Custom metal profiles for industry

Versatile and reliable solutions for industrial applications

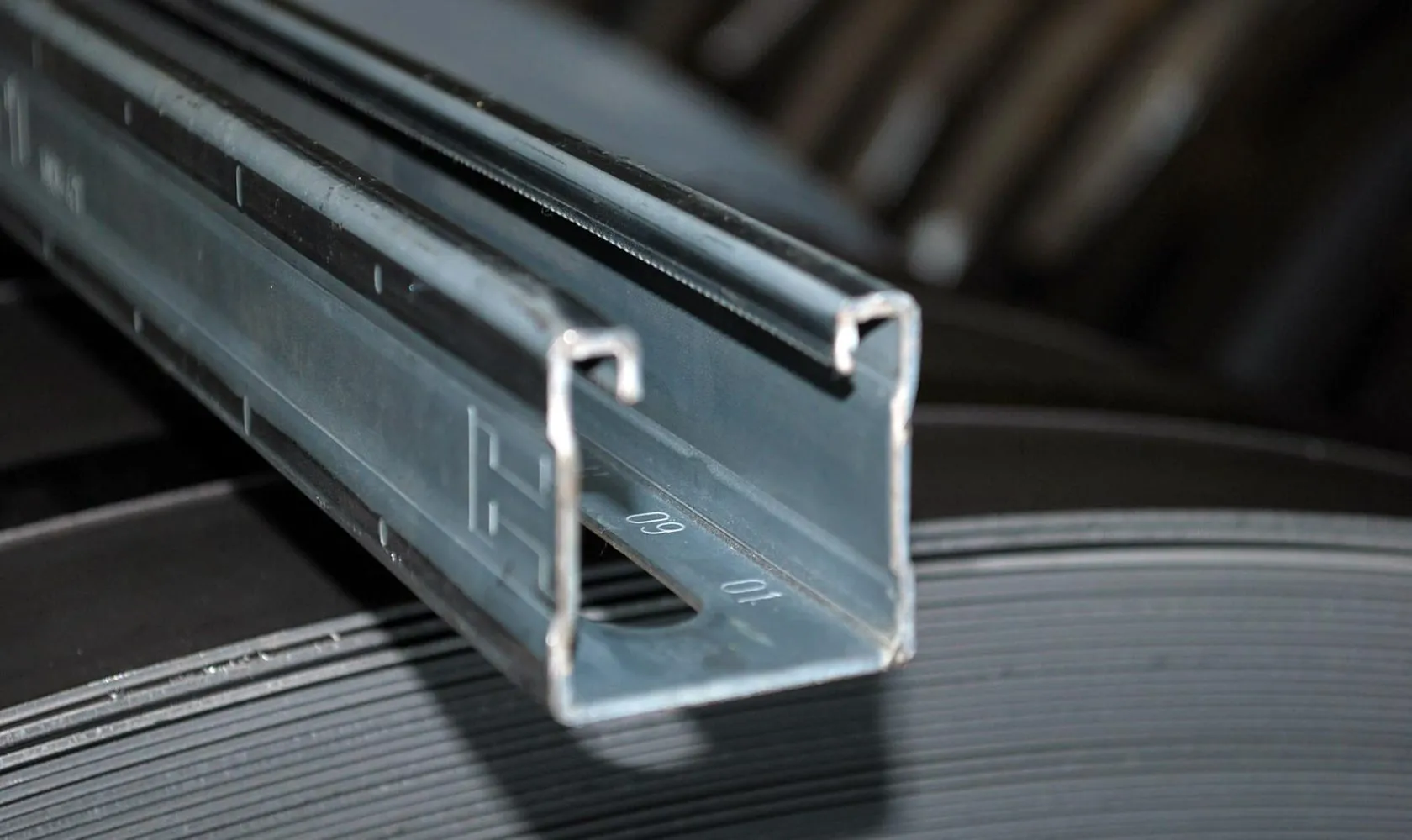

In the industrial sector, the quality and precision of structural components directly affect the efficiency, safety, and lifespan of equipment and systems. Sika manufactures custom metal profiles for industry, engineered to meet a wide variety of application needs. Our profiles made from galvanized steel, stainless steel, and aluminum are processed through cold roll forming, punching, HF welding, calendering, and 3D laser cutting to deliver advanced, highly customizable technical solutions.

Advanced technologies for custom profiles

Thanks to cold roll forming, we are able to produce custom structural metal profiles with complex and highly tailored geometries. This process ensures that both aluminum and steel retain their original mechanical properties, providing components with excellent strength and long-term stability.

The quality of the finished product results from strict quality control throughout the entire production chain. From raw material selection to surface finishing, every phase is tracked and verified to ensure mechanical resistance, durability, and full compliance with modern industry standards.

Custom metal profiles for a wide range of industrial applications

Sika offers a comprehensive range of metal profiles for industry. Our solutions are designed to adapt to various industrial sectors and are developed to spec in close collaboration with the client.

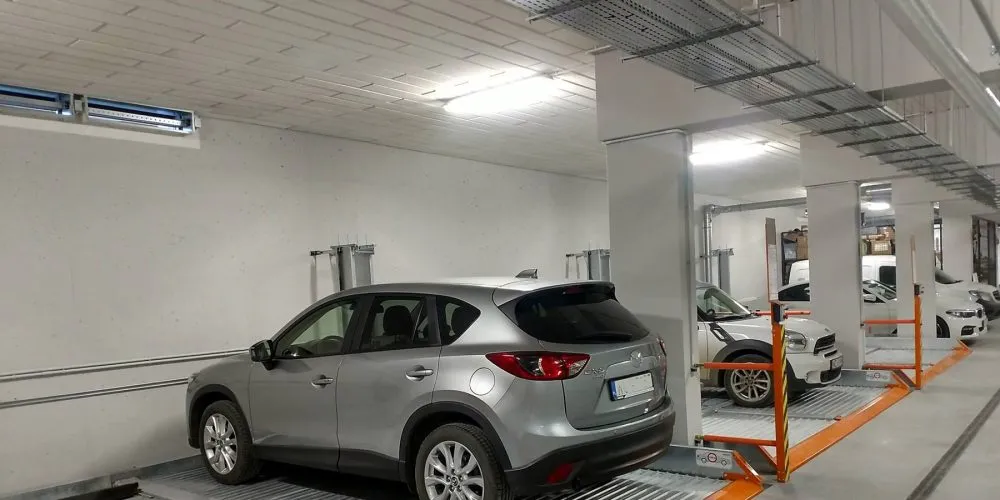

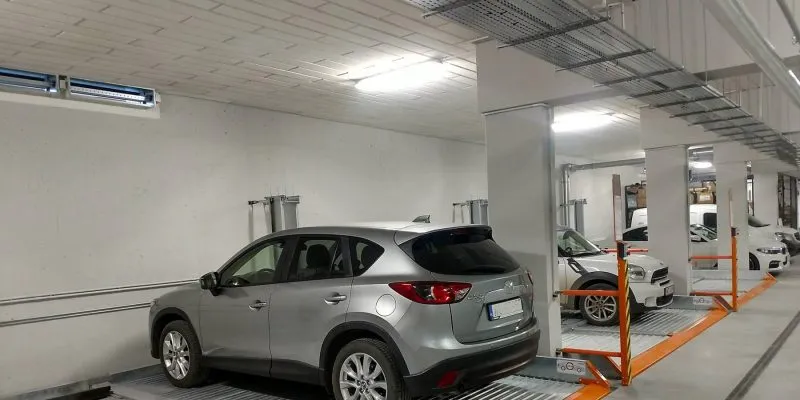

Applications of custom profiles and cold-stamped accessories

Custom metal profiles for industrial use are employed in load-bearing structures, frames, coverings, and handling systems. Some of the most common applications include: electrical enclosures, automated parking systems, industrial shelving, technical furniture, and components for conveyor systems. Cold-stamped accessories complement the profiles, ensuring precise, solid, and functional assembly. Cold-forming processes allow for complex geometries and tight tolerances while maintaining the mechanical properties of the materials.

Advantages of cold roll forming

Excellent surface finishes and absolute precision

Thanks to cold roll forming technologies and tight-tolerance processes, metal profiles for industry can be further customized with chrome plating, protective films, or dedicated coatings. The goal is to ensure a superior surface finish essential in applications where every detail makes a difference.

Support from design to production

Sika supports professionals from the earliest design stages, offering expertise and guidance on material selection, required processes (such as punching or bending), and the most suitable surface finishes. The result is metal profiles for industry that are not only durable and functional but also aesthetically refined.

The right profile for every idea

Whether it’s high-end residential environments or modular systems for contract applications, Sika’s versatile solutions make it possible to produce components with complex geometries, integrating perforations and custom features. This high level of customization translates into a competitive advantage, allowing customers to express their vision and develop unique products that meet the highest standards.

Why choose Sika for profile manufacturing

Quality is not just a goal but a continuous journey of daily improvement.

Choosing Sika means partnering with an experienced, flexible, and quality-driven manufacturer. Our strength lies in our ability to transform your ideas into fully customized profiles ready for industrial application. We provide technical support throughout every stage of the process from prototyping to full-scale production. Our manufacturing ensures dimensional accuracy, mechanical strength, and full compatibility with automated systems.

Custom processing and certified quality

Every profile manufactured by Sika is the result of a controlled and traceable production process, compliant with international quality standards. Our custom metal profile processing includes bending, punching, drilling, and complex cutting, all performed with state-of-the-art machinery. Thanks to our production flexibility and decades of experience, we deliver reliable, durable, and fully customized components for any industrial sector. Moreover, the use of materials such as aluminum, stainless steel and carbon steel ensures a wide range of options in terms of weight, finish, and long-term durability.

Application sectors

The applications of our custom metal profiles for industrial use span multiple sectors, including construction and architecture, mechanical engineering, furniture manufacturing, automotive, photovoltaic systems, and agriculture. Thanks to the combination of advanced technologies and high-quality materials, Sika delivers solutions that integrate seamlessly into complex and innovative projects. Our components not only meet the highest performance standards but also ensure refined, functional design. Each tailor-made solution is engineered to meet specific requirements, supporting the development of durable, high-precision products tailored to industrial needs.

Contact us to discover how Sika can support your project with high-quality custom metal profiles and tailor-made industrial solutions.

Our proven experience, continuous innovation, and strong industry presence make us the ideal partner for companies seeking high-end solutions. Choosing Sika for the production of custom metal profiles means relying on a company with the highest quality standards. Discover the certifications that confirm our commitment to excellence.