Special aluminum profiles

Shape your ideas with special aluminum profiles: custom solutions and cutting-edge design

Special aluminum profiles offer a unique combination of structural strength, lightness, and premium finishes, making them ideal for a wide range of applications from architecture to manufacturing.

In addition to custom and on-drawing solutions, Sika also produces commercial aluminum profiles, particularly suited for serial production or projects requiring fast turnaround. Aluminum’s ease of processing and excellent recyclability help reduce production costs and environmental impact, further enhancing its value in modern and sustainable contexts.

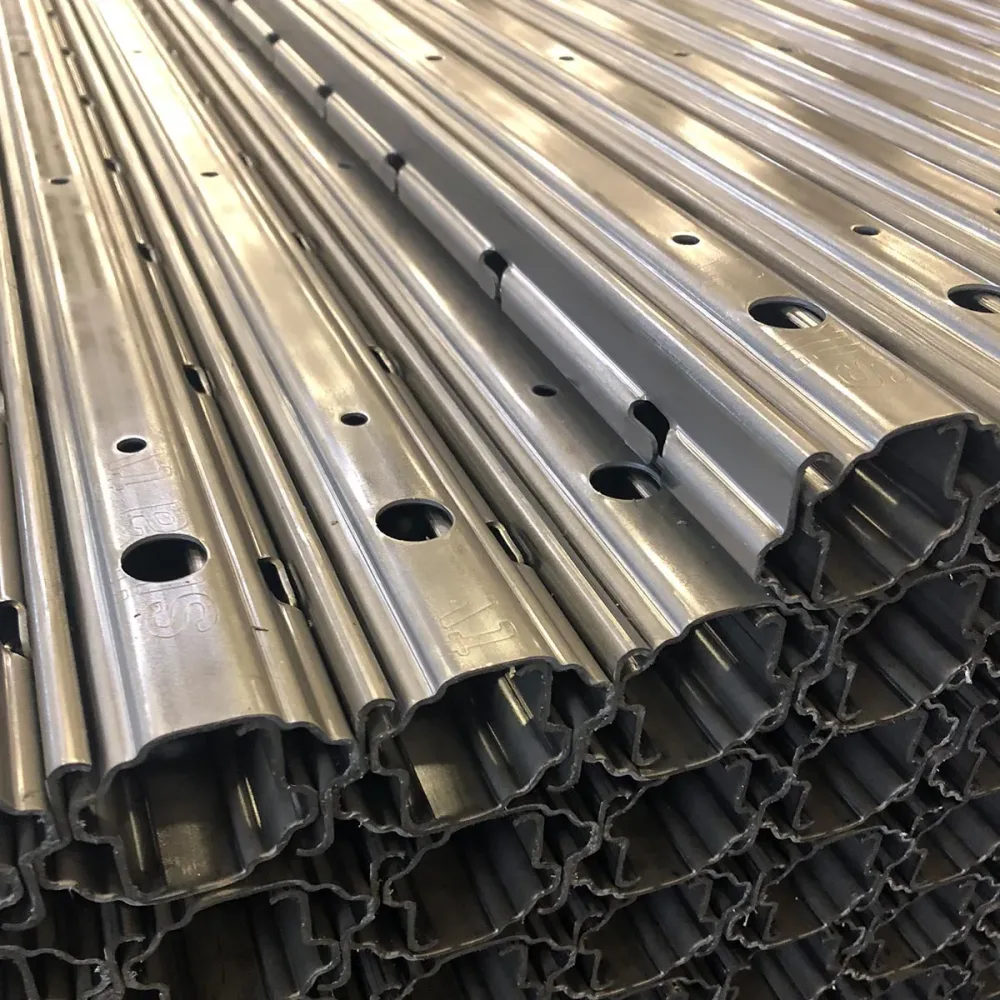

Custom cold-formed aluminum profiles

Profiling, stamping, punching, and bending

The production of aluminum profiles through cold roll forming starts from sheets and coils of various thicknesses. Aluminum naturally forms an oxide layer that slows corrosion, ensuring good resistance to atmospheric agents. Moreover, its high recyclability makes it an eco-friendly choice for those seeking innovative and environmentally conscious solutions.

Cold roll forming

Aluminum sheets are gradually shaped by a series of rollers to obtain open or closed sections with consistent dimensional accuracy. This technique is ideal for serial production, reducing waste and maintaining high quality standards.

Cold stamping

Specially designed presses and dies allow for the creation of complex shapes with bends and ribs, ensuring high mechanical performance while preserving the characteristic lightness of aluminum.

Punching

To create holes, slots, or various types of openings, precision punching machines are used to operate quickly and accurately. This step is essential in fields such as industrial components or furniture, where specific joints or openings are needed.

Bending

Thanks to the ductility of this metal, it is possible to obtain curved and angled sections, adapting the profile to various design requirements. Bending allows the creation of visually striking curved elements without compromising the structural solidity.

The advantages of aluminum

Special aluminum profiles offer an optimal strength-to-weight ratio, reducing structural loads. Aluminum is easy to process, fully recyclable, and offers excellent durability due to its natural corrosion resistance. This makes it suitable for a wide range of sectors from civil construction to automotive, from urban design to aerospace.

Aluminum offers an ideal balance between lightness and robustness, reducing structural loads without compromising stability.

The oxide layer that forms on the surface slows wear, making it ideal for outdoor environments.

From profiling to bending, processing methods allow for custom profiles for multiple applications.

Aluminum is almost infinitely recyclable without losing its properties, helping to reduce environmental impact.

Types of special and commercial profiles

In addition to producing custom aluminum profiles and on-drawing designs, we also manufacture a wide range of standard commercial profiles, ideal for conventional projects or where complex geometries are not required. Sections include channels, omega shapes, as well as rectangular or circular tubes, offering maximum application flexibility.

Painted aluminum profiles

Among the various finishing options, painted aluminum profiles add a distinctive aesthetic and additional protection against external elements. Powder or liquid coating creates a smooth, durable layer that can be customized in various colors, meeting the stylistic demands of architects and designers.

Applications

From architectural façade design to mechanical industry structures, special aluminum profiles are successfully used in environments requiring high technical performance and modern aesthetics. In window and roofing systems, they offer insulation and lightness; in furniture solutions, they combine functionality with refinement; in industrial projects, they enable the production of resistant machinery and components that remain easy to handle and install.