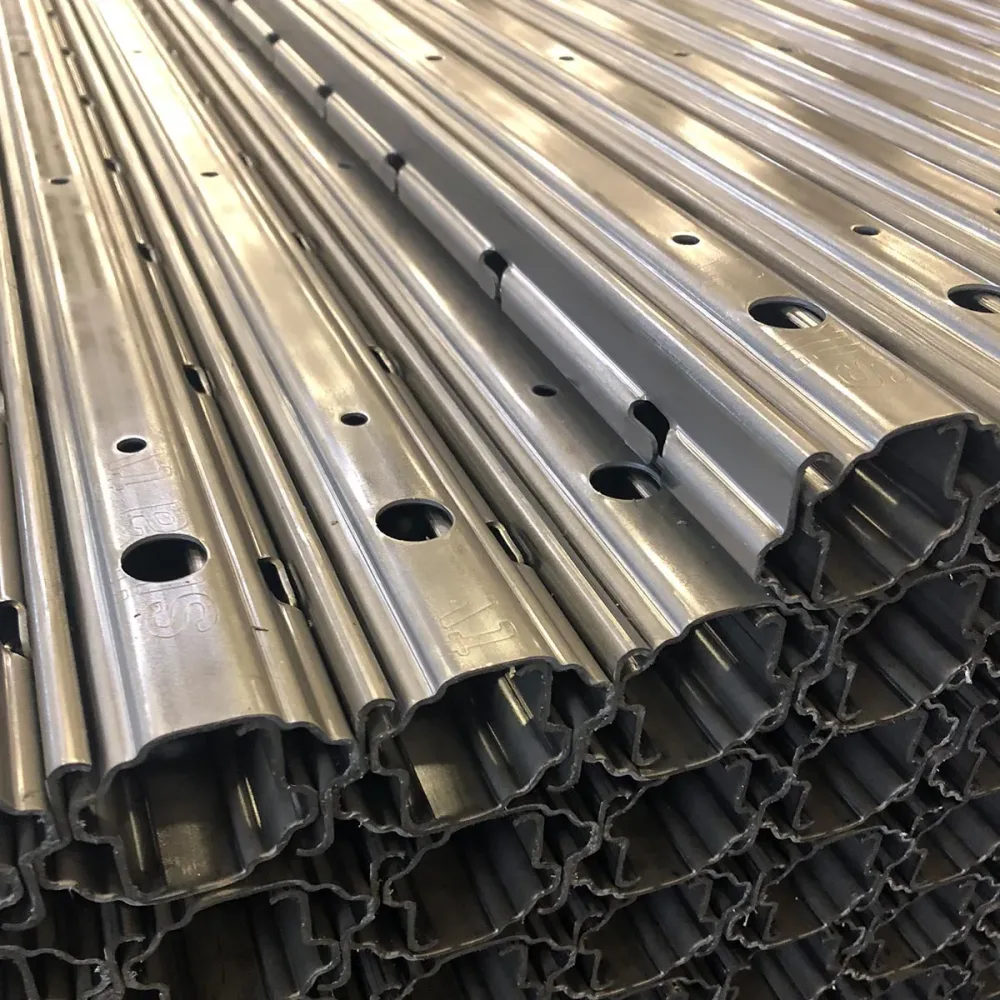

Galvanized steel profiles

Galvanized steel profiles: corrosion protection and versatility for long-lasting projects

Galvanized steel profiles are an excellent solution for creating structures that require high resistance to weathering, a good balance between strength and weight, and low production costs.

The steel undergoes a galvanizing process generally hot-dip or electroplating that deposits a layer of zinc on the surface, creating a protective barrier against corrosion. The result is a material suitable for a wide range of applications, from the construction and industrial sectors to urban furniture and metal carpentry.

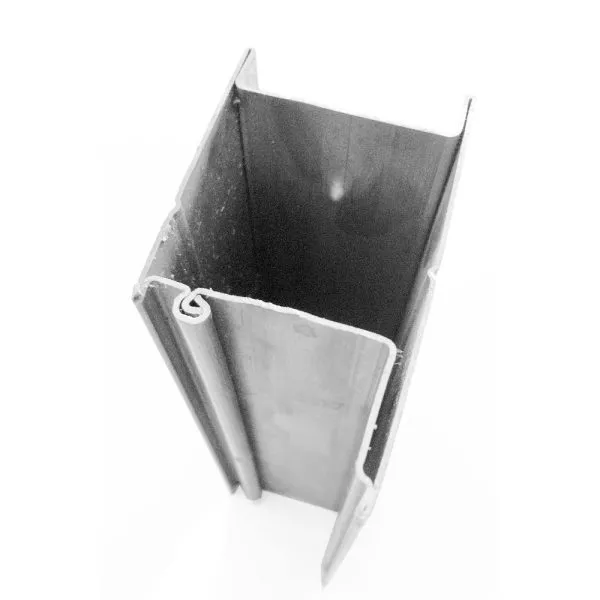

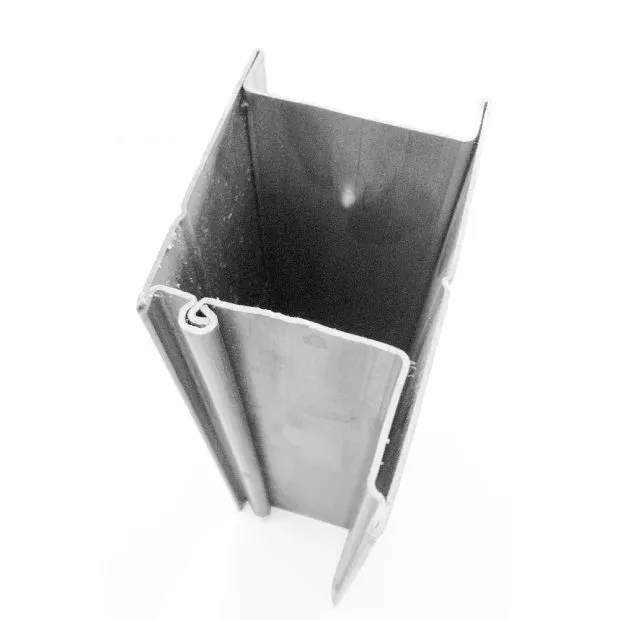

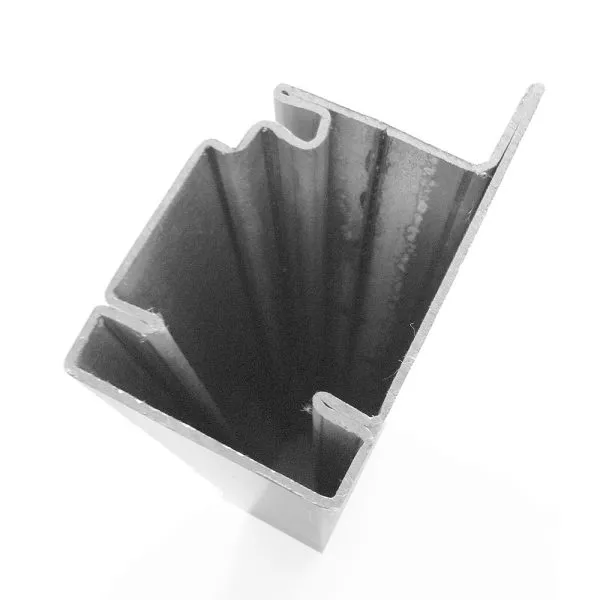

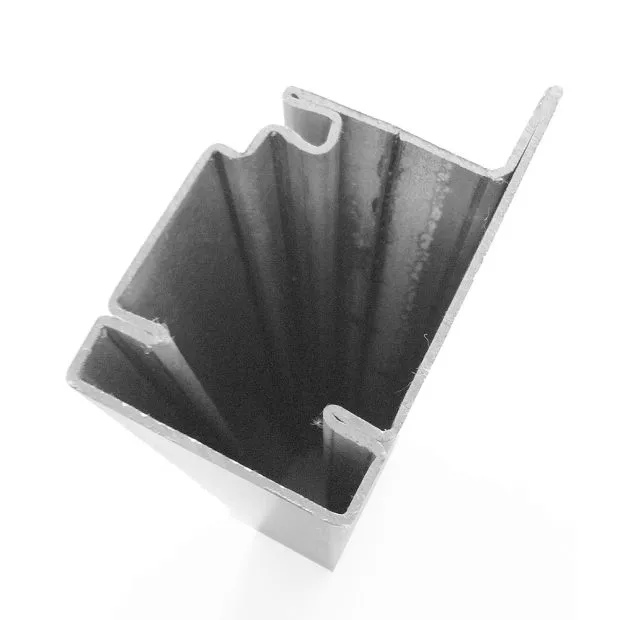

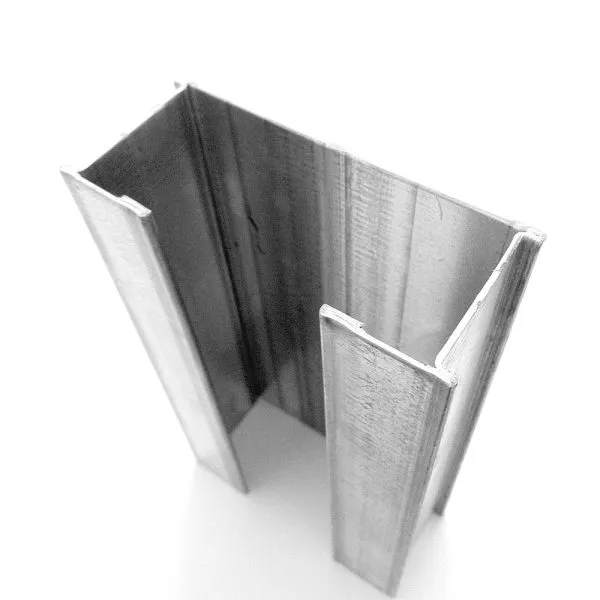

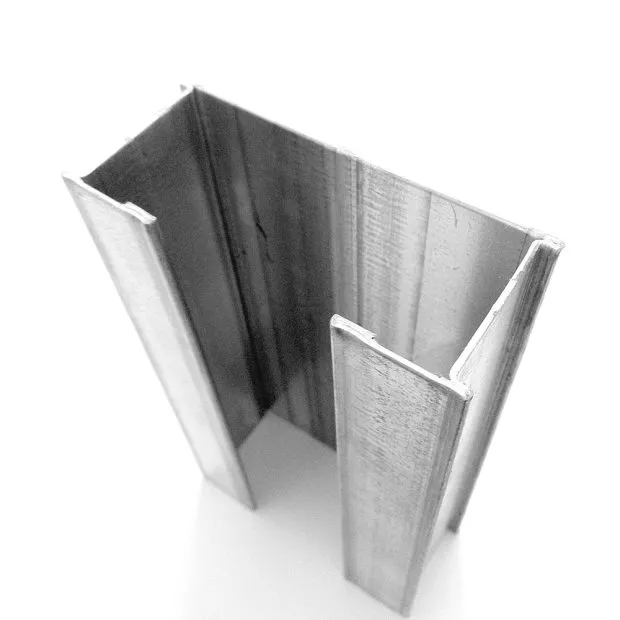

Commercial galvanized steel profiles

Profiling, stamping, punching, and bending

As with other steels, the production of galvanized steel profiles starts from sheet metal, supplied in coils and already coated with a layer of zinc. After cutting to the desired dimensions, various shapes and thicknesses can be created based on the project, ensuring maximum flexibility in terms of geometries. Galvanizing gives the metal additional protection against rust and oxidation, making the profiles particularly suitable for outdoor use or humid environments.

Cold roll forming

The galvanized sheet passes through a series of shaped rollers that gradually deform its section, allowing the creation of complex profiles while maintaining tight dimensional control.

Cold stamping

Using presses and molds, it is possible to form three-dimensional shapes with bends and ribs, meeting the needs of various industrial sectors.

Punching

Holes, slots, or various types of openings are created using precision machinery, often in line with profiling. This simplifies subsequent assembly in construction, mechanical, or light metalwork applications.

Bending

The use of rollers or specialized bending systems makes it possible to create curved or shaped profiles, which are in high demand in architectural applications or urban furniture.

The advantages of galvanized steel

Galvanized steel combines the strength of steel with effective corrosion protection, thanks to the zinc coating that prevents the formation of rust and oxidation. This feature makes it suitable for outdoor or harsh environments, offering an excellent combination of durability, practicality, and cost efficiency.

Galvanizing creates a shield against oxidation, preserving the material over time.

It helps reduce loads on structures while maintaining solid resistance.

Thanks to various processes (profiling, stamping, punching, bending), galvanized steel profiles can take on custom shapes with excellent dimensional tolerances.

The same profiles can be used in both indoor and outdoor environments due to their resistance to weathering and temperature fluctuations.

Profiles can be open or closed, with standard or custom-designed configurations. Among the most requested formats are galvanized omega profiles, highly appreciated for their Ω-shape, which provides strength and application flexibility across different support structures. These profiles are suitable for multiple uses, ensuring stability without overloading the overall structure.

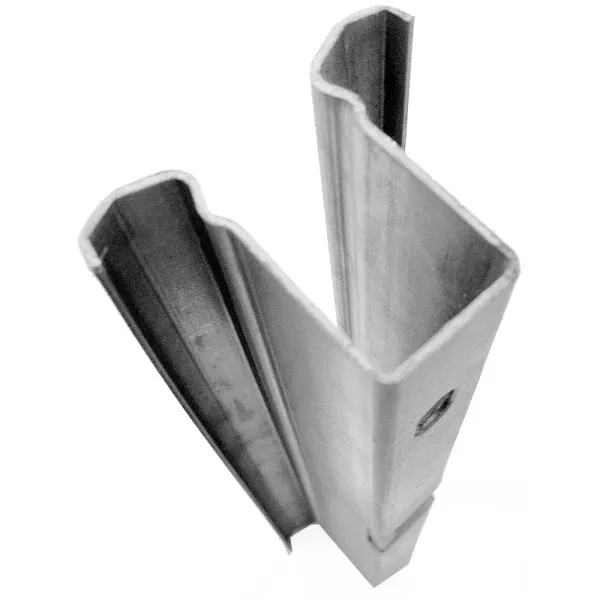

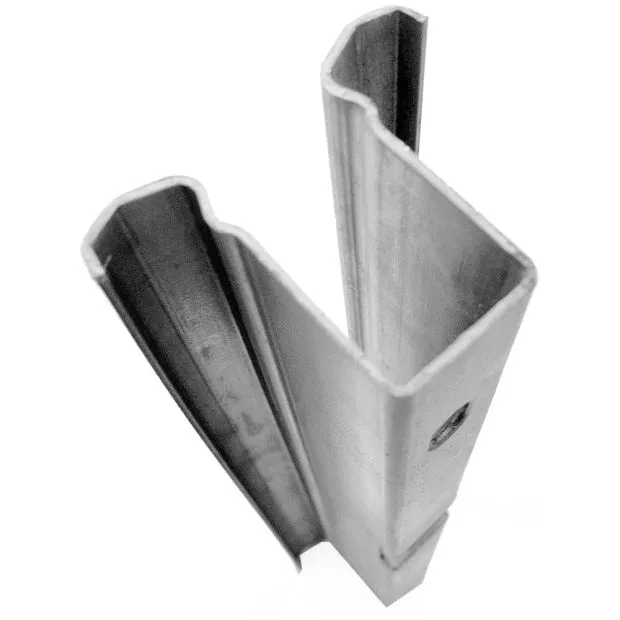

Galvanized steel vineyard posts

Galvanized steel vineyard posts are a reliable and long-lasting solution for supporting vine rows, especially in contexts exposed to high humidity and frequent temperature changes. The protection provided by the zinc layer prevents rust, reducing the need for maintenance and ensuring a long service life for support structures. Moreover, galvanized steel offers an excellent balance between strength and weight, facilitating installation and guaranteeing vine stability even in demanding environmental conditions.

Applications

Thanks to their anti-corrosion properties, galvanized steel profiles are widely used in both light and heavy construction, industrial carpentry, and urban furnishing. Galvanized profiles for window frames, for example, ensure stability and long life in humid environments, while galvanized profiles for photovoltaic systems provide ideal structural support for solar panels exposed to the elements. In interior construction, galvanized profiles for drywall allow for the easy creation of partition walls and suspended ceilings, offering excellent insulation performance. All this without overlooking the possibility of obtaining special shapes, such as the aforementioned galvanized omega profiles, suitable for various design needs.