Metal profile bending

for precise curves and complex shapes

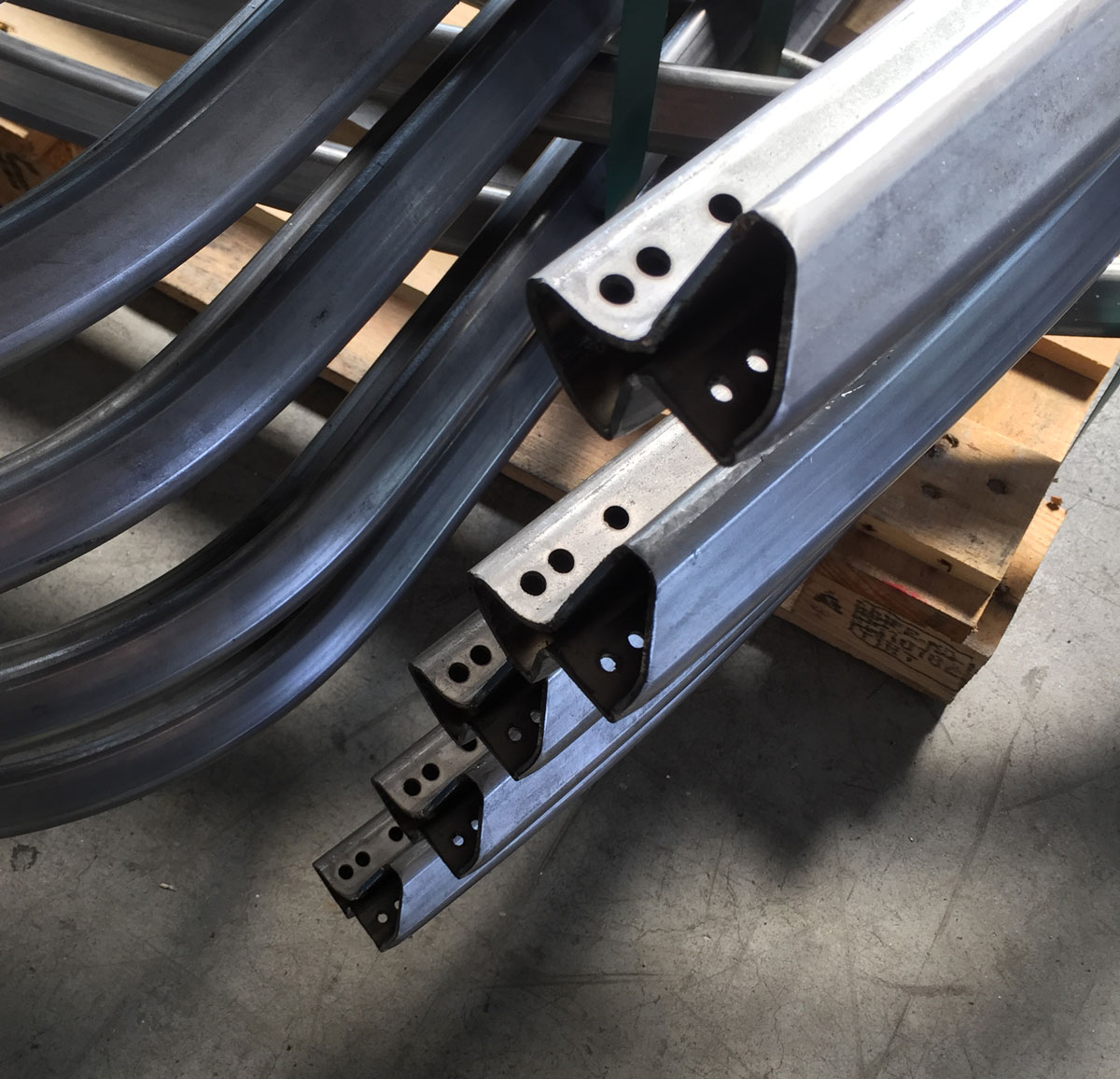

Bending aluminum and steel profiles

Metal profile bending is a process that deforms elements such as beams, tubes, or shaped sheets, giving them curved geometries of various radii and complexity. Using dedicated machinery, the metal is gradually bent until it reaches the desired radius, maintaining high standards of precision and consistency. This process, typically carried out cold, preserves the mechanical properties of the material and is ideal for applications in construction, architecture, mechanical industry, and design.

How bending works

The metal profile bending process is carried out using calenders or cold bending presses. With the help of rollers, the metal is gradually deformed into the desired curve without compromising the material’s strength. Accurate control of parameters such as bending radius, pressure, and feed rate ensures consistent and repeatable results, whether for single components or large production runs.

Applications and advantages

Metal profile bending, including aluminum and steel profile bending, finds wide application in sectors such as furniture, architecture, the automotive industry, shipbuilding, and industrial construction. Key benefits include:

Possibility to create unique sections and tailor-made bends.

Cold forming reduces the need for welds or joints.

Arches, ring profiles, and complex shapes enhance both functionality and aesthetics.

Cold bending maintains the metal’s strength and ductility.

Aluminum and steel profile bending

Aluminum profile bending

Aluminum is highly valued for its lightness and corrosion resistance. Cold bending of aluminum profiles requires precise pressure control, enabling perfect curves suited for curtain walls, roofing systems, and urban furnishing elements.

Steel profile bending

Steel’s strength and ductility make it ideal for both structural and decorative applications. Controlled bending of steel profiles maintains mechanical integrity, ensuring reliability in structural arches, railings, carpentry, and industrial machinery components.

With SIKA, metal profile bending becomes a hallmark of innovation and reliability delivering solutions that turn simple metal coils into high-performance components, ready to meet the most demanding project challenges.

Other processing

Through careful management control and continuous improvement of production processes, we aim to satisfy all stakeholders: clients, suppliers, and collaborators. Our commitment extends to safety compliance, reduction of complaints, and timely deliveries always prioritizing teamwork. With this philosophy, cold profiling becomes not only a technical operation but also a symbol of our commitment to high standards, production flexibility, and ongoing expansion into international markets.