Know how

technologies and cold roll forming processes

Sika’s technology in custom roll forming of profiles and tubes

At Sika, excellence in producing special profiles stems from the integration of cutting-edge technologies and deep technical expertise. Our continuous innovation allows us to deliver custom roll formed profiles that meet even the most complex client requirements. With advanced processes such as cold roll forming, profile calendering, metal bending, HF welding, and laser welding, we transform high-quality materials into high-performance, custom-engineered solutions.

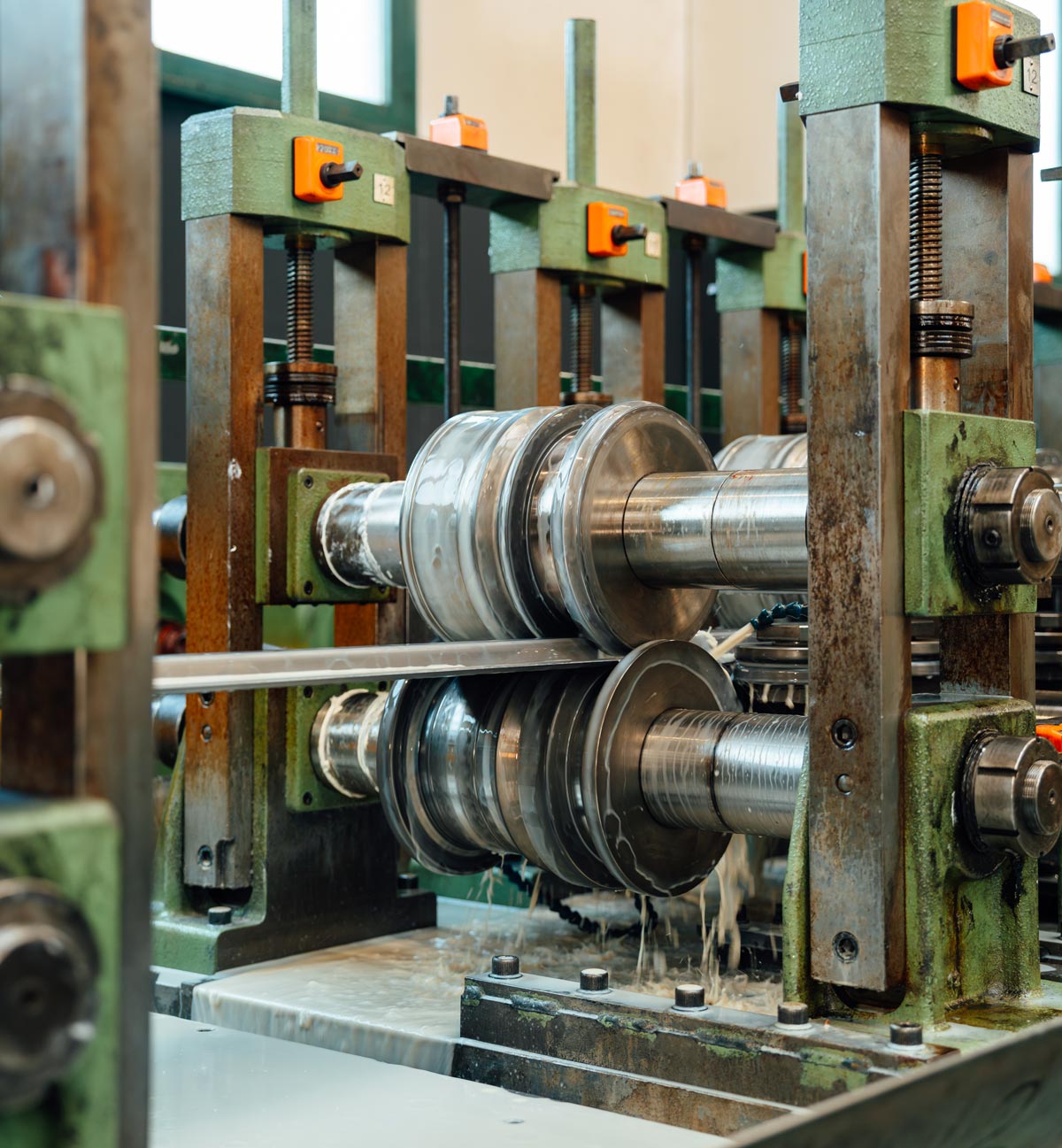

Cold roll forming

Cold roll forming is one of our core competencies, allowing us to shape metal sheets without altering their mechanical properties. Using a continuous roll forming process, we produce consistent and precise cross-sections along the entire profile length. This method is ideal for manufacturing cold-formed profiles from large-scale metal coils in high volumes, ensuring efficiency and cost-effective production.

Cold metal stamping

Our cold stamping process is essential for creating metal components and accessories with extremely high precision. Including cold stamping of steel, this technique enables the production of parts with tight tolerances and excellent repeatability, minimizing waste while offering an outstanding balance of quality, reliability, and cost competitiveness.

Additional processing

In addition to cold roll forming and roller shaping, Sika offers a wide range of metalworking processes to meet various production needs.

Bending and forming

These processes allow the creation of structures with exact angles—essential in industries such as furniture manufacturing and plant engineering.

CNC metal punching

These processes allow the creation of structures with exact angles—essential in industries such as furniture manufacturing and plant engineering.

HF Welding

Perfect for producing tubular profiles, this welding method guarantees strong, sealed joints and high mechanical performance.

Laser welding technology

This advanced welding process allows for complex and highly accurate welds, making it ideal for custom profiles required in sectors like aerospace and medical, where precision and performance are critical.

Press brake bending

This process allows the creation of accurate angles and forms, commonly used in furniture systems and technical installations.

Profile calendering and curving

Used to create cylindrical or conical shapes, this method is especially suited for architectural and industrial applications requiring complex geometries.

Certifications

Every profile undergoes strict quality control procedures, ensuring that each custom profile meets technical specifications and customer expectations. We collaborate closely with our clients to optimize production results, delivering highly customized and competitive solutions.

Our custom special profiles are used across a wide range of industrial sectors: from construction to infrastructure, from automotive to furniture, from renewable energy to parking systems, and in heavy industry and agriculture including steel vineyard posts.