CUSTOM PROFILES

Custom aluminum profiles

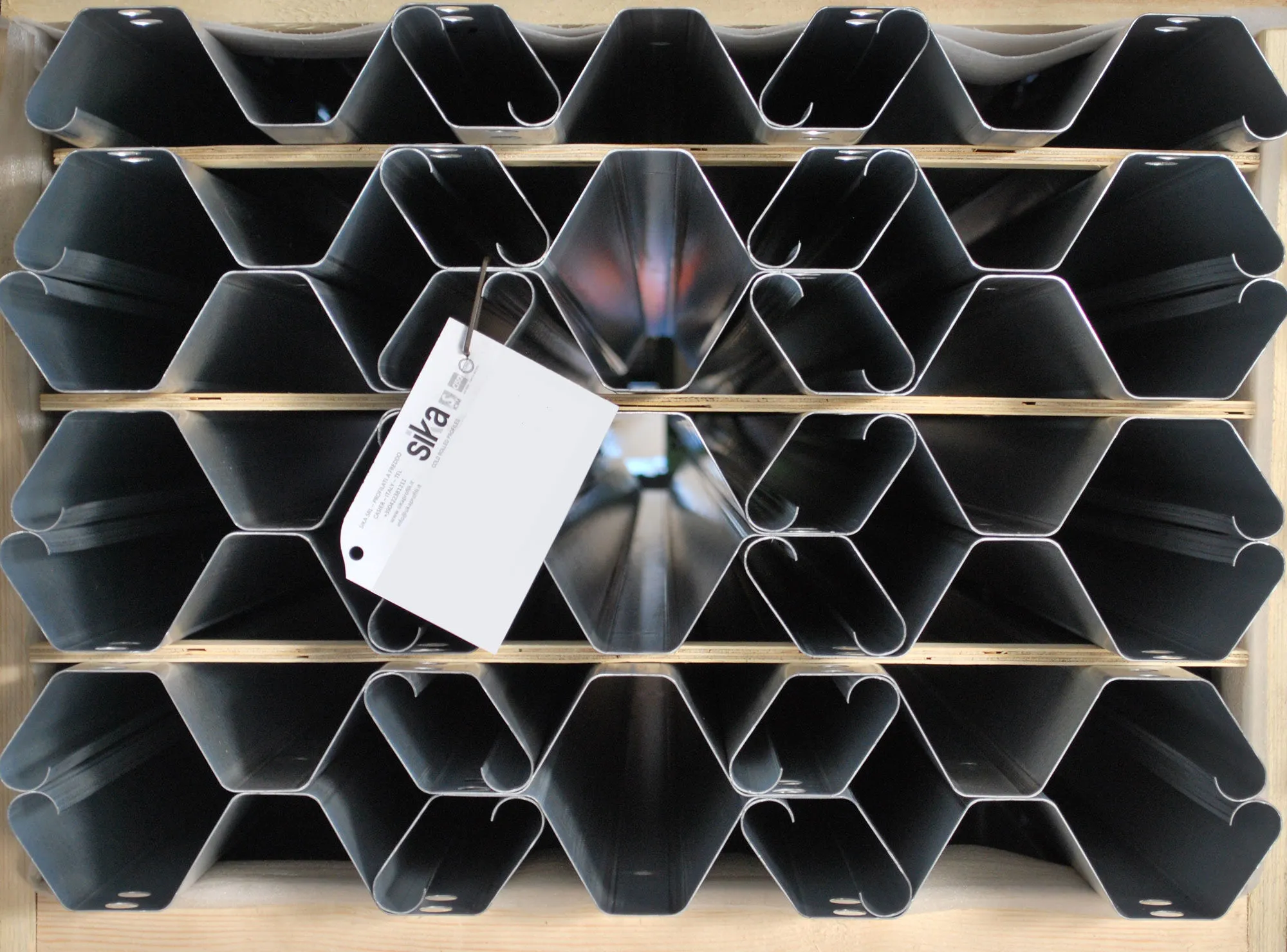

Custom aluminum solutions for tailored projects

Sika manufactures custom aluminum profiles according to your drawings, ideal for meeting requirements of lightness, precision, and corrosion resistance. Cold formed from aluminum coils, the profiles can feature open, closed, or complex cross sections perfectly suited for applications in lighting, furniture, automotive, industrial handling, and architecture. Our manufacturing processes ensure reliable, customized components ready for seamless integration into existing systems.

Cold working of custom aluminum profiles

Roll forming, stamping, punching, and bending

The production of custom aluminum profiles leverages advanced manufacturing technologies such as cold roll forming, punching, stamping, bending, and calendering. These processes allow for the creation of high-precision profiles, even with complex shapes and functional details. Continuous processing ensures high productivity and reduced waste, making aluminum profiles an efficient and sustainable solution.

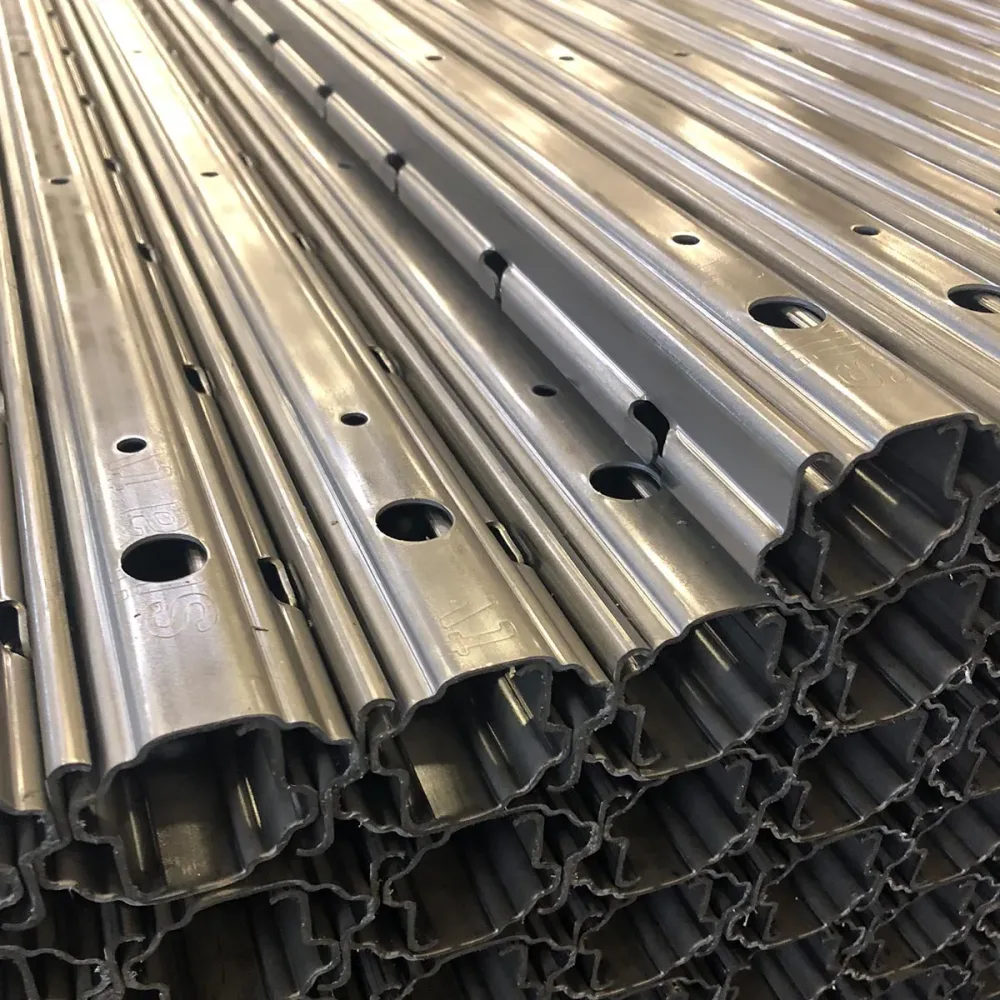

Cold roll forming

Cold roll forming involves feeding aluminum strip through a series of rollers that gradually shape the material into the desired profile. This process ensures high dimensional accuracy and excellent repeatability, minimizes waste thanks to continuous and automated operation, and enables the production of a wide range of custom aluminum profiles with open, closed, or shaped sections.

Cold stamping

Cold stamping uses presses equipped with molds to shape sheet metal into more complex three-dimensional forms, often featuring pronounced bends or ribs. This method is highly effective for large-scale production runs, combining high productivity with the ability to achieve detailed and intricate geometries.

Punching

Punching allows for the creation of holes, slots, or variously shaped openings directly on the aluminum sheet, often in combination with roll forming or stamping. This process ensures that semi-finished components are already prepared for fastenings, cable passages, or attachment systems resulting in time savings and greater efficiency during assembly and installation.

Bending

Among the key processes used to manufacture custom aluminum profiles, bending is carried out using specialized machinery such as rollers or press brakes. This step allows for the creation of profiles with constant or variable curves, offering additional design flexibility. It ensures accurate radius control and repeatability, ideal for architectural and structural components.

Benefits of custom aluminum profiles

Aluminum offers a wide range of benefits, including lightness, weather resistance, ease of machining, and excellent aesthetics. Sika’s custom aluminum profiles can be tailored with special finishes (such as anodizing or powder coating), custom cuts, perforations, or markings ensuring every technical and visual specification is met. Production is managed with strict quality controls and selected alloys, guaranteeing high performance in terms of stability and durability.

Thanks to its structural alloys, aluminum offers excellent strength while maintaining a low weight ideal for applications that require both solidity and lightness.

Anodized or coated aluminum effectively resists corrosion, reducing maintenance even in outdoor or harsh environments.

Cold processing allows the creation of custom aluminum profiles with complex geometries and tailored finishes, perfectly integrable into both technical and architectural projects.

High-efficiency continuous production and minimized waste make custom aluminum profiles a cost effective solution, even for large scale manufacturing.

Types of special and standard profiles

In addition to manufacturing custom aluminum profiles and design based solutions, Sika offers a wide range of ready to use standard profiles. These are ideal for standard projects or applications that do not require particularly complex geometries. Available sections include U-channels, omega shapes, as well as rectangular or circular tubes ensuring maximum flexibility for diverse application needs.

Applications

Custom aluminum profiles are used in a wide range of industrial sectors: in material handling as guides and supports, in automotive for lightweight and structural components, in LED lighting for frames and heat sinks, in furniture for both aesthetic and functional elements, and in construction for partition walls, frames, and window systems. The versatility of Sika profiles allows seamless adaptation to any configuration, offering ready-to-assemble components designed to optimize both installation time and cost efficiency.

Contact us to discover how Sika can support your project with high-quality special profiles and custom aluminum solutions.

Our consolidated experience, continuous innovation, and industry reliability make us the ideal partner for those seeking high-end solutions. Choosing Sika for the production of custom metal profiles means relying on a company with the highest quality standards. Discover the certifications we have achieved as proof of our commitment.

Profiled materials

Discover the materials we process through cold forming from coils: stainless steel, pickled, corten, galvanized, aluminum, and copper. We transform metal coils into high-quality custom profiles tailored to meet the diverse needs and applications of our clients.