Copper profiles

Copper profiles: custom solutions and top performance for every project

Copper profiles are the ideal choice for those who want to combine refined aesthetics with high performance in any application or project. Manufactured from copper coils and processed using cold roll forming, these profiles offer a unique combination of versatility and quality perfect for construction, architecture, and innovative design projects.

Processing

Profiling, stamping, punching, and bending

Copper profile production starts with the use of high-quality copper coils, a material known for its excellent conductivity, high malleability, and corrosion resistance. Thanks to copper’s inherent properties, the final product features a natural and sophisticated appearance that evolves over time through the formation of a characteristic patina, enhancing both aesthetic appeal and durability.

Cold roll forming

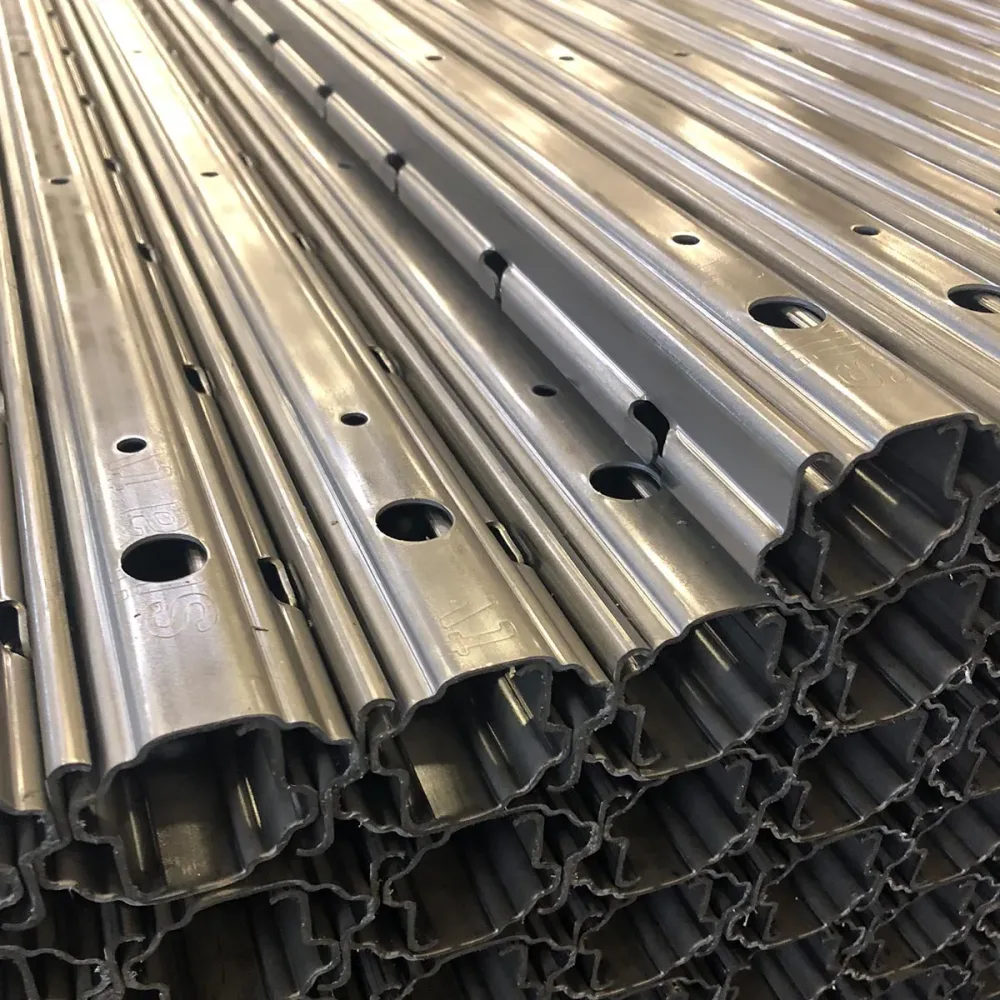

Copper sheets are gradually shaped by a series of rollers, producing open or closed sections with consistent dimensional accuracy. This technique is ideal for serial production, reducing waste while maintaining high quality standards.

Cold stamping

Using specially designed presses and molds, it is possible to create complex shapes with folds and ribs, ensuring high mechanical performance while preserving copper’s characteristic lightness.

Punching

To create holes, slots, or various openings, precision punching machines are used for fast and accurate processing. This step is essential in fields such as industrial components and furniture, where specific joints or passages are required.

Bending

Thanks to copper’s ductility, curved shapes and variable angles can be achieved, adapting the profile to the most diverse design needs. Bending allows for the creation of visually impactful curved elements without compromising structural strength.

The advantages of copper

The benefits of copper profiles stem from the union of refined aesthetics and the excellent mechanical properties of this metal. Thanks to the cold roll forming process, each copper profile guarantees precision, customization, and strength ideal for applications requiring both functionality and high visual impact.

Copper lends itself to a wide range of applications, blending harmoniously into architectural projects, interior design, and urban art installations. Cold processing enables the creation of custom, precision profiles that combine technical performance and visual appeal—offering innovative solutions that meet both functional and aesthetic needs.

Thanks to its high corrosion resistance, copper profiles are ideal for applications exposed to the elements, ensuring consistent performance over time.

Cold roll forming allows for custom shapes with high dimensional tolerances, offering tailored solutions for every project.

Types of special copper profiles

Copper profiles can be made in various configurations, ranging from open to closed solutions, and include both classic and innovative shapes. This flexibility makes them suitable for standard applications as well as custom and on-drawing projects, effectively meeting the precision and originality demands of high-end sectors.