CUSTOM PROFILES

Custom metal profiles

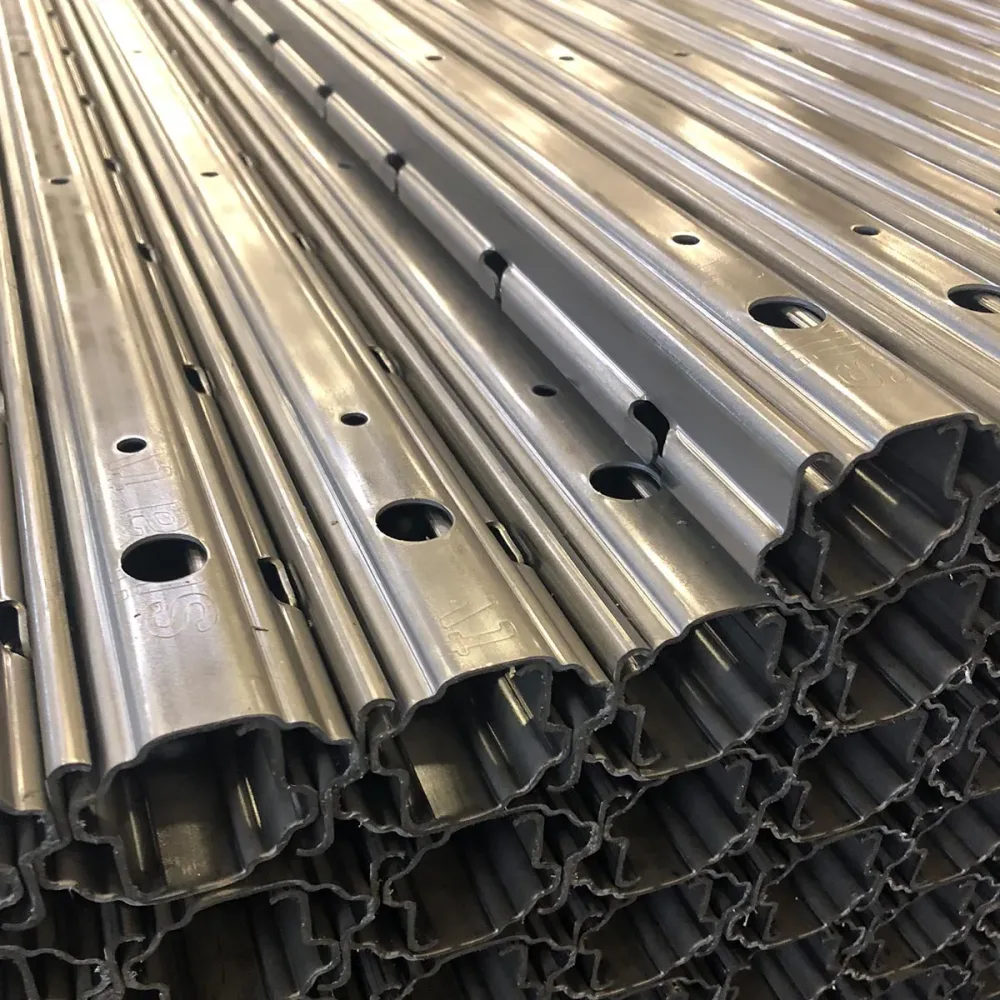

Custom metal profiles for special applications

Tailor-made solutions based on technical drawings for specialist applications.

Sika specializes in producing custom metal profiles, engineered from technical drawings and manufactured through cold roll forming. With deep technical expertise and a wide range of equipment, we can deliver bespoke metal profiles for industrial, architectural, infrastructure, and design applications. Every profile is engineered to guarantee strength, precision, and easy integration.

Cold processed metal profiles

Roll forming, stamping, punching, and bending

The production of custom metal profiles including complex geometries and special surface finishes provides flexible and long-lasting solutions across many industries. By leveraging advanced technologies such as cold roll forming, stamping, punching, bending, and curving, we manufacture high-performance components with precise tolerances and consistently high quality standards.

Cold roll forming

Cold roll forming involves feeding metal sheet through a series of rollers that gradually deform it into the final desired shape. This continuous, automated process ensures high dimensional accuracy, excellent repeatability, and minimal material waste. It enables the production of a wide variety of open, closed, or shaped custom metal profiles.

Stamping

Cold stamping uses presses equipped with molds to form complex 3D shapes, often including folds or ribs that enhance structural strength. This method is ideal for large production runs, offering high productivity and excellent detail accuracy in the resulting geometries.

Punching

Punching creates holes, slots, or custom-shaped openings directly in the metal sheet, often in combination with roll forming or stamping. This step allows semi-finished profiles to be pre-configured for fastenings, cable routing, or assembly systems, saving time and increasing efficiency during installation.

Bending

Bending is carried out using specialized machines such as rollers or press brakes to form profiles with fixed or variable curves. This process adds design flexibility, enabling the creation of architectural or structural components with smooth lines, precise radius control, and excellent repeatability.

Advantages of custom metal profiles

The raw materials used to produce custom metal profiles are stainless steel sheets (supplied in coils) and aluminum. Stainless steel is available in various alloys (such as AISI 304, 316, 430, etc.), depending on the required strength, workability, and surface finish. The sheet is cut to the necessary width to match the desired profile dimensions, ensuring maximum flexibility in terms of geometry and project specifications.

Steel in all its forms (corten, stainless, satin-finish) ensures high performance and reliability under heavy loads or harsh environmental conditions.

Variants like corten steel and stainless steel minimize maintenance needs, thanks to their inherent corrosion resistant properties.

The flexibility of cold-forming processes allows the creation of complex geometries and surface finishes tailored to specific technical or aesthetic requirements.

Automated production and waste reduction make custom metal profiles a cost effective solution, even for large-scale manufacturing.

Our selection includes not only classic carbon steels, but also premium alloys and specialized variants designed to meet precise project requirements.

Corten steel, for instance, naturally forms a protective outer layer that makes it highly resistant to weathering, while giving it a warm, distinctive appearance.

Stainless steel is ideal in environments that demand high hygiene standards or strong corrosion resistance, due to the presence of alloying elements like chromium.

Satin-finish steel, with its elegant look and low maintenance, is perfect for architectural and design focused applications.

The range also includes pickled steel profiles, which undergo specific cleaning treatments to remove oxides, leaving a surface ready for coatings or further processing.

Finally, custom aluminum profiles offer a lightweight yet durable alternative ideal for industries aiming to reduce structural weight or achieve highly complex forms.

Fields of application

Custom metal profiles are used in a wide range of fields, including architectural and load bearing structures, modular systems, electrical cabinets, automation components, and industrial furniture. They are especially valued in applications requiring custom geometries, high strength, and adaptability to non standard construction solutions.

Contact us to discover how Sika can support your project with high-quality custom metal profiles and tailored solutions.

Our solid experience, ongoing innovation, and strong presence in the industry make us the ideal partner for those seeking high-level solutions. Choosing Sika for the production of custom metal profiles means relying on a company with the highest quality standards.

Discover the certifications we have achieved as proof of our commitment.

Profiled materials

Discover the materials we cold-form from coils: stainless steel, pickled steel, corten, galvanized steel, aluminum, and copper. We transform metal coils into high-quality custom metal profiles that meet the most diverse needs and applications of our clients.