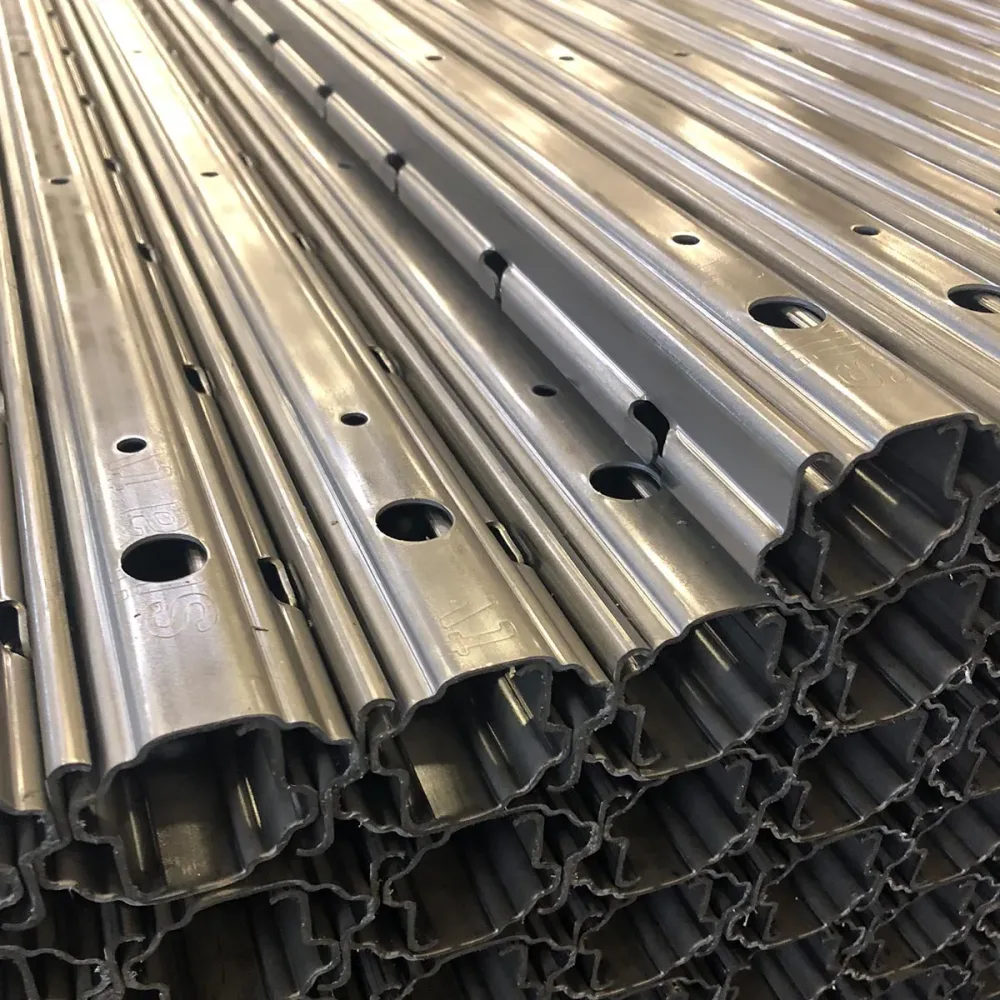

Custom stainless steel profiles

Custom stainless steel profiles: versatility and strength for any application

Custom stainless steel profiles offer a highly customizable and durable solution, ideal for numerous industrial sectors from construction to furniture, from food processing to pharmaceuticals and for any application requiring corrosion resistance, hygiene, and structural strength.

The use of stainless steel profiles ensures excellent performance in terms of corrosion resistance, durability, and cleanliness, thanks to alloying elements such as chromium that create a protective passive layer on the metal surface.

Processing technologies

Roll forming, stamping, punching, and bending

The production of custom stainless steel profiles, including those with complex geometries and specialized surface finishes, offers flexible and long-lasting solutions across many industrial and design sectors. By employing technologies such as cold roll forming, stamping, and punching, it is possible to manufacture high-performance components that meet strict tolerances and ensure high quality standards.

Cold roll forming

Cold roll forming involves passing a metal sheet through a series of rollers that gradually shape the material until the desired profile is achieved. This process ensures high precision and excellent dimensional repeatability, minimizes waste thanks to continuous and automated operation, and allows for the creation of a wide range of profiles – including open, closed, and custom-shaped sections.

Cold stamping

Cold stamping uses presses equipped with dies to shape metal sheets into more complex three-dimensional forms, often featuring pronounced bends or ribs. This method is highly effective for producing large volumes of parts, as it combines high productivity with the ability to achieve remarkable detail in the resulting geometries.

Punching

Punching enables the creation of holes, slots, or various shaped openings directly on the metal sheet, often in combination with roll forming or stamping. This process allows semi-finished parts to be preconfigured for fastenings, cable passages, or attachment systems – saving time and increasing efficiency during assembly and installation phases.

Bending

Bending is carried out using specialized machinery, such as rollers or press brakes, to produce profiles with constant or variable curves. This step adds further design flexibility, making it possible to create architectural or structural elements with smooth lines, precise curvature control, and consistent repeatability of results.

Advantages of stainless steel profiles

The raw material used to manufacture the profiles is stainless steel sheet metal, supplied in coils. Stainless steel is available in various grades such as AISI 304, 316, 430, and 201 depending on the required properties for corrosion resistance, workability, and surface finish. The sheet is cut to the necessary width to achieve the desired profile dimensions, ensuring maximum flexibility in terms of geometry and project specifications.

Thanks to the presence of chromium and other alloying elements, stainless steel forms a passive surface layer that protects the material from oxidation.

Its long service life makes stainless steel a cost-effective solution over time.

The smooth surface and resistance to chemical agents make stainless steel ideal for environments requiring high cleanliness standards, such as the food industry.

Stainless steel can undergo various finishes (polishing, brushing, embossing) to meet aesthetic or functional needs. The ability to perform cold roll forming, stamping, and punching enables the creation of complex profile shapes.

Custom-designed profiles come in various shapes to meet different technical and aesthetic requirements. Square and rectangular profiles, for example, provide the strength of a regular section and allow for flexible width and height combinations, making them ideal for structural elements and design components. Open profiles, such as channels or omegas, offer lightness and structural strength, while closed profiles typically round, square, or rectangular tubes deliver increased robustness and are used in applications subject to high mechanical stress.

Applications

Thanks to their mechanical strength and durability, stainless steel special profiles are widely used in sectors such as construction, industrial carpentry, urban furniture, and plant engineering. In the food and pharmaceutical industries, stainless steel profiles ensure hygiene and ease of cleaning. In the automotive and transport sectors, they offer structural lightness and long-term reliability. Finally, in design furniture, they provide modern and customized solutions that combine functionality and aesthetics.