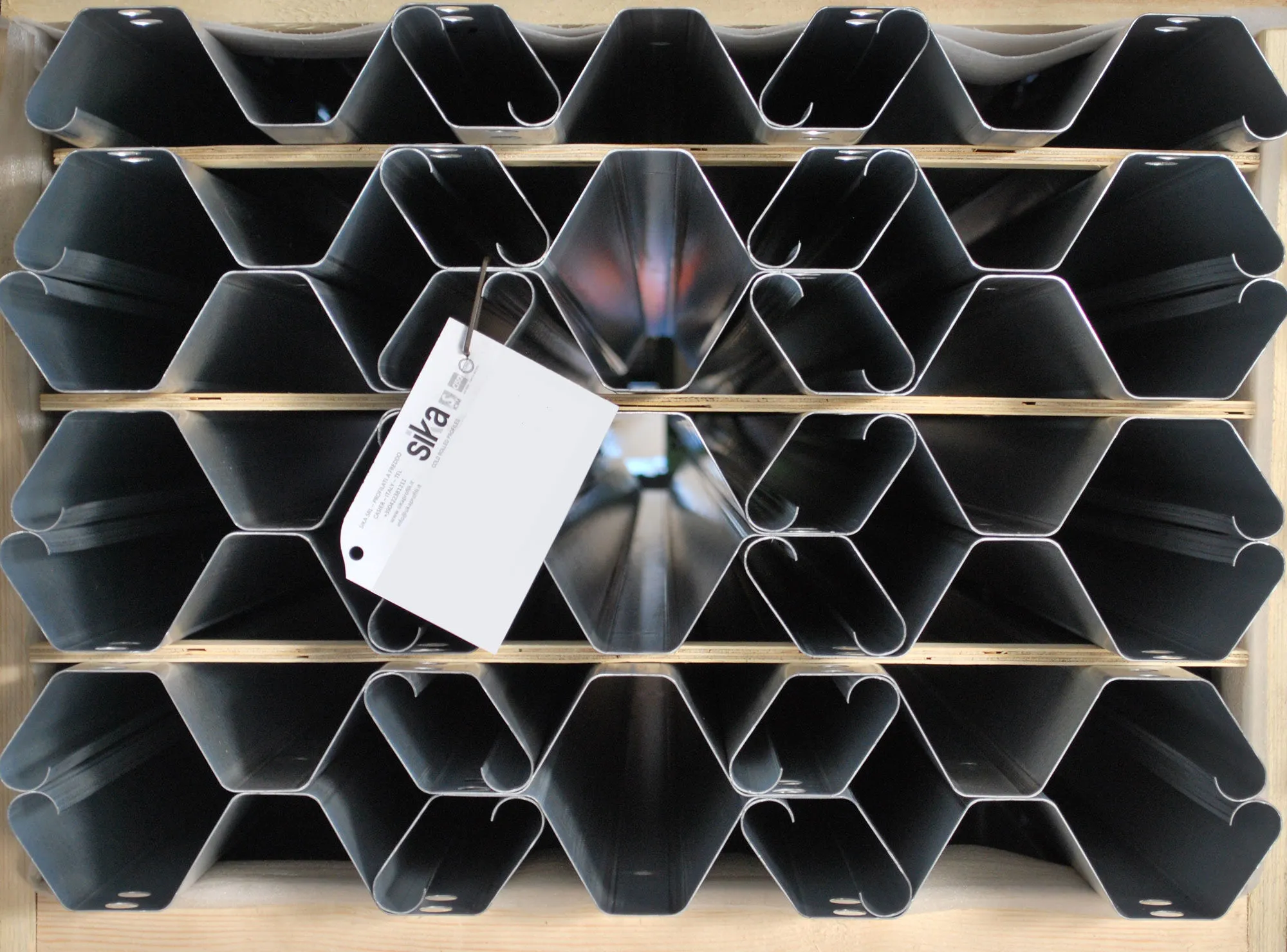

CUSTOM PROFILES

Structural aluminum profiles

Custom structural aluminum profiles. Strength and versatility for tailored projects

Sika manufactures structural aluminum profiles and commercial aluminum profiles, ideal for modular constructions, automation, technical furnishing, and industrial structures. Produced to specification, these profiles are cold-formed from high-quality aluminum alloys to ensure lightness, precision, and long-term durability.

Commercial profiles. Custom designed solutions

Alongside custom production, Sika also offers a range of custom aluminum profiles such as U-profiles, T-profiles, angle bars, tubular sections, and cable ducts. These sections are ideal for light carpentry, industrial furnishings, and quick to integrate technical solutions.

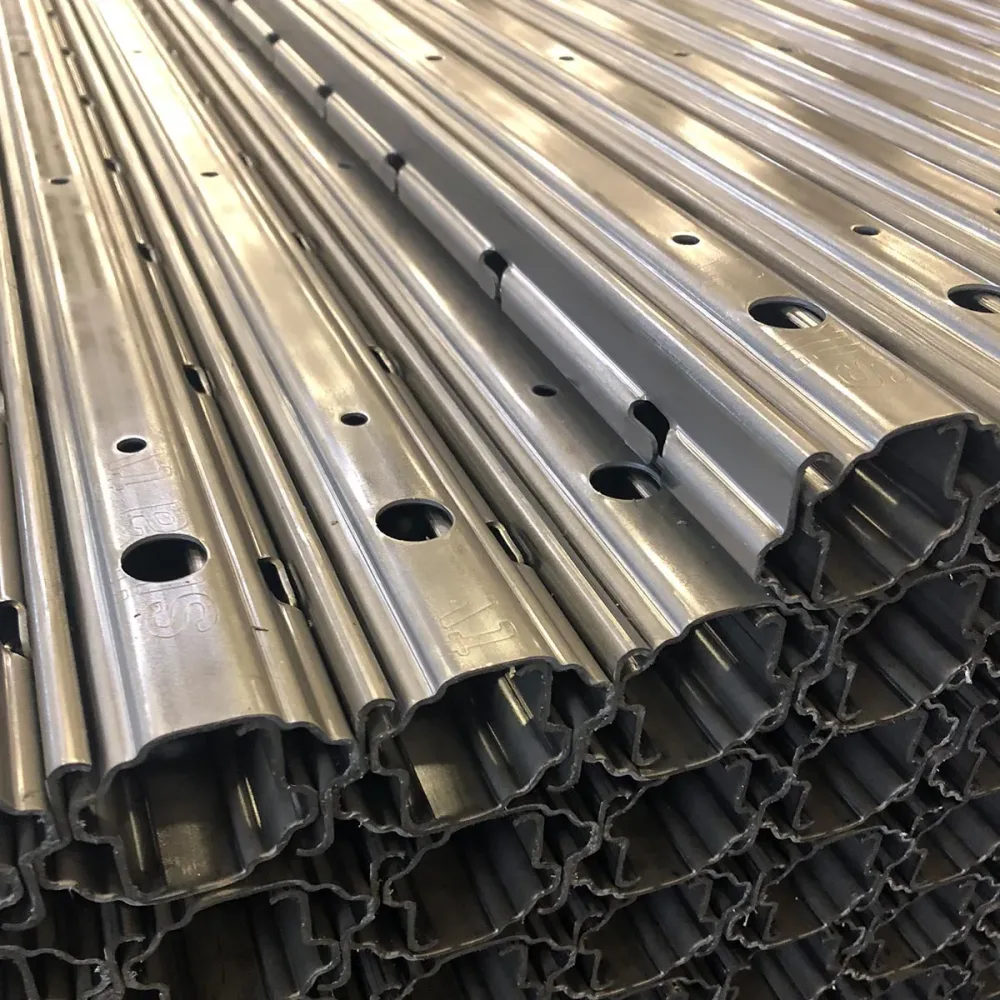

Cold forming of aluminum profiles

Roll forming, stamping, punching, and bending

Through cold roll forming, punching, cutting, drilling, and calendaring, the profiles can be fully customized to meet any mechanical or aesthetic requirement. In house processing ensures full quality control and fast delivery times.

Cold forming (roll forming)

Cold roll forming involves passing aluminum sheet through a series of rollers that progressively shape the material into the desired final profile. This process ensures high dimensional accuracy and repeatability, reduces waste through continuous automation, and allows the creation of a wide variety of open, closed, or custom shaped structural aluminum profiles.

Cold stamping

Cold stamping uses presses equipped with dies to form the sheet metal into more complex 3D shapes, often with folds or ribs. It’s an efficient solution for large production runs, offering high productivity and precision in detailed geometries.

Punching

Creating holes, slots, or various openings is essential to prepare custom aluminum profiles for final assembly or installation. In many cases, this step is performed inline, optimizing production times.

Bending

Gradual metal deformation using bending systems or rollers provides additional design flexibility, enabling the production of arches, curved sections, or highly customized shapes.

Structural aluminum profiles for robust and modular applications

Structural aluminum profiles are designed to build frames, supports, assembly workbenches, load bearing structures, and protective casings. They are widely used in mechanical engineering, logistics, internal handling systems, and industrial automation. The modularity of the sections and compatibility with accessories make structural aluminum profiles a flexible, strong, and easily reconfigurable solution.

Thanks to structural grade aluminum alloys, these profiles ensure high mechanical resistance while maintaining low weight ideal for applications that require both strength and lightness.

Anodized or coated aluminum offers excellent corrosion resistance, minimizing maintenance even in harsh or outdoor environments.

Cold forming processes allow for complex geometries and customized finishes, enabling seamless integration into technical and architectural projects.

High efficiency continuous production and minimized waste make aluminum profiles a cost effective solution even for large scale manufacturing.

Custom aluminum profiles: precision and flexibility

For projects requiring unconventional sections or specific technical details, Sika produces custom aluminum profiles based on customer drawings or technical specifications. Each profile can be completed with surface finishes (anodizing, painting), integrated machining, and compatibility with modular systems or special fastening solutions.

Fields of application

Structural aluminum profiles are used across a wide range of industries: from automated production lines to technical construction, from machinery components to technical and modular furniture. Their combination of low weight, high strength, and customization makes them ideal for applications in exhibition systems, packaging, electronics, and light mobility.

Contact us to discover how Sika can support your project with high-quality custom profiles and tailor-made solutions.

Our extensive experience, ongoing innovation, and strong presence in the industry make us the ideal partner for companies looking for high-quality structural aluminum profiles. Choosing Sika means relying on certified standards and tailor-made solutions designed to meet advanced project requirements. Discover our certifications as proof of our commitment.

Profiled materials

Discover our cold-formed materials from coils: stainless steel, pickled steel, corten, galvanized steel, aluminum, and copper. We transform metal coils into high-quality custom metal profiles, including structural aluminum profiles, tailored to meet the most diverse requirements and applications of our clients.