Custom cold-rolled profiles

Custom cold-rolled steel profiles tailored to your project

With over thirty years of experience in the industry, SIKA transforms metal coils into cold-rolled steel profiles, perfectly suited to any design or engineering need. Thanks to advanced cold forming technologies, we offer integrated solutions that combine precision, efficiency, and versatility, delivering high-quality custom metal profiles.

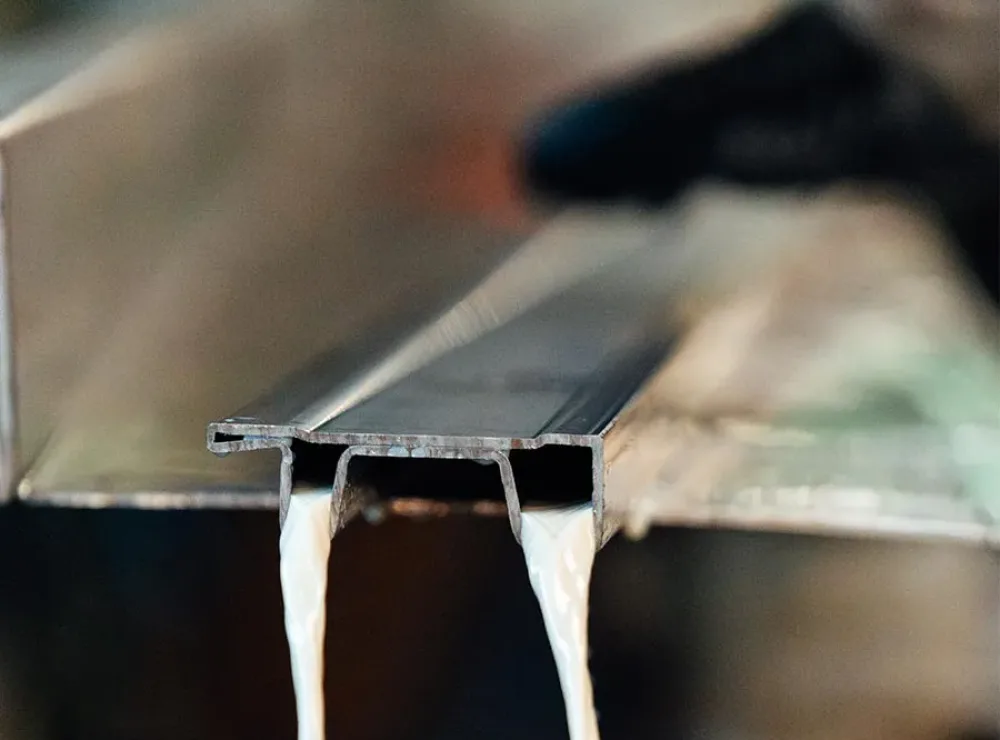

The process begins with coils of stainless steel, corten, pickled steel, galvanized steel, aluminum and copper. This allows us to produce custom-designed profiles while preserving the metal’s mechanical properties through cold processing. Our production lines are engineered to integrate multiple processes continuously and automatically, ensuring constant precision and quality at every stage.

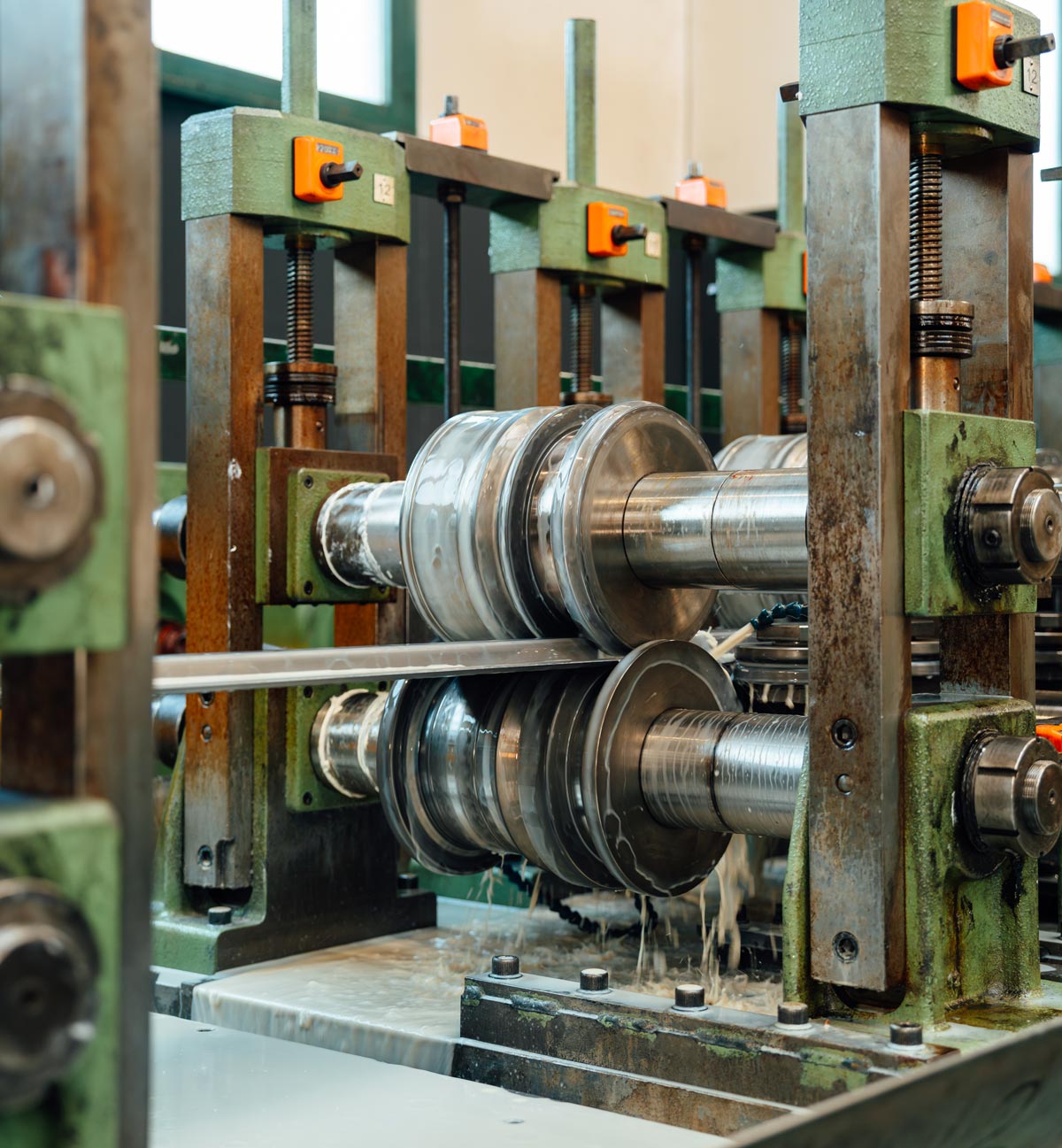

Cold roll forming

Cold roll forming transforms flat sheet metal into precise, custom profiles. This continuous process makes it possible to produce complex cross-sections with tight tolerances, ensuring high quality and production efficiency.

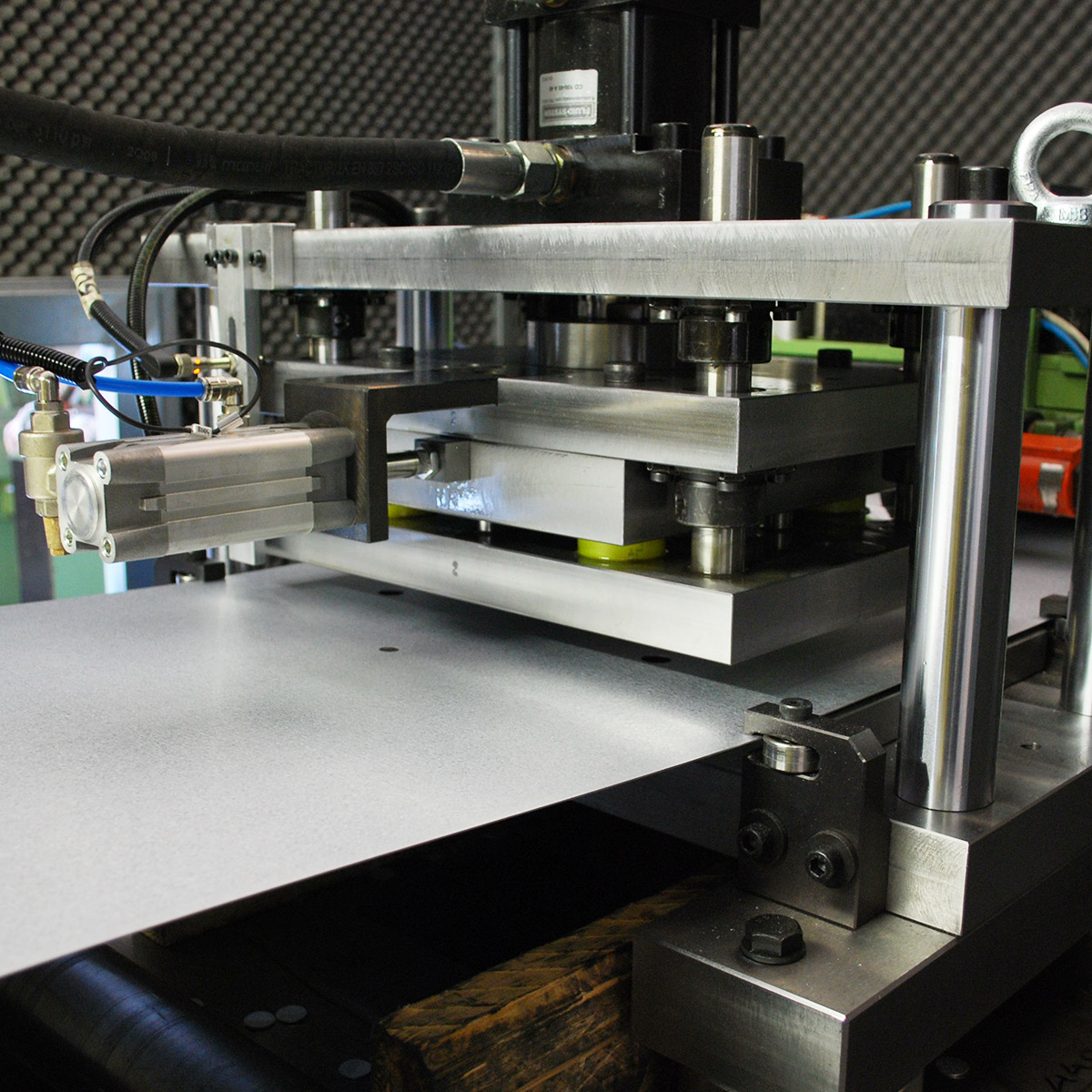

Cold stamping

Cold stamping uses presses and dies to create complex three-dimensional shapes from flat metal sheets. This technique allows for innovative geometries while maintaining structural strength and precision.

Roll bending

The roll bending process, also known as profile curving, enables us to achieve accurate radii and rounded forms. This method shapes metal into custom geometries, ideal for both architectural and industrial applications.

Punching

Our profiles can be customized with holes, slots, and other shapes using punching processes carried out before or after roll forming. All operations are performed in-line, automatically, and with micron-level accuracy through electronic control systems.

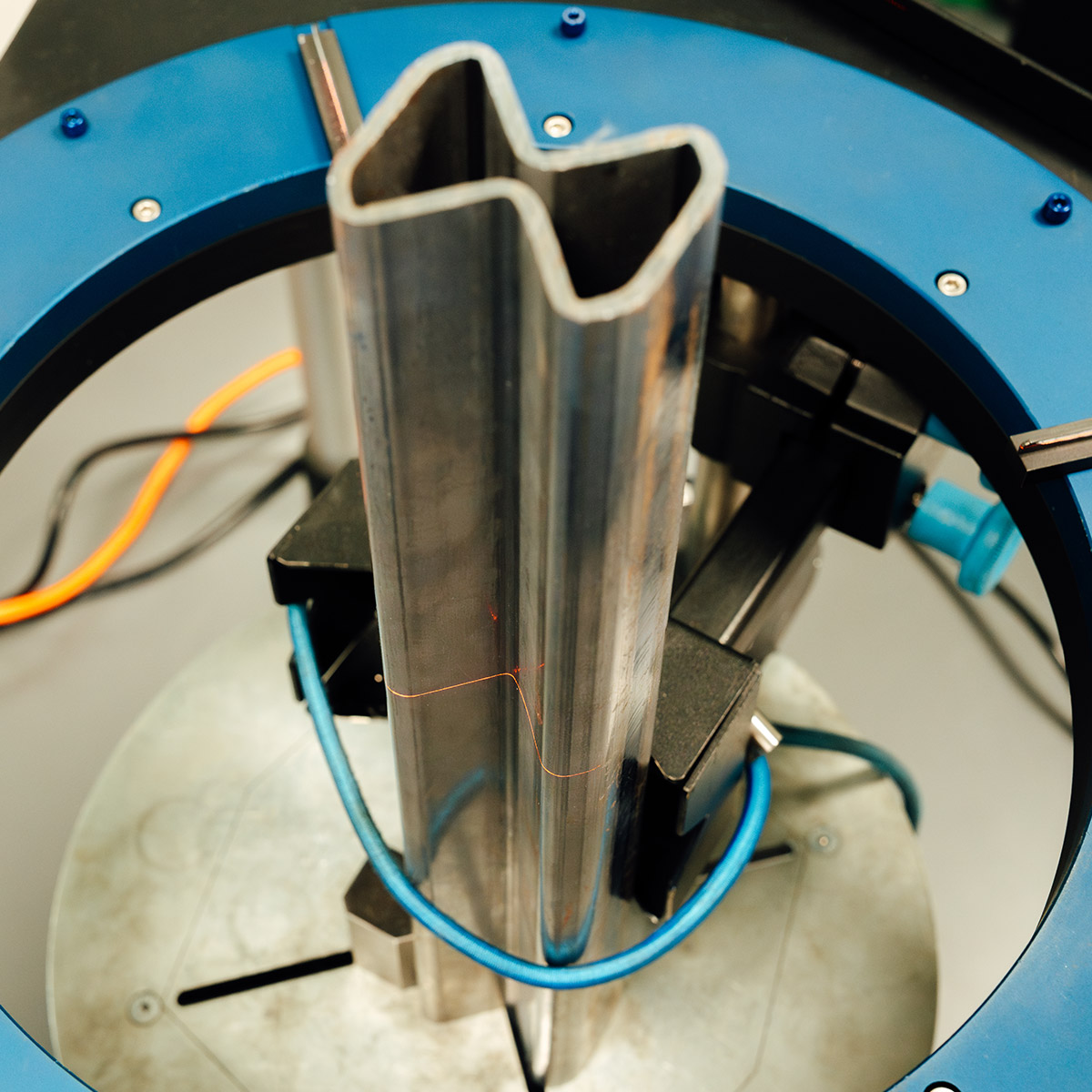

HF induction welding

To manufacture tubular profiles, we use high-frequency induction welding technology. This technique delivers high mechanical strength, high-speed production, and competitive costs.

Laser welding

We also use laser welding to produce tubular profiles with complex welding points and excellent mechanical properties.

Certified Quality control

We use state-of-the-art measuring instruments and continuous monitoring systems to ensure every profile complies with the customer’s drawings and specifications.

Thanks to flexible production batches and punctual processes, we can respond quickly to urgent needs and deliver on schedule.

The advantages of Cold Roll Forming

Cold-formed profile processing offers a strong competitive advantage, enabling the production of custom profiles in short lead times and at lower costs without compromising quality or precision. Our highly flexible production system integrates additional operations in-line, optimizing efficiency and meeting the demands of even the most complex projects.

Thanks to advanced technologies and a continuous process, we produce custom cold-rolled profiles in a short timeframe. The efficiency of our systems reduces production costs while maintaining high standards.

Our system adapts to the customer’s exact specifications, offering innovative solutions for every project.

Cold forming ensures tight tolerances and a high-quality finished product.

Possibility to incorporate stamping, punching, bending, and HF welding directly in-line to deliver complete, ready-to-use solutions.

Process

Forming, stamping, punching, and bending

Cold roll forming uses precision rollers to progressively shape sheet metal into the desired cross-section, enabling continuous production while minimizing material waste. Roll forming ensures tight dimensional tolerances and a high-quality finished product. Cold stamping makes it possible to create complex three-dimensional shapes, ideal for applications that require innovative geometries. Roll bending (also known as calendering) allows us to achieve precise curves and rounded forms in metal profiles. Punching operations integrate holes and slots directly into the production process, streamlining assembly and allowing for component customization. Profile bending is performed with advanced machinery, capable of shaping metal into specific geometries without compromising structural integrity. Finally, high-frequency (HF) welding ensures strong and durable joints, completing the production cycle and guaranteeing maximum structural strength for the finished profiles.

Cold-Rolled metal materials

To produce cold-rolled steel profiles, Sika carefully selects the most durable and reliable materials available on the market. Every step of the process is designed to ensure maximum durability and optimal performance of both cold-formed profiles and stamped components.

Application fields

Our profiles are used in a wide range of applications, from construction and architecture to mechanical engineering and urban design. Thanks to the combination of advanced technologies and high-quality materials, SIKA delivers solutions that integrate seamlessly into innovative and complex projects, manufacturing components that ensure high performance and flawless design.