You might be interested in

News

What are bending profiles and how are they manufactured?

Bending profiles are metal components shaped through controlled deformation processes to achieve precise curves, arches, or complex geometries. These profiles play a critical role in modern architecture, industrial manufacturing, and infrastructure projects where standard straight profiles cannot meet design or functional requirements. Understanding the manufacturing process behind bending profiles helps businesses select the right partner for their custom metal component needs.

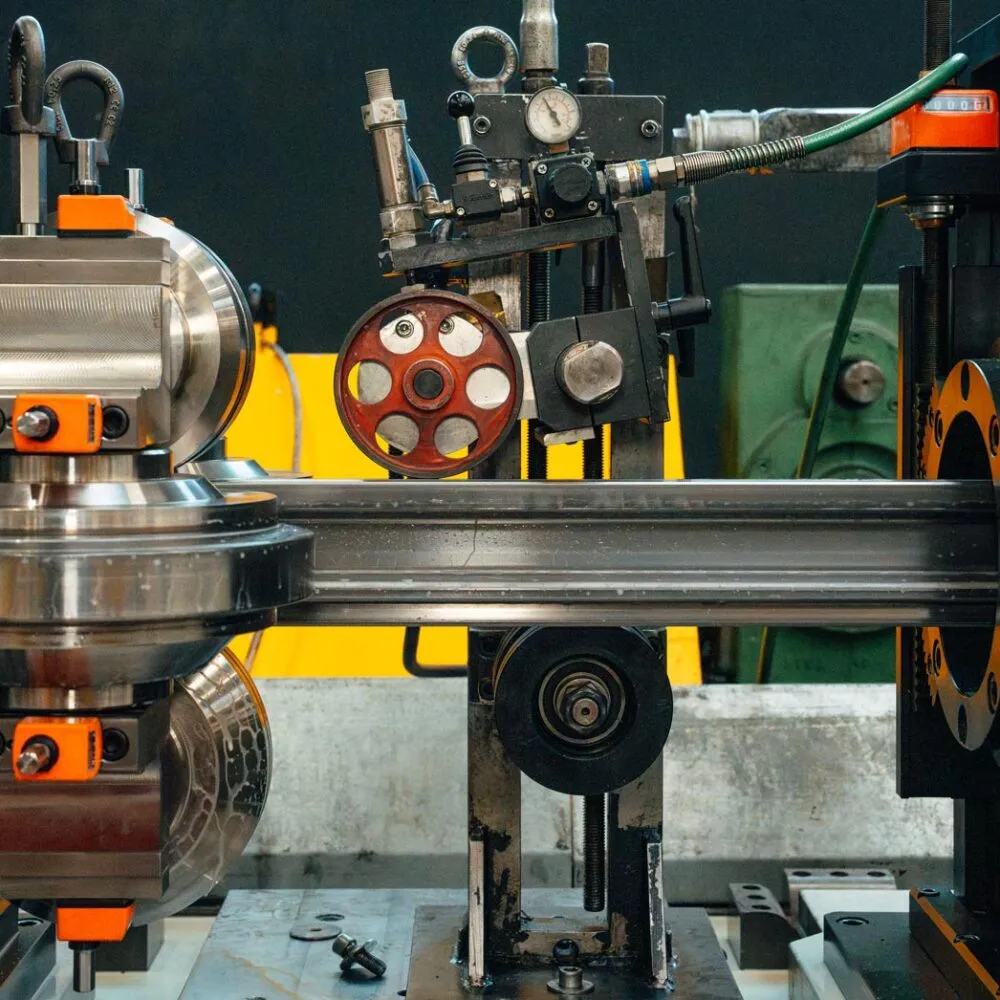

The bending process: technology and precision

The production of bending profiles relies on specialized machinery such as calenders, rollers, and press brakes that apply controlled pressure to metal sheets or strips. This cold-forming technique allows manufacturers to create components with fixed or variable curves while maintaining the material’s mechanical integrity. Unlike hot bending, cold bending preserves the metal’s original strength and ductility, resulting in profiles that perform reliably under demanding structural loads.

Materials used for bending profiles

Bending profiles can be manufactured from a wide range of metals, each offering distinct advantages depending on the intended application. Steel, including stainless, galvanized, and corten variants, provides exceptional strength and durability for structural arches, railings, industrial machinery, and outdoor installations. Aluminum is highly valued for its lightweight properties and corrosion resistance, making it ideal for architectural façades, curtain walls, and urban furnishing elements.

The choice of material directly influences the bending parameters required to achieve precise curvature without compromising surface quality

Key advantages of bending profiles

Cold-formed bending profiles offer significant benefits for industrial and architectural projects:

- Creation of unique sections and tailor-made curves to match specific design requirements

- Reduced need for welds or joints, resulting in cleaner aesthetics and improved structural continuity

- Excellent repeatability and dimensional accuracy across production runs

- Preservation of material strength and ductility through cold-forming techniques

- Flexibility to produce arches, ring profiles, and complex shapes for both functional and decorative purposes

- Compatibility with additional processing such as punching, stamping, and HF welding.

Applications across industries

Bending profiles find extensive use in sectors where curved metal components enhance both functionality and visual appeal. In architecture, they enable the construction of curved façades, roofing systems, and decorative railings.

The automotive and shipbuilding industries rely on bent profiles for structural frames and cabin components. Industrial applications include machinery guards, conveyor systems, and modular shelving structures. Regardless of the sector, the precision of the bending process ensures that each profile integrates seamlessly into the final assembly.

Why choose a specialized manufacturer for bending profiles

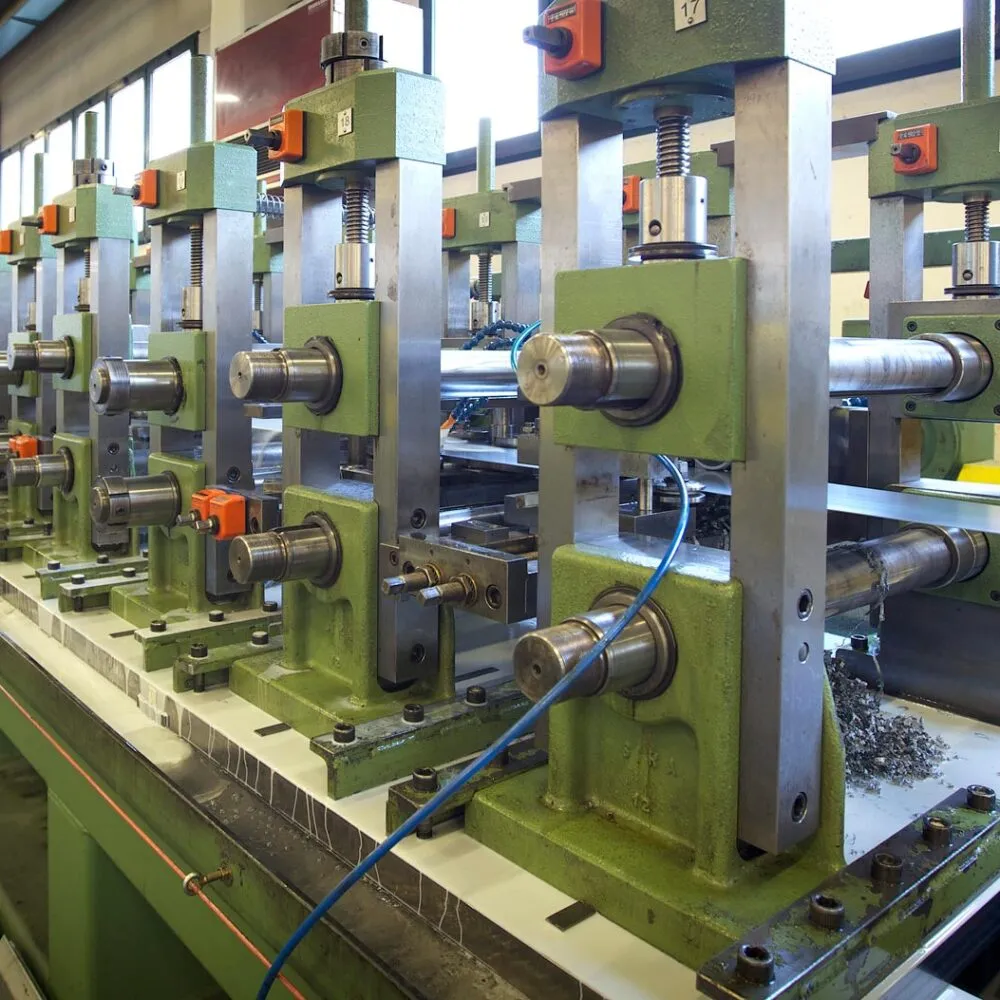

Producing high-quality bending profiles requires advanced equipment, technical expertise, and rigorous quality control at every stage of the manufacturing process.

The complexity of creating precise curves and consistent geometries demands not only state-of-the-art machinery but also experienced engineers and operators who understand the behavior of different metals under controlled deformation.

A specialized manufacturer with in-house capabilities for roll forming, stamping, punching, and bending can deliver components with complex geometries, tight tolerances, and superior surface finishes. Furthermore, certifications such as ISO 9001, ISO 14001, and ISO 45001 demonstrate a commitment to quality management, environmental responsibility, and workplace safety, providing clients with the assurance that their projects are handled according to internationally recognized standards.

Partnering with a certified manufacturer also means benefiting from continuous process improvement, traceability of materials, and consistent documentation, all of which are essential for demanding industrial and architectural applications.

Sika: your partner for custom bending profiles

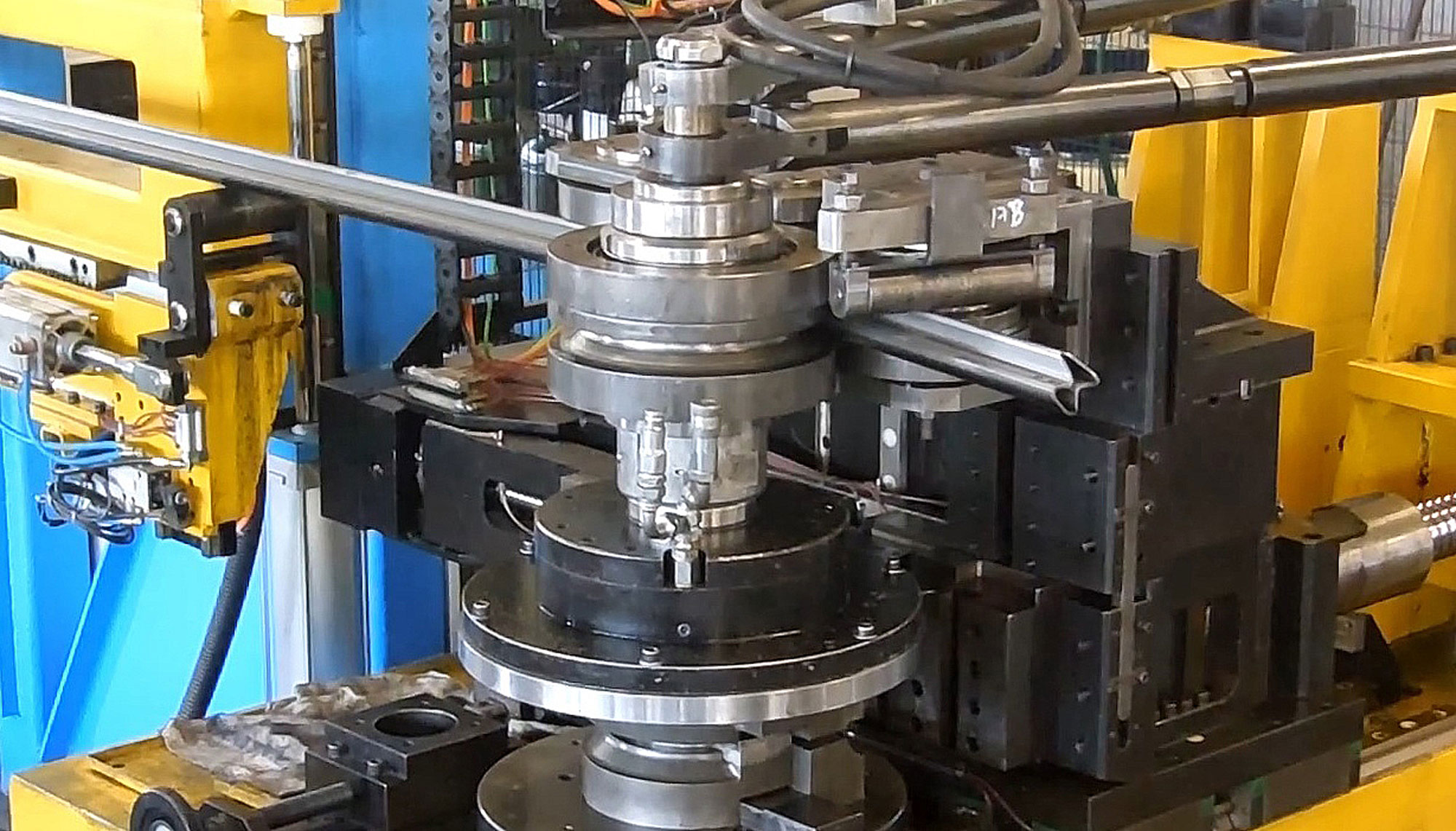

Sika is a leading manufacturer of custom cold-formed metal profiles, with decades of experience in delivering precision-engineered solutions for clients worldwide. The company specializes in bending profiles for aluminum and steel, offering tailor-made curved components for construction, design, automotive, and industrial applications.

With advanced in-house capabilities including roll forming, cold stamping, calendering, punching, and HF welding, Sika transforms metal coils into high-performance profiles with complex geometries and strict dimensional tolerances. The company works with a comprehensive range of materials, from stainless and galvanized steel to corten, aluminum, and copper, ensuring maximum versatility for every project requirement.

Certified to ISO 9001, ISO 14001, and ISO 45001 standards, Sika Profili combines technical expertise, continuous innovation, and a customer-centered approach to deliver reliable solutions that meet the most demanding specifications.