Punching and drilling

for custom profiles and accessories

Sheet metal drilling: tailor made solutions for every design need

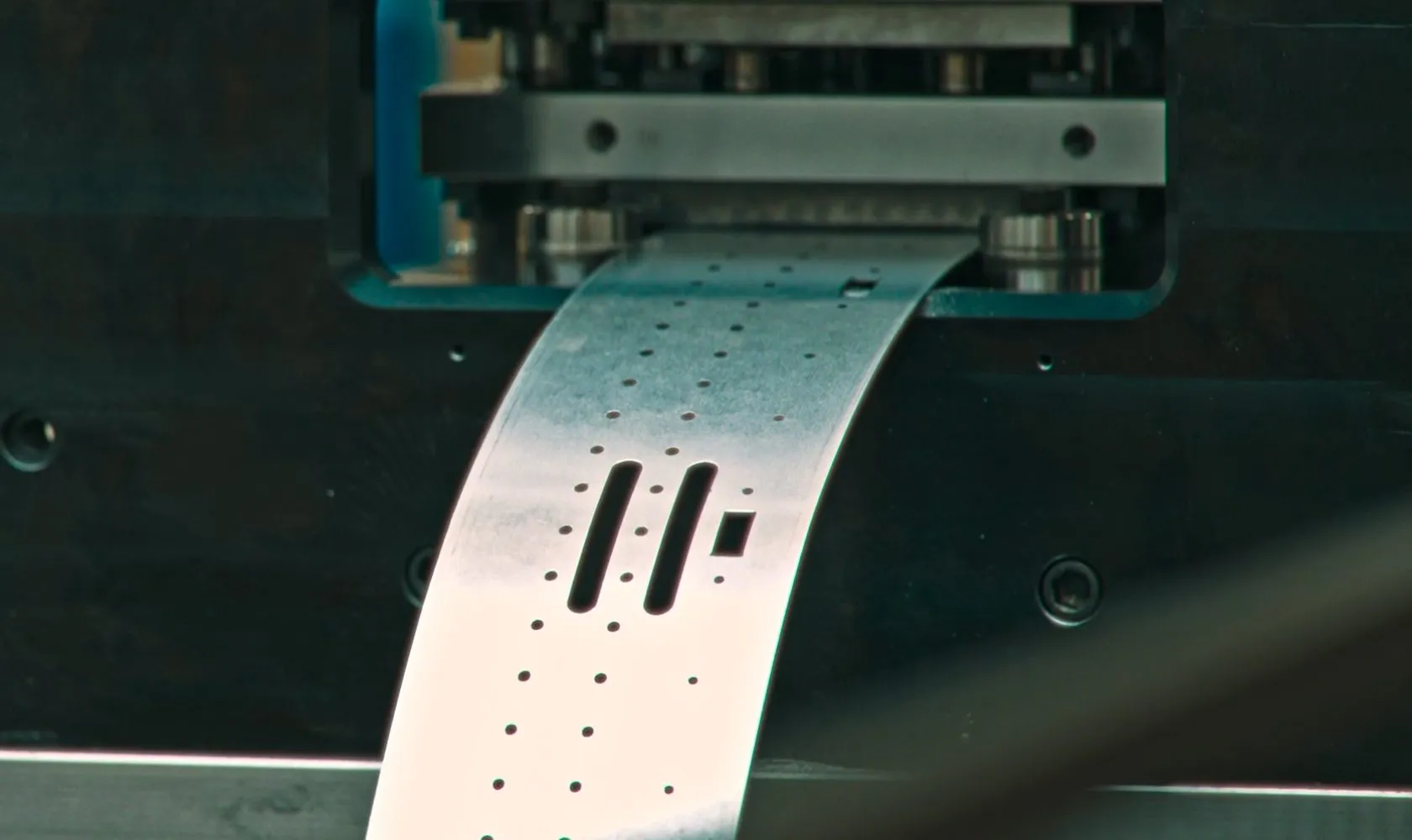

Sheet metal punching and drilling is a process that involves creating holes, slots, or other openings on the metal surface, often performed directly on the coil strip. This technique, known as coil pre punching, makes it possible to obtain parts already prepared for the next processing steps, avoiding manual intervention or later reworking.

Read more

With coil punching, sheet metal can be processed inline, without interrupting the production cycle. This enables continuous operation and significantly reduces overall processing time. Another key advantage is the ability to create holes and cut outs based on custom technical drawings, offering excellent design flexibility for shelving, electrical enclosures, displays, and fencing. In addition, the use of photocell-based systems and CNC machinery ensures decimal level tolerances, guaranteeing extremely precise distances between the head and tail of the strip.

Applications and sectors of use

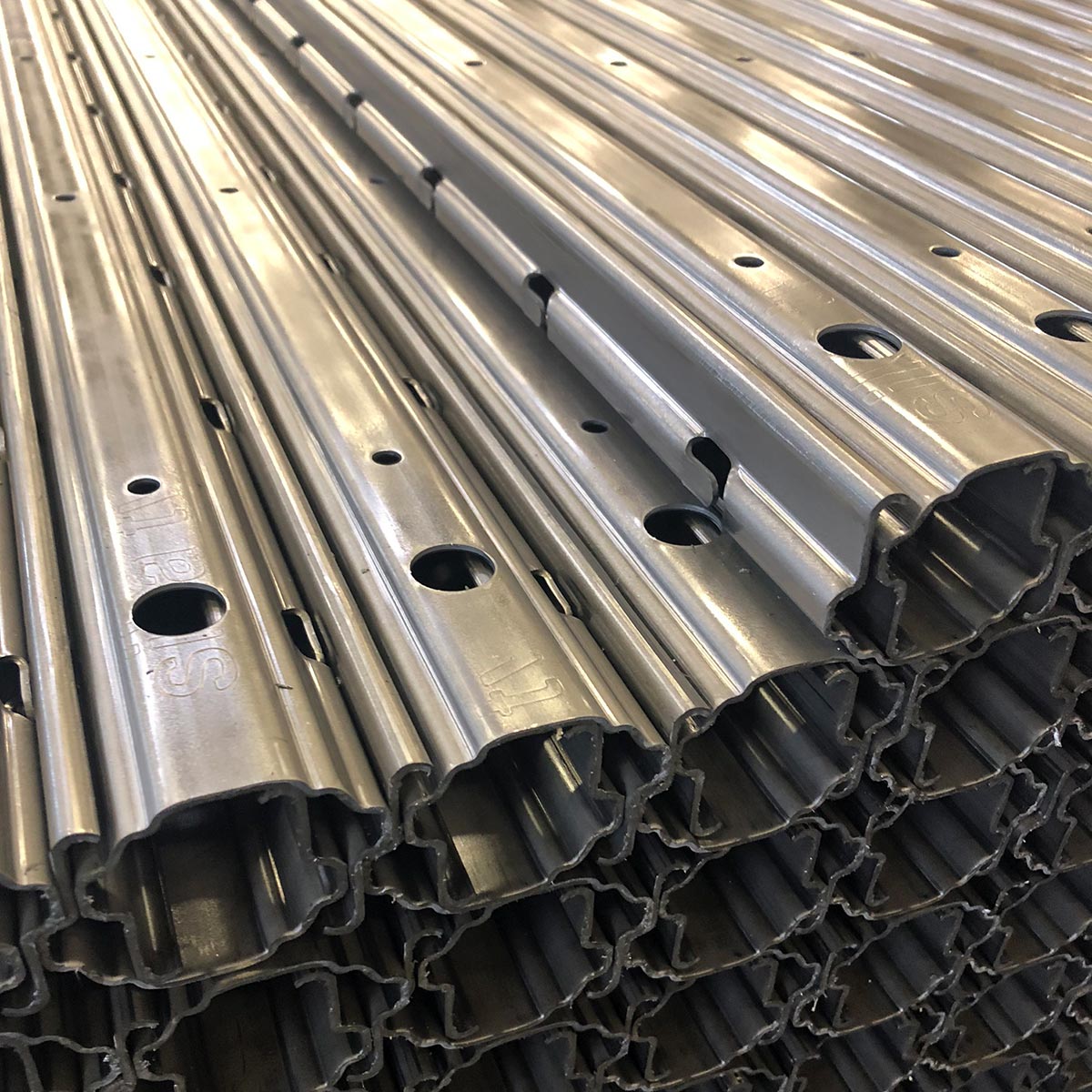

Sheet metal punching and drilling solutions are widely valued in many industrial sectors. In the production of shelving uprights, production efficiency and design flexibility are essential to meet load bearing, stability, and customization needs. In the field of electrical enclosures, coil pre punching makes it easy to integrate cable passages and fastening systems. Fencing, vineyard posts, movable and equipped walls, commercial displays, and photovoltaic systems also benefit from integrated coil drilling and sheet metal punching processes, enabling the creation of robust and functional structures.

Key advantages

Sheet metal punching completes the range of secondary processes, allowing the creation of more complex shapes and geometries such as dimples, stampings, slots, and embossing. Often integrated into the inline roll forming process, coil punching offers additional benefits in terms of efficiency and production flexibility.

Thanks to automation, production speed increases, reducing overall processing time.

Openings can be custom-made according to technical drawings and client specifications.

Cold working preserves the metal’s mechanical properties, ensuring strong and long-lasting components.

Forming parts with integrated curves often eliminates the need for welding and joints, improving strength and aesthetics.

With SIKA, cold roll forming becomes synonymous with innovation and reliability offering solutions that transform simple metal coils into high-performance components, ready to meet the challenges of even the most demanding projects.

Other processes

Through careful management control and continuous improvement of our production processes, we aim to satisfy all stakeholders: clients, suppliers, and collaborators. Our commitment also extends to compliance with safety regulations, reduction of complaints, and on time delivery always fostering a team oriented approach. With this philosophy, cold roll forming becomes not just a technical process, but a symbol of our dedication to delivering high standards, ensuring production flexibility, and steadily expanding our presence in international markets.