Cold roll forming

the roll forming process for producing custom metal profiles

Cold metal profiling: innovation and technology for custom profile production

Explore the world of cold roll forming with SIKA, a leader in the production of custom metal profiles. Thanks to advanced technology and fully automated processes, we manufacture cold-formed profiles and tailor-made solutions that meet even the most complex requirements. Our integrated roll forming system transforms metal coils into high-quality products, ensuring precision, efficiency, and controlled costs.

Our capabilities

Strip thickness:

From 0.4 mm to 4 mm

Strip width:

Up to 550 mm

Profile length:

From 200 mm to 1300 mm

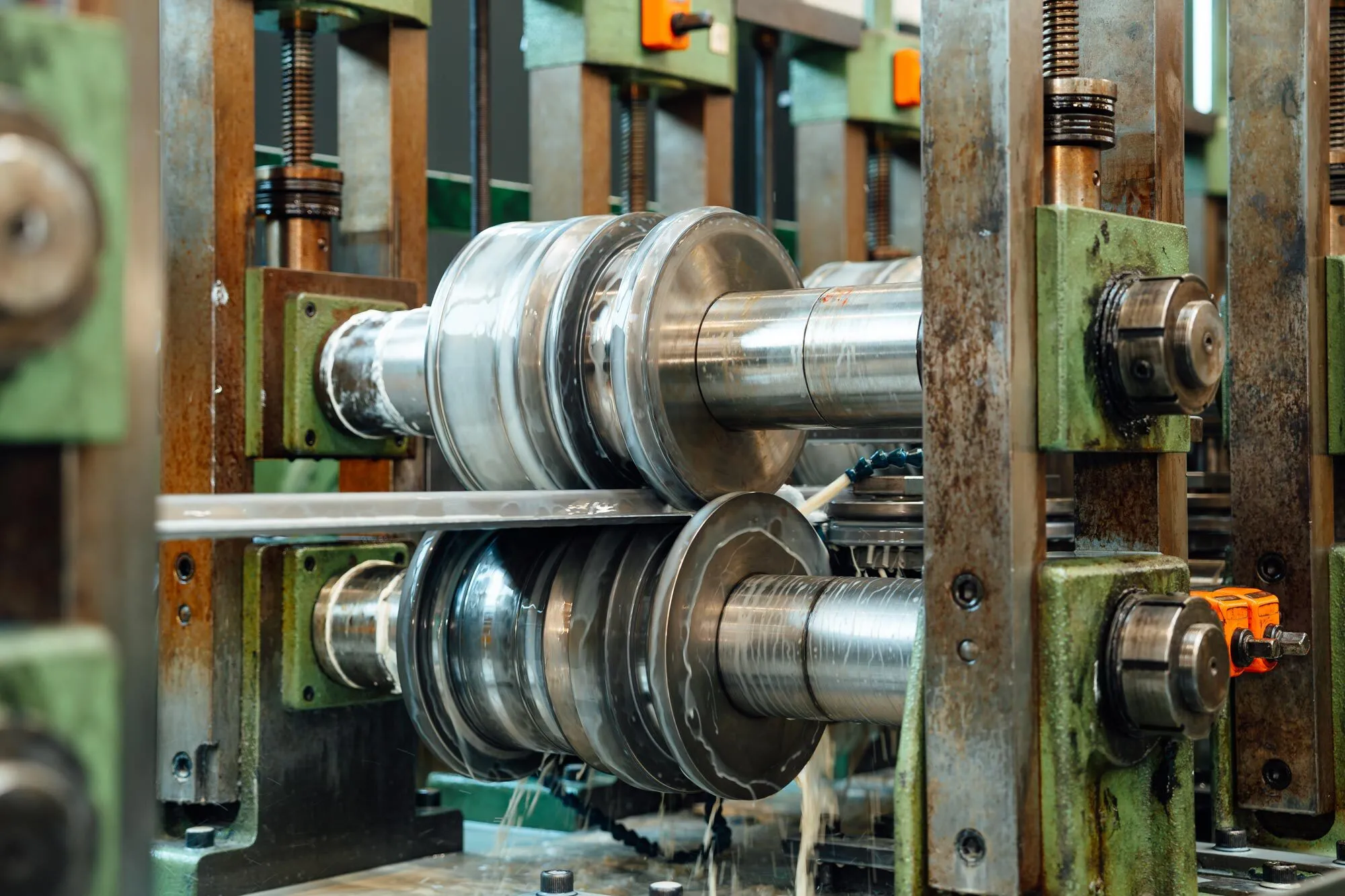

The cold roll forming process

What is cold roll forming?

Cold roll forming is a sheet metal processing method performed at room temperature, without the use of heat sources. During this process, metal is gradually shaped through a series of rollers until the desired section is achieved. Also known as roll profiling, this method enables the continuous production of cold-formed profiles with low costs and short lead times ideal for custom components in industrial and construction applications.

The advantages of cold roll forming

The cold roll forming technique is the ideal solution for those seeking long-lasting products, high-volume output, and consistent profile geometry. These profiles are used in a wide range of sectors: from construction to automotive, including shipbuilding and electronics. Just as importantly, the precision ensured by roll forming is also essential in fields such as jewelry making and watchmaking.

Our numerically controlled processes ensure extremely tight tolerances and consistent uniformity across profiles.

The continuous system allows for high volume output in short timeframes, reducing production costs.

Inline integration of additional processes enables completely tailored solutions adaptable to any project.

Cold working preserves or even enhances the metal’s intrinsic properties, ensuring high-quality and durable products.

With SIKA, cold roll forming becomes synonymous with innovation and reliability, delivering solutions that transform simple metal coils into high-performance components ready to meet the most ambitious project challenges.

Explore other processes

Through careful production management and continuous process improvement, we aim to satisfy all stakeholders: clients, suppliers, and team members. Our commitment extends to safety compliance, reduction of complaints, and on-time delivery, always favoring a team-oriented approach. With this philosophy, cold roll forming becomes not just a technical process, but a symbol of our commitment to high standards, production flexibility, and constant growth in international markets.