CUSTOM PROFILES

Aluminum profile manufacturing

We manufacture custom aluminum profiles tailored to every requirement

Aluminum profile production meets increasingly diverse and complex requirements, thanks to the outstanding properties of this metal: lightness, durability, and excellent corrosion resistance.

Starting from high-quality raw materials such as sheets and coils of various thicknesses it is possible to manufacture both standard and custom aluminum profiles, with simple or complex shapes. This results in a wide range of solutions tailored to the technical specifications of every project, from construction and industry to interior design and automotive applications.

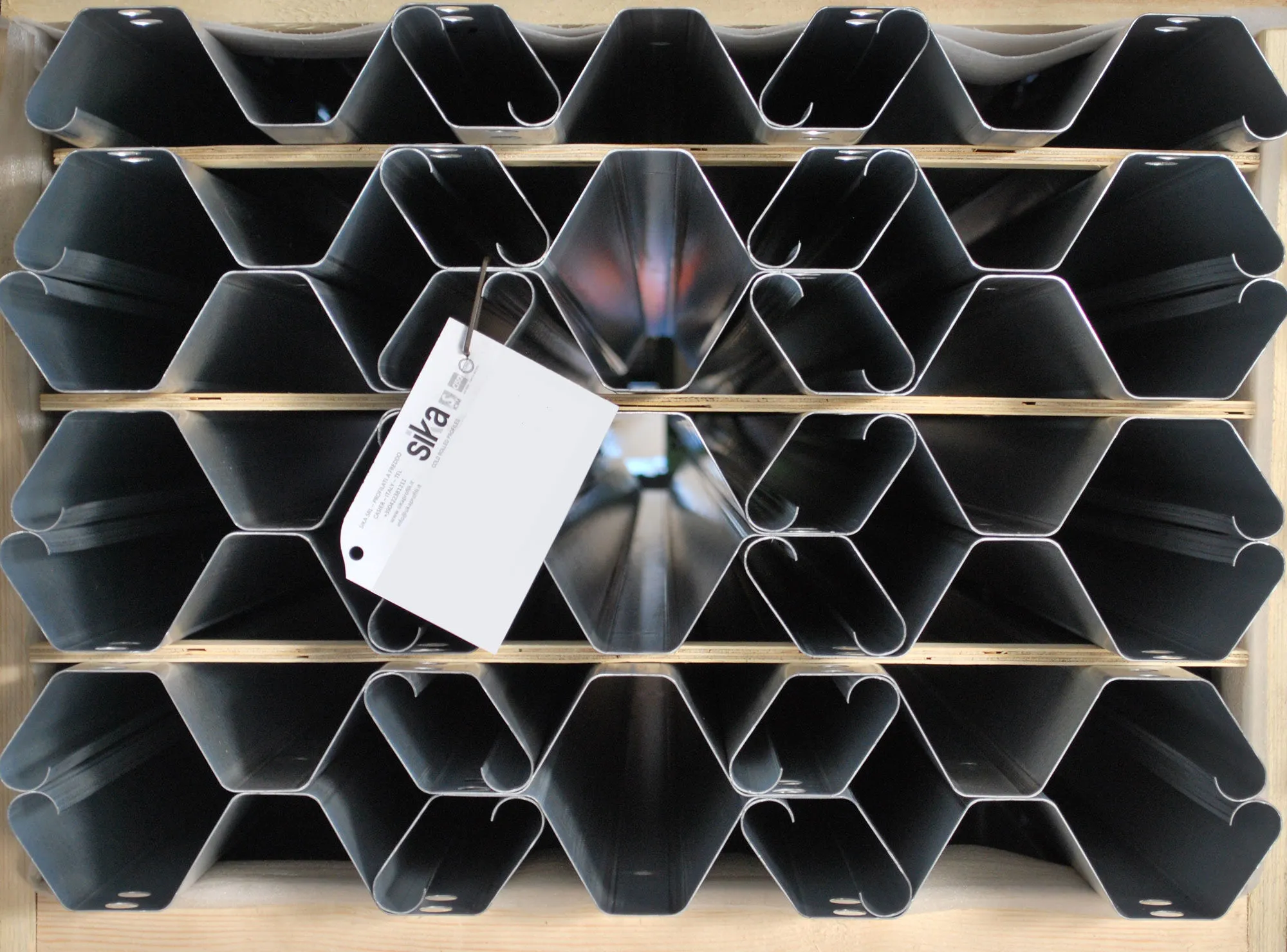

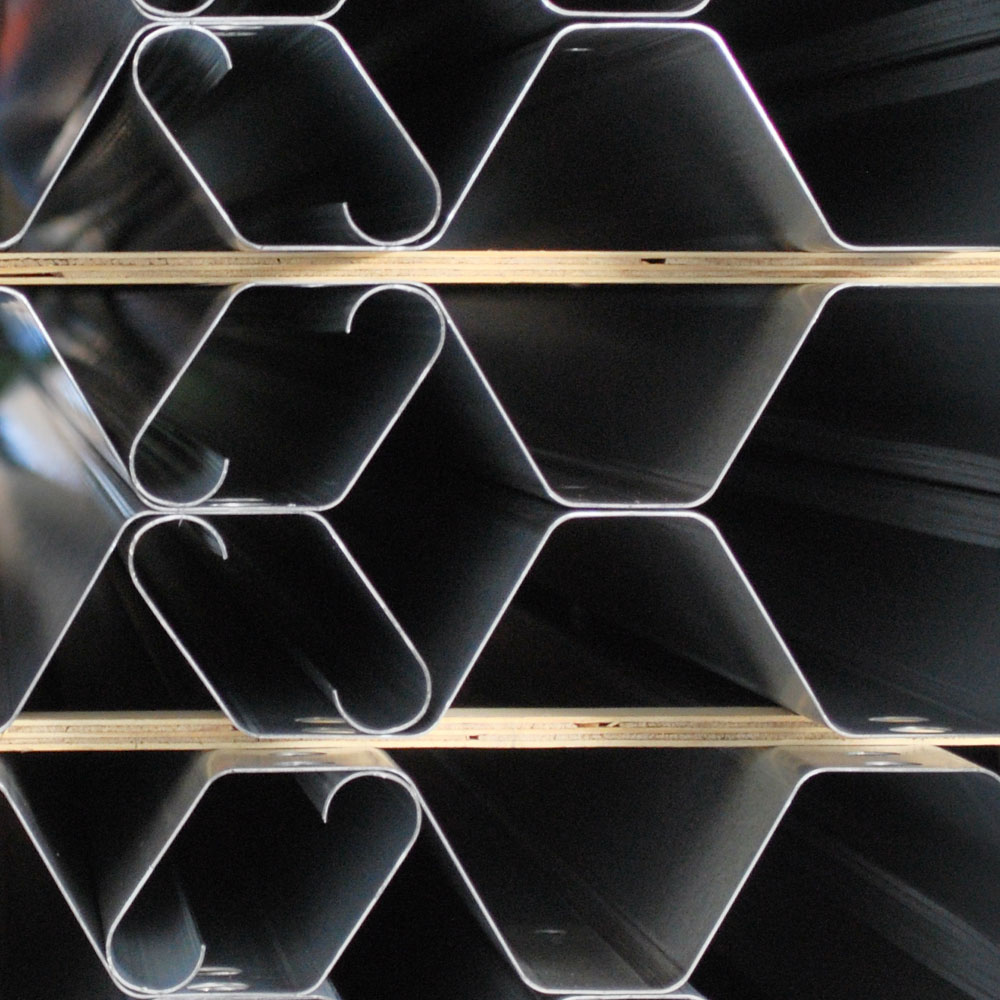

Custom aluminum profile

Roll forming, stamping, punching, and bending

The production of custom aluminum profiles offers flexible and long-lasting solutions across multiple industries. Using technologies such as cold roll forming, stamping, punching, bending, and curving, we manufacture high-performance components and accessories that meet strict tolerances and ensure high quality standards.

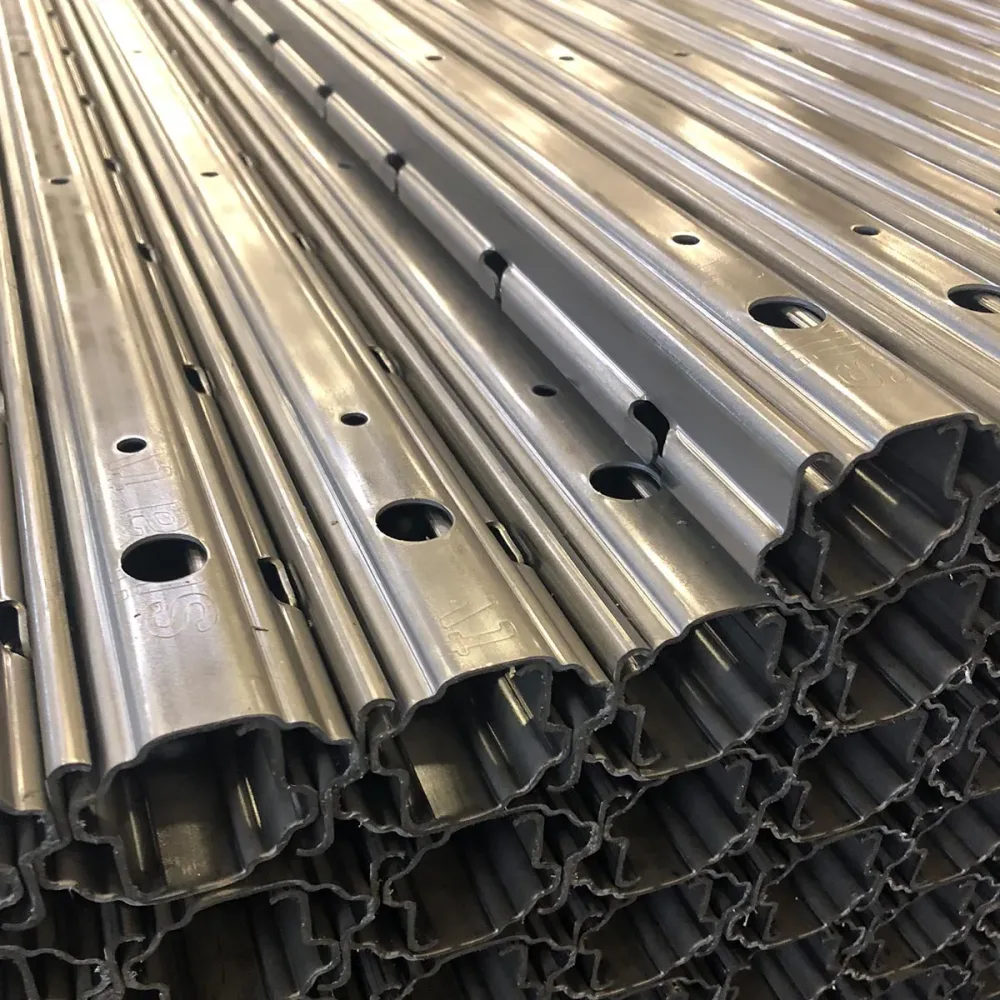

Cold roll forming (roll forming)

Aluminum coils are progressively shaped by a series of rollers until the desired profile is achieved. This process is ideal for high-volume production, ensuring top-quality standards and minimal tolerances for custom aluminum profile manufacturing.

Cold stamping

Using presses and specific molds, aluminum sheets can be shaped into complex 3D forms featuring folds or ribs that enhance structural rigidity. This method is a key step in custom aluminum profile manufacturing when high-detail components are required.

Punching

Creating holes, slots, or various openings inline eliminates subsequent processing steps, saving time and costs in custom aluminum profile manufacturing.

Bending

Thanks to aluminum’s natural ductility, it’s possible to achieve curved profiles with constant or variable radii. This capability is essential for architectural and design-focused custom aluminum profile manufacturing.

Characteristics and benefits of aluminum

Aluminum is a material that offers numerous advantages. It weighs about one-third as much as steel while maintaining high structural strength, making it ideal for applications where lightweight performance is essential. When exposed to air, it forms a natural oxide layer that protects the metal from external agents, ensuring long-lasting durability and resistance to moisture and chemicals. From a sustainability perspective, aluminum is nearly infinitely recyclable without losing its original properties helping reduce the overall environmental impact. These qualities make it a top choice in custom aluminum profile manufacturing.

Aluminum weighs about one-third of steel while retaining strong mechanical properties, making it ideal for custom aluminum profile manufacturing where structural solidity and low weight are essential.

The oxide layer that forms upon contact with air naturally protects the metal, making it suitable for many indoor and outdoor environments exposed to moisture.

From cold roll forming to punching, the available processes make it possible to create complex geometries, holes, and curves tailored to customer specifications.

Aluminum requires less deformation force, reducing production time and operational costs a key advantage in custom aluminum profile manufacturing.

To meet standard requirements, Sika provides a selection of commercial aluminum profiles (U, C, L, omega, and tubular), ready for use and suitable when complex geometries or tight tolerances are not required. However, for more specific design needs, custom aluminum profile production is the ideal solution. Starting from a concept or technical drawing, we develop profiles optimized in terms of length, thickness, and additional processes (step drilling, markings, bending), ensuring maximum customization for every project.

Applications

Our custom aluminum profiles are used across multiple sectors, including construction and architecture, mechanical engineering, furniture, automotive, home appliances, and agriculture. Thanks to a combination of advanced technologies and high-quality materials, Sika delivers solutions that integrate seamlessly into complex and innovative projects producing components that meet the highest performance standards while offering elegant and functional design. Our tailor-made solutions are engineered to meet specific requirements, supporting the development of durable, high-precision products.

Contact us to find out how Sika can support your project with high-quality special profiles and custom aluminum solutions.

Our solid experience, continuous innovation, and proven reliability make us the ideal partner for those seeking high-level solutions. Choosing Sika for custom metal profile production means relying on a company that upholds the highest quality standards. Discover the certifications that confirm our ongoing commitment.

Profiled materials

Explore the materials we cold form from coils: stainless steel, pickled steel, corten, galvanized steel, aluminum, and copper. We transform metal coils into high-quality custom profiles that meet the most diverse technical and application needs of our clients.