CUSTOM PROFILES

Custom steel profiles with bespoke design

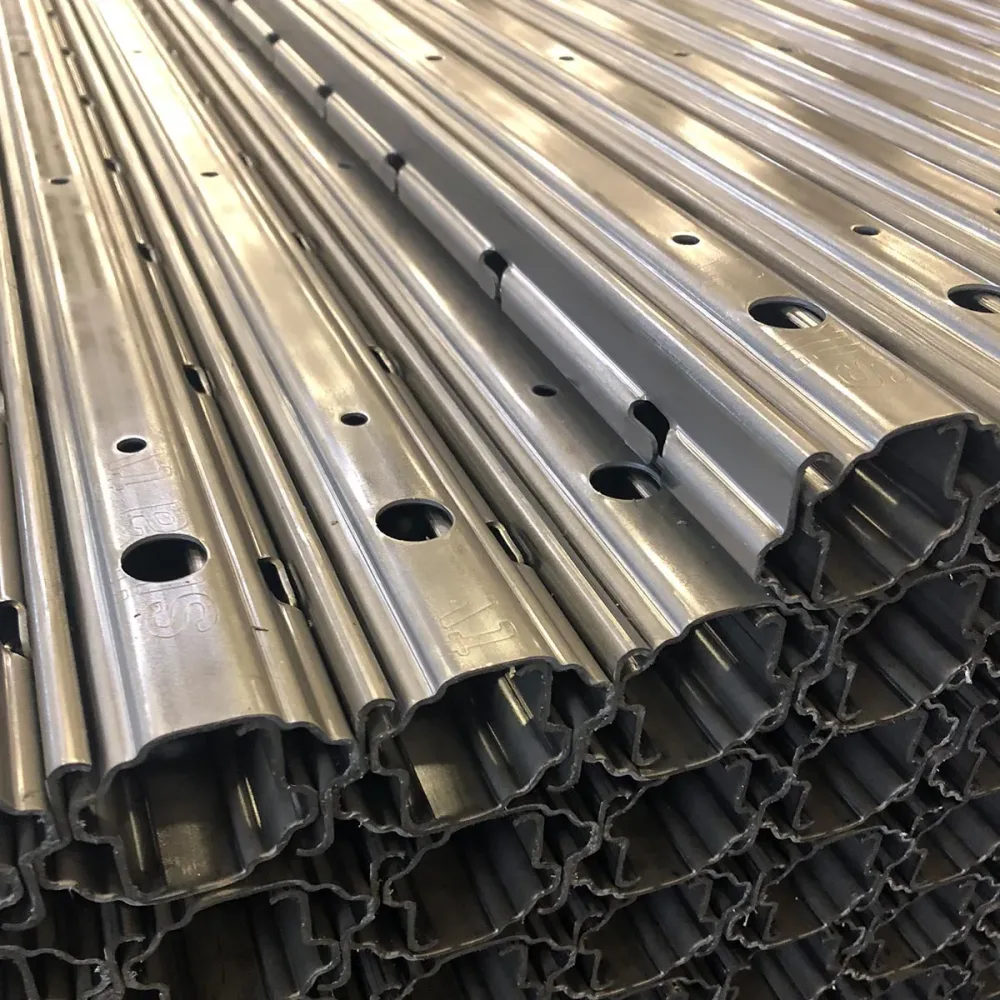

Cold formed custom steel profiles for advanced applications

Sika is a leading manufacturer of custom steel profiles, engineered and produced to meet the specific needs of industrial, construction, and infrastructure sectors. Using cold roll forming technology, each profile is crafted from coil sheet and precisely shaped to match the required geometry. This tailor-made production process optimizes every detail cross-section, length, and additional machining to ensure seamless integration and high-performance results.

Custom steel profile design with cold-formed processing

Roll forming, stamping, punching, and bending

We use technologies such as inline punching, bending, roll bending, cold stamping, and HF welding to manufacture even highly complex technical profiles. Each custom steel profile design can include holes, folds, markings, or surface treatments, ready for seamless integration into the client’s systems. All processing is performed in-house, under certified quality control.

Cold roll forming

Cold roll forming involves passing steel coil through a series of rollers that gradually shape the material into the desired final profile. This process ensures high dimensional accuracy and repeatability, minimizes waste through continuous and automated operation, and enables the production of a wide range of custom steel profiles with open, closed, or shaped sections.

Cold stamping

Cold stamping uses presses equipped with dies to shape the metal sheet into more complex three dimensional forms, often featuring folds or pronounced ribs. This method is highly effective for large-scale production, offering high productivity while allowing for detailed and precise geometries in custom steel profiles.

Punching

Punching allows for the creation of holes, slots, or various-shaped openings directly on the metal sheet, often combined with roll forming or cold stamping. This process prepares semi-finished profiles for fastening, cable routing, or mounting systems, reducing production steps and increasing assembly efficiency.

Bending

Bending is performed using specialized machines such as roll benders or press brakes to shape profiles with either constant or variable curves. This process adds further design flexibility, enabling the creation of architectural or structural elements with smooth lines, precise control over the bending radius, and excellent repeatability.

Advantages of custom steel profiles

The raw material used for custom steel profiles is sheet metal supplied in coils. Stainless steel is available in various grades (such as AISI 304, 316, 430, etc.) depending on the required strength, workability, and surface finish characteristics. The sheet is cut to the necessary width to match the desired profile dimensions, ensuring maximum flexibility in terms of geometry and project specifications.

Steel, in all its variants (corten, stainless, satin-finished), ensures high performance and reliability under heavy loads or in harsh environmental conditions.

Grades like corten and stainless steel naturally resist corrosion, significantly reducing maintenance needs over time.

Cold-forming processes allow for the creation of complex geometries and specific surface finishes tailored to both aesthetic and technical requirements.

Automated production combined with reduced waste makes custom steel profile manufacturing highly cost effective neven for large scale orders.

We manufacture profiles starting from galvanized, stainless, corten, pickled, and pre painted steel, selecting the raw material based on the intended application and the required strength and durability. We also offer special anti corrosion coatings and aesthetic finishes suitable for architectural projects and demanding environments.

Fields of application

Sika’s profiles are used across a wide range of industries: light metal structures, railings, uprights, window frames, technical furnishings, supports for industrial systems, electrical cabinets, cabin components, and modular systems. Each profile is designed to ensure structural strength, dimensional precision, and ease of assembly.

Contact us to discover how Sika can support your project with high-quality custom metal profiles and tailored solutions.

Our proven experience, ongoing innovation, and industry reliability make us the ideal partner for those seeking top level solutions. Choosing Sika for the production of custom metal profiles means relying on a company with high quality standards. Discover the certifications that confirm our commitment.

Profiled materials

Discover the materials cold-processed from coils: stainless steel, pickled steel, corten, galvanized steel, aluminum, and copper. We transform sheet metal coils into high-quality custom metal profiles that meet the most diverse needs and applications of our clients.