Joining of closed profiles

profile joining and welding techniques

Custom profile joining: welding and assembly techniques for durable solutions

Closed profile joining plays a key role in the production of high-quality metal components and structures. From in-line to off-line processes, several techniques allow for stable and reliable joining of profile edges while maintaining the material’s properties and the final product’s aesthetics. Depending on the type of metal such as steel, stainless steel, or non ferrous alloys and the desired outcome, specific profile joining or welding methods can be selected.

Joining technologies

High-frequency induction welding

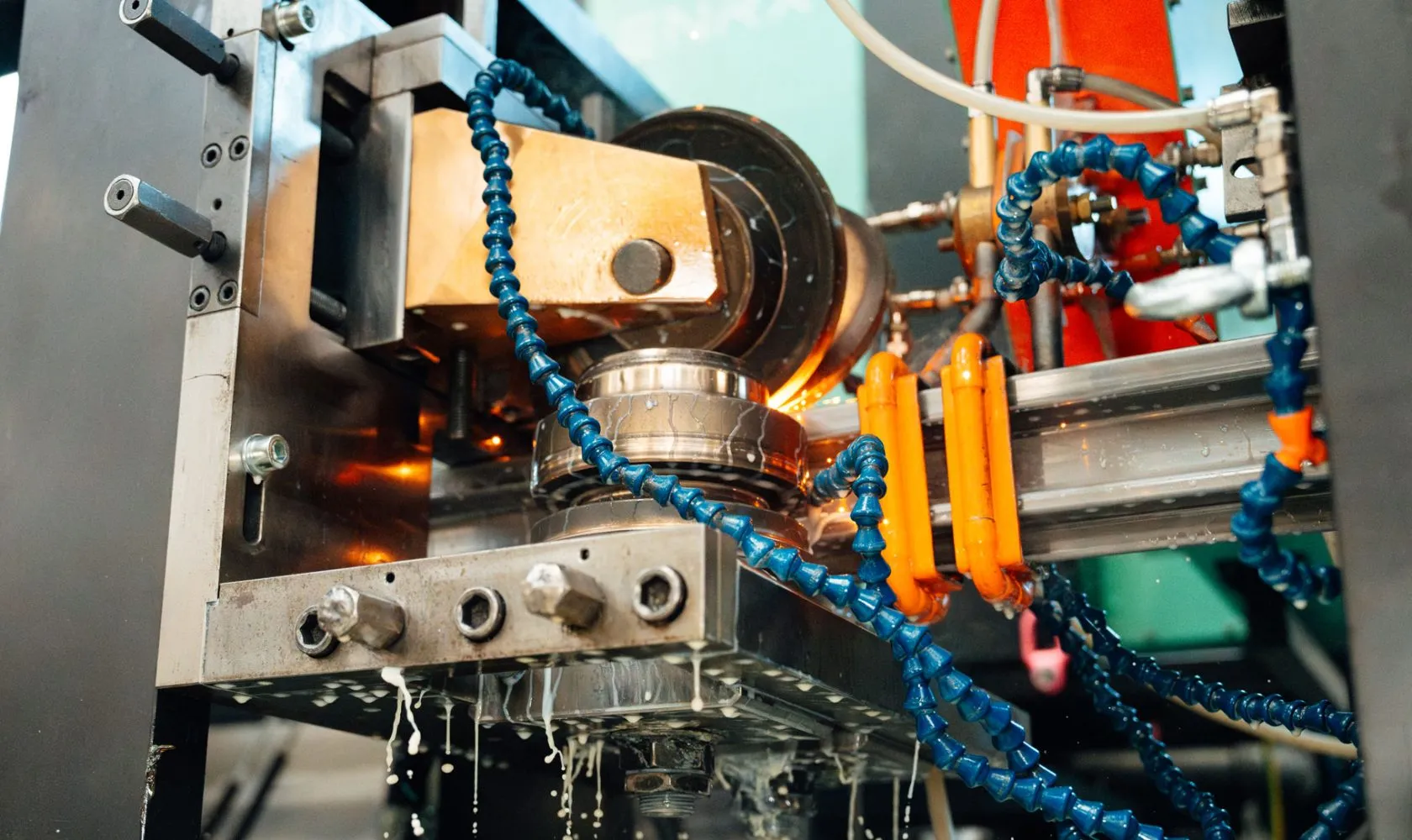

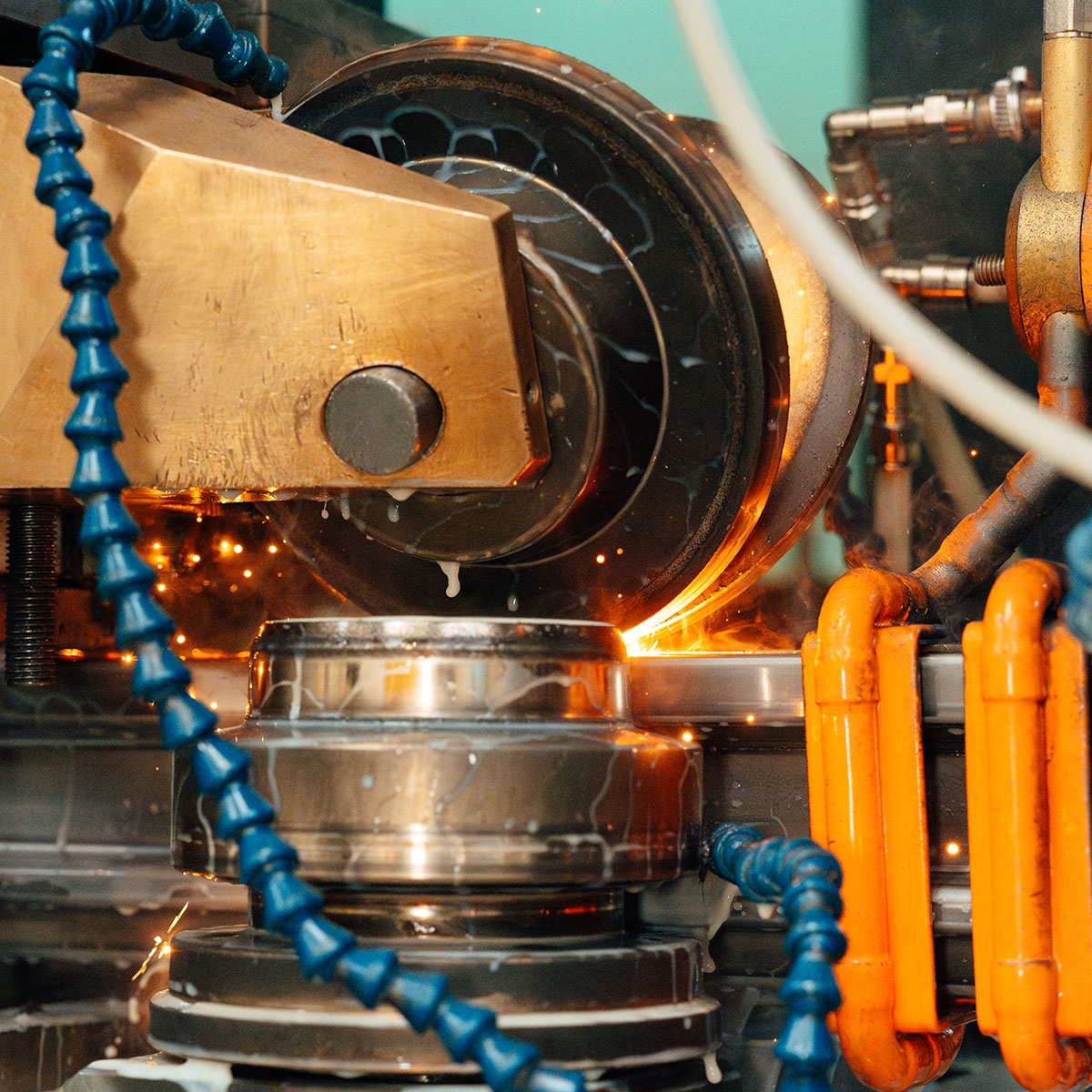

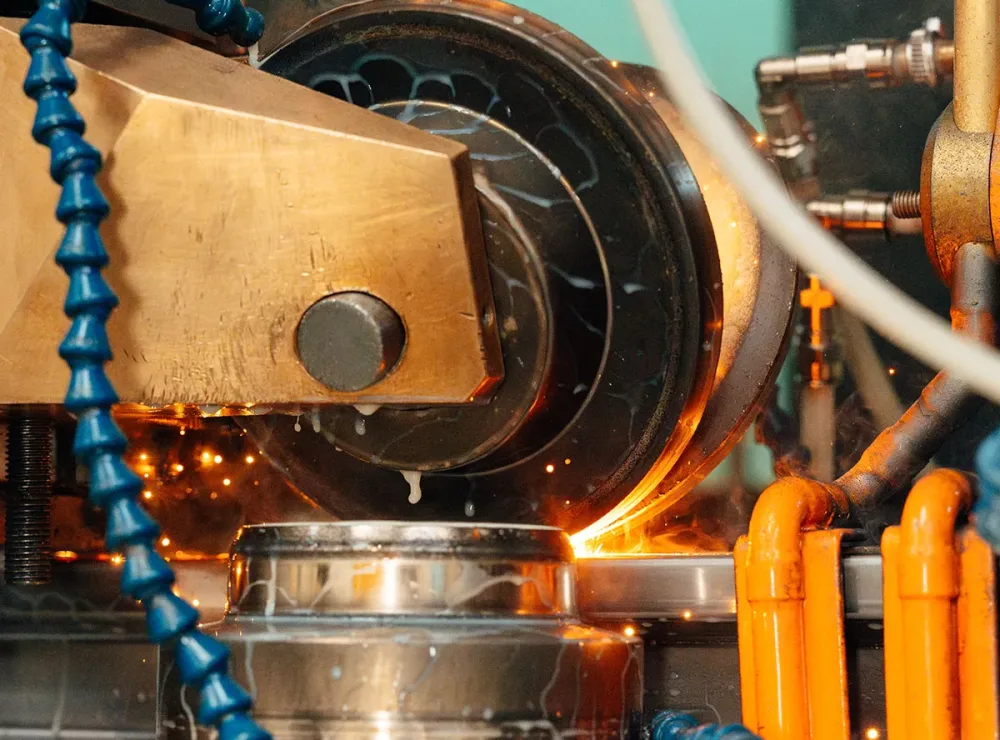

Among the most common solutions for closed metal profiles, high-frequency (HF) induction welding is performed directly in-line during the cold roll forming process.

Lock seaming

In lock seaming, two metal edges are folded and pressed together, ensuring a strong and waterproof joint. This technique is often used in sectors requiring protection of the surface coating.

Clinching

Clinching uses controlled pressure to interlock two sheet metal layers without the need for filler material. This method provides reliable joints with minimal bulk and a clean finish.

In-line HF induction welding

High-frequency (HF) induction welding is performed during the cold roll forming phase. This non contact process between the heating element and the metal ensures a continuous and uniform weld seam, eliminating impurities and localized deformations. When required, subsequent external or internal scarfing allows for a high-quality aesthetic and functional result without compromising the mechanical strength of the profile.

Benefits of profile welding and joining

Profile joining techniques, from high-frequency induction welding to lock seaming, clinching, and spot welding, meet a wide range of needs in terms of strength, sealing, and aesthetic finish. This flexibility allows for optimized production times, streamlined post-processing, and the creation of components for sectors such as construction, urban furnishing, automotive, and industrial machinery. The ability to tailor the joining process to technical drawings and project specifications makes each profile unique.

Each joining method (welding, lock seaming, clinching) ensures a solid bond designed to withstand mechanical stress and environmental exposure without compromising overall stability.

The ability to select the most suitable joining technique based on material and geometry makes it possible to meet diverse design needs and create custom profiles.

Integrating joining methods into the production cycle saves time and simplifies workflows by eliminating the need for external operations or extra steps.

Cold joining methods such as lock seaming or clinching preserve the surface finishes of profiles, protecting them from damage or aesthetic alterations during the joining process.

With SIKA, cold roll forming becomes a symbol of innovation and reliability, offering solutions that transform simple metal coils into high-performance components ready to meet the challenges of the most ambitious projects.

Other processing

Through rigorous management control and the continuous improvement of our production processes, we strive to satisfy all stakeholders: customers, suppliers, and collaborators. Our commitment includes compliance with safety regulations, reducing complaints, and ensuring on-time deliveries always with a team driven approach. With this philosophy, cold roll forming becomes more than just a technical operation: it represents our dedication to delivering high standards, ensuring production flexibility, and constantly expanding our presence in international markets.