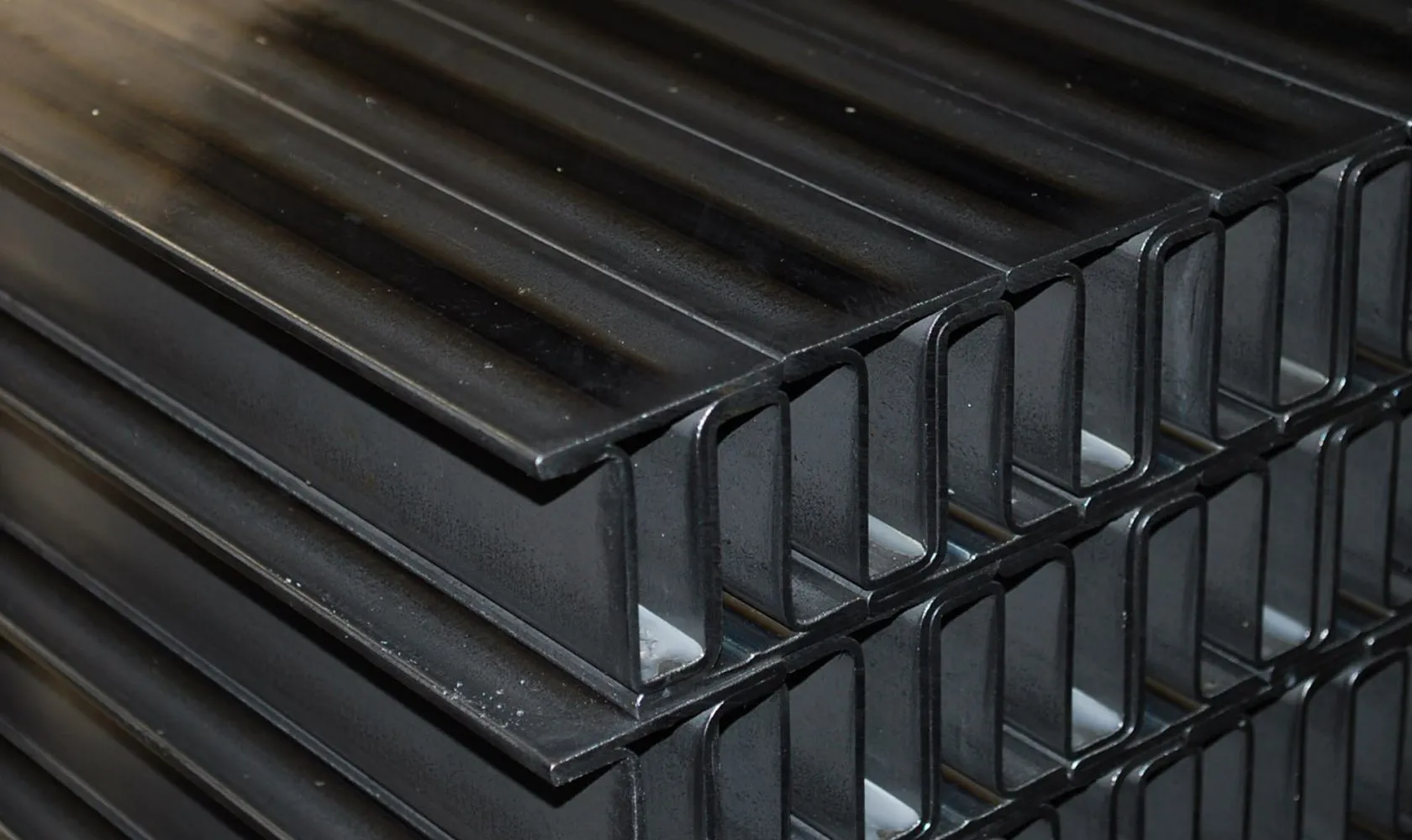

Carbon steel profiles

Black and pickled carbon steel profiles: customized solutions based on your design

Sika specializes in the cold-rolling of carbon steel profiles, including pickled and black, offering customized solutions for various industrial and architectural sectors.

Black steel is characterized by its characteristic natural dark appearance and high strength, making it ideal for a variety of carpentry and load-bearing applications. Pickled steel, meanwhile, undergoes a cleaning and anti-corrosion treatment process to ensure a more uniform surface and can easily be galvanized, painted, or chromed. In addition to these types, there is also bright steel, produced through cold rolling for a high-quality aesthetic finish and remarkable mechanical resistance.

Thanks to cutting-edge technologies, Sika is able to supply carbon steel profiles of various shapes and thicknesses, designed to meet the specific needs of construction, mechanical engineering, transportation, and street furniture. Additional processes such as bending and punching are also available to ensure maximum customization.

Advanced processing technologies

Roll forming, stamping, punching & bending

Carbon steel profiles are produced using the same processes as stainless steel, but adjusted for specific alloy properties.

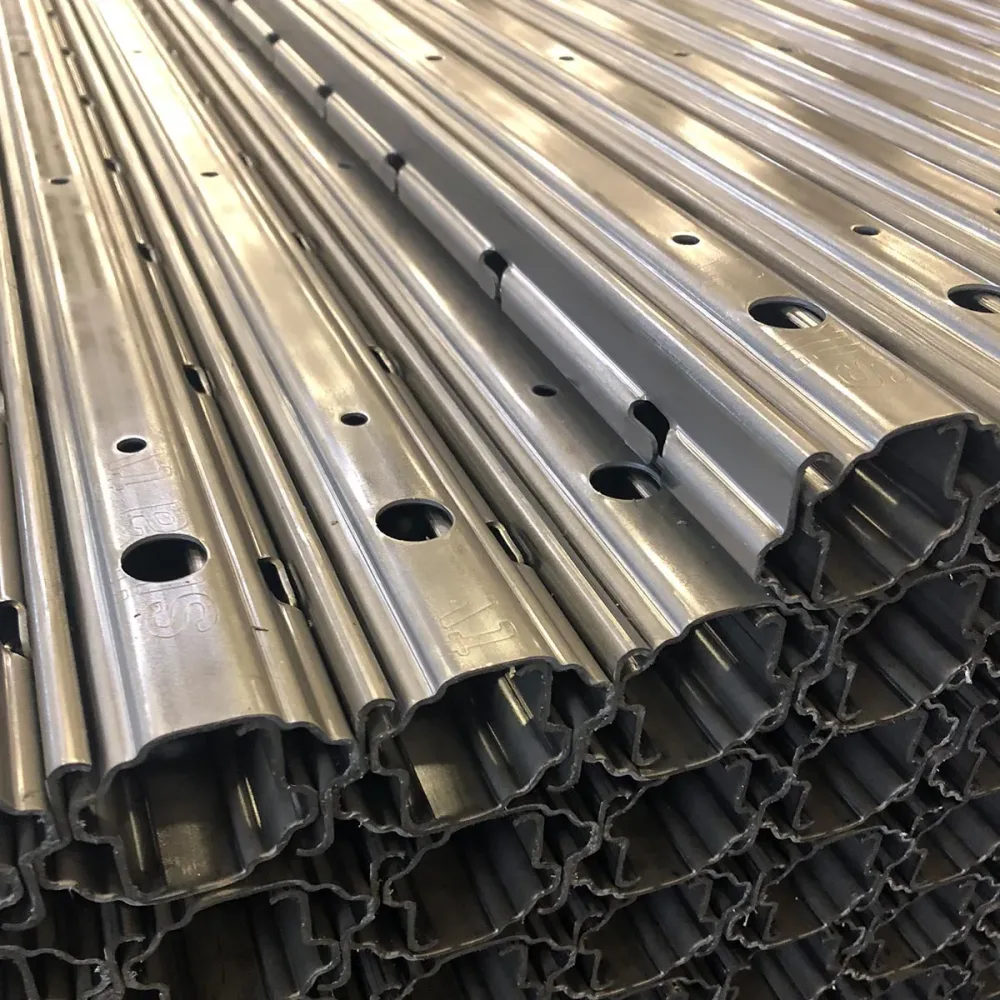

Cold roll forming

Cold roll forming involves passing sheet metal through successive rollers to shape it gradually into the final profile. This process ensures high precision, excellent dimensional repeatability, reduced waste due to continuous automated operation, and flexibility to create open, closed, or custom-shaped profiles.

Cold stamping

Cold stamping uses presses and dies to transform sheet metal into complex three-dimensional forms—such as bends and ribs. It is ideal for producing large series with high productivity and detailed geometry.

Punching

Punching enables the creation of holes, slots, or cut-outs directly on the sheet, often in combination with roll forming or stamping. This ensures pre-configured parts ready for fastenings, wiring, or attachments, streamlining assembly and installation.

Bending

Bending is carried out using specialized machinery (e.g., roll benders or press brakes) to form profiles with constant or variable curvature. It offers design flexibility for architectural and structural components, ensuring control over curvature radius and consistent results.

Advantages of carbon steel profiles

The production of carbon steel profiles begins with sheet metal, generally supplied in coils and available in various finishes (black, pickled, polished) depending on the specific surface treatments. The material is cut to size, both in length and width, to achieve the dimensions required by the project. This preliminary phase ensures maximum flexibility in terms of geometry, thickness, and tolerances, allowing us to precisely meet the technical and aesthetic needs of each application.

Carbon steel ensures structural integrity, enabling components to withstand heavy loads without deformation.

Widely available and easy to process, carbon steel profiles offer economic efficiency without compromising quality.

Suitable for cutting, welding, punching, bending, and more ideal for tailored solutions.

Supplied in black, pickled, or polished finishes with options for galvanizing, painting, and chrome plating, carbon steel profiles meet technical, aesthetic, and durability requirements.

As with stainless steel profiles, carbon steel can also be used to create open sections (e.g., U, C, omega) or closed sections (e.g., square, rectangular, or circular tubes), as well as special shapes designed for specific applications. Cold forming and other processing methods facilitate the creation of custom profiles, allowing thicknesses, widths, heights, and geometries to be defined based on project specifications.

Applications

Carbon steel profiles are used in sectors such as construction, mechanical engineering, metal carpentry, and urban furniture, thanks to their mechanical strength and ease of processing. From load-bearing structures to vehicle frames, they provide solidity and versatility, adapting to a variety of design solutions. The surfaces can be treated with specific coatings and finishes, ensuring both aesthetics and protection in the most demanding environments.