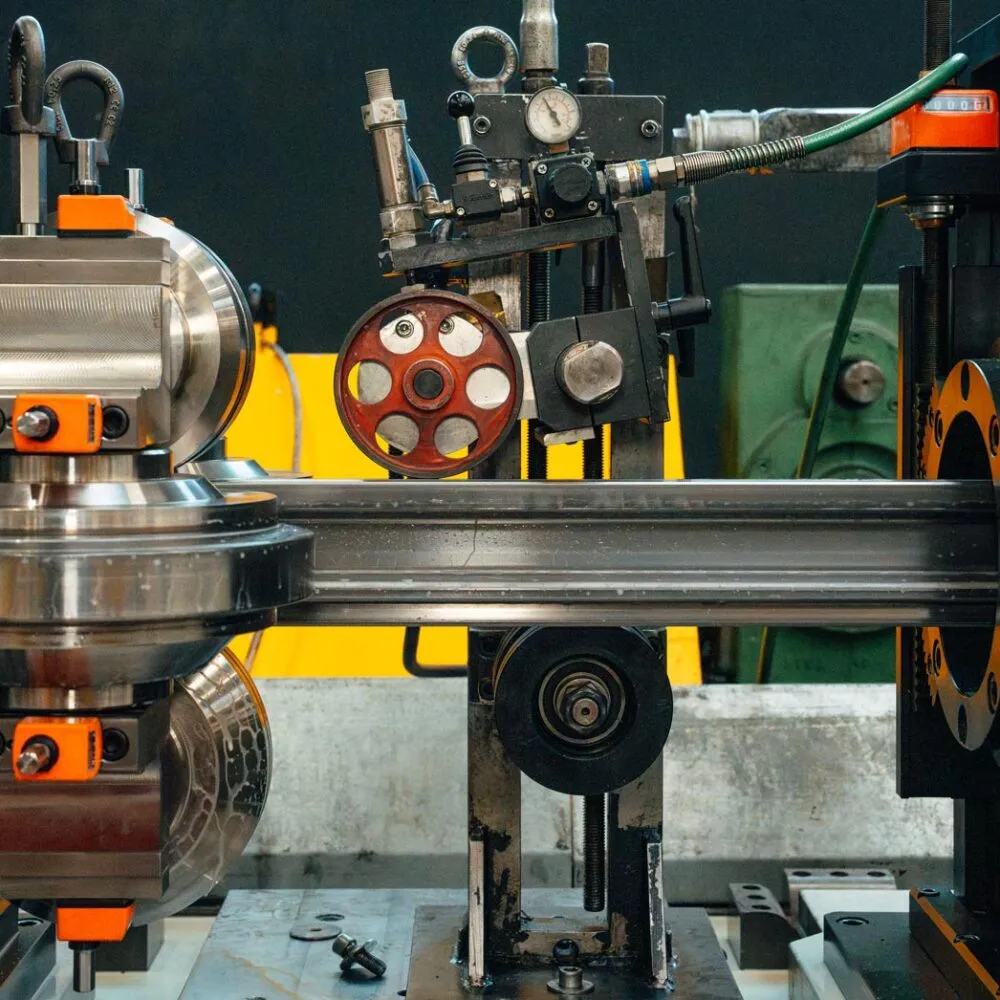

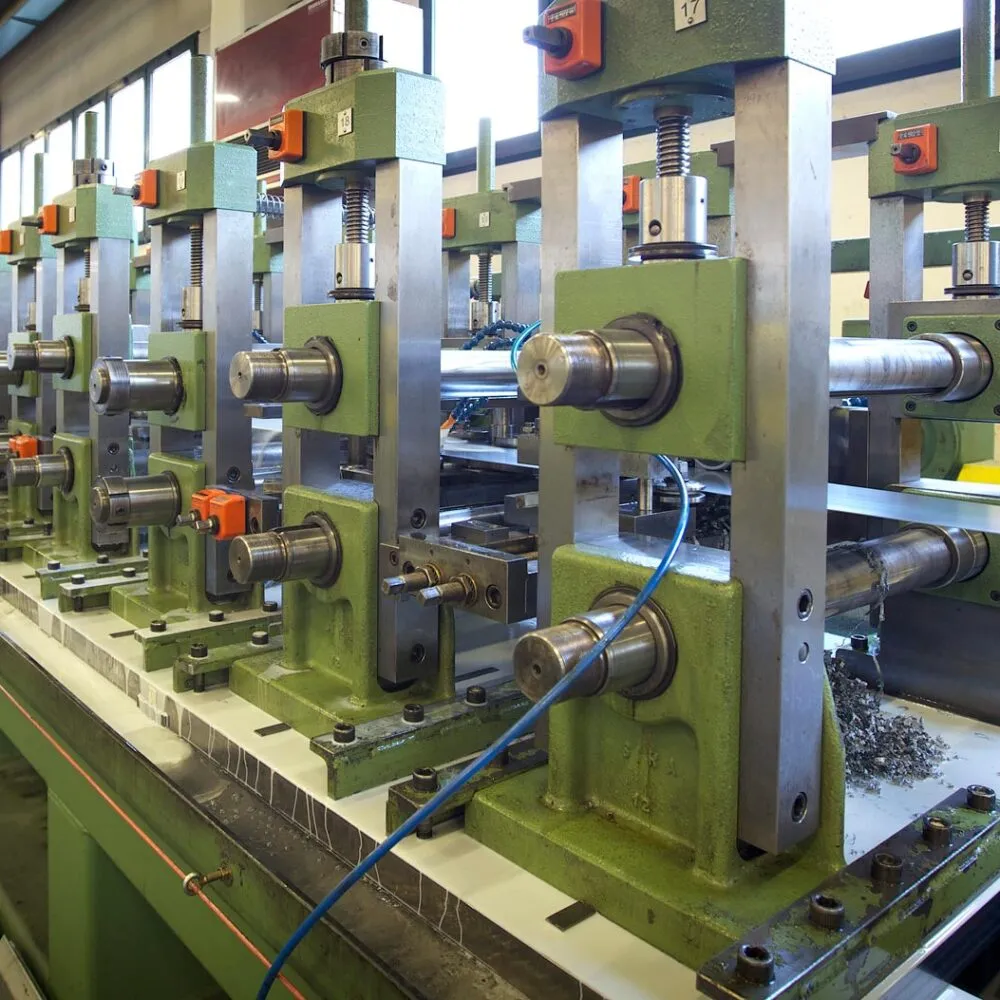

We manufacture custom profiles through specialized metalworking processes, including cold roll forming, cold stamping, bending, calendering, and HF welding.

Tailored processes

Application fields

Our custom special profiles are used across a wide range of industrial sectors: from construction and infrastructure to automotive and furniture, from renewable energy to parking systems, and even in industry and agriculture with vineyard steel posts.

With solid experience, continuous innovation, and proven reliability, Sika is the ideal partner for high-standard custom metal profiles. Our certifications (ISO 9001, ISO 14001, ISO 45001) are a testament to our commitment to excellence.

Materials processed

Discover the materials we cold-form from coils: stainless steel, pickled steel, corten, galvanized steel, aluminum, and copper. We transform metal sheet coils into high-quality custom metal profiles that meet the diverse needs and applications of our clients.

Stay up to date with our industry news, events and updates

Steel vineyard posts

Our corten and galvanized vineyard posts ensure maximum strength and durability. With over 400,000 posts delivered annually, we are the “steel tailors” of vineyard support structures. Download our product catalog or contact us for a free quote.

Custom Cold-Rolled special metal profiles

We manufacture custom cold-rolled steel and aluminum profiles, tailored to specific project requirements. We work with various types of metals, such as stainless steel profiles, galvanized steel profiles, pickled steel, and corten steel, ensuring maximum versatility of use. Thanks to cutting-edge cold roll forming services and metal stamping, we provide reliable solutions for sectors ranging from construction to automotive manufacturing. Technologically advanced processes such as automated punching, steel stamping, profile calendering, and HF welding ensure precision, strength, and flexibility.

Certified quality and custom metal profile design complete our offering, making Sika the ideal partner in industrial fabrication and for custom fabrication projects worldwide.

Read more

Technical processing on metal profiles

The entire metal fabrication process is performed in-house and includes cold stamping, sheet metal punching, metal profile bending, profile calendering, HF welding, precision cutting, and profile assembly. These technologies allow us to produce perforated profiles, formed metal sections, curved profiles, or assembled profiles for integration into modular systems and technical structures.

Materials processed: steels and special alloys

Sika works with a wide range of materials: galvanized steel profiles, stainless steel profiles, corten steel profiles, carbon steel, pickled steel, Magnelis, custom aluminum profiles, and copper profiles. Each material is selected based on mechanical strength, durability, and corrosion resistance.

Application sectors of custom metal profiles

Our custom roll formed steel sections and tailored aluminum profiles are applied in: construction and prefab structures, furniture and kitchens, window and door systems, shower enclosures, architectural lighting, glass railings, ventilated facades, solar mounting structures, industrial automation, forklift components, agriculture, greenhouses, metal fencing, and electrical enclosures. Customization allows us to meet even the most demanding project needs, delivering functionality, durability, and design efficiency.